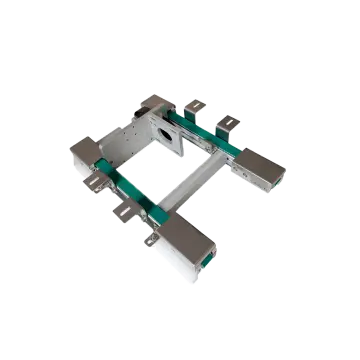

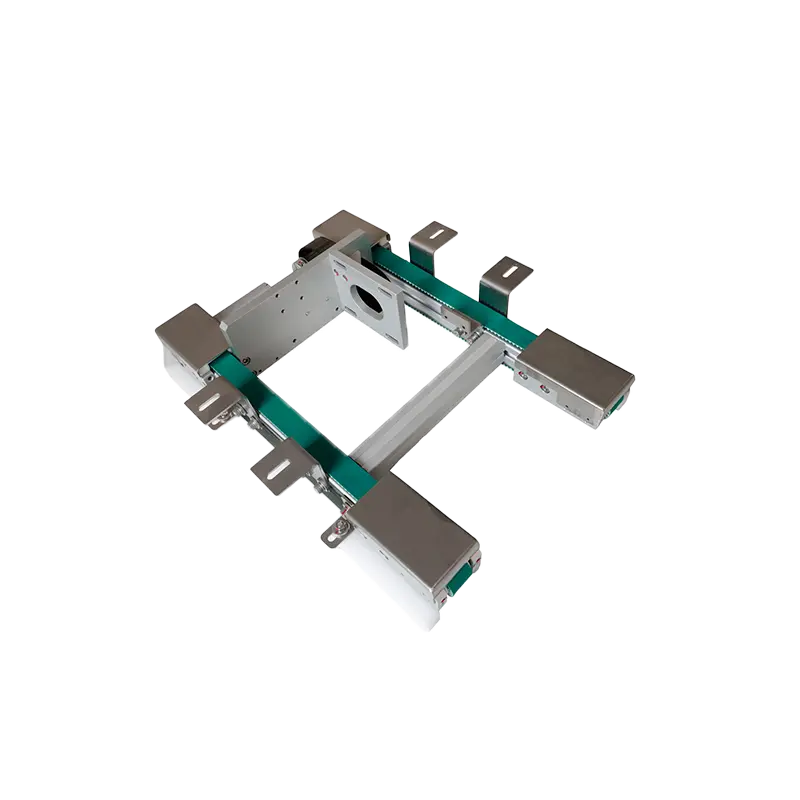

PV Wafer Cassette Conveyor Assembly

description1

description2

Core components and technological innovation

Timing Pulley System

Material: Anodized aluminum alloy/stainless steel (optional)

Tooth shape: S5M series, original rib structure design, balancing the contradiction between rigidity and lightness

Advantage: suppress resonance, ensure zero slip of wafer cassette during high-speed transmission.

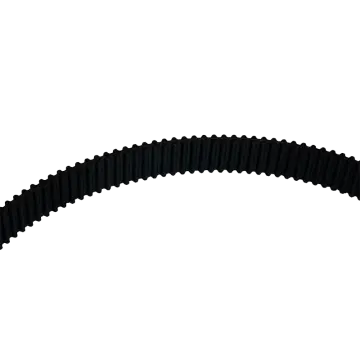

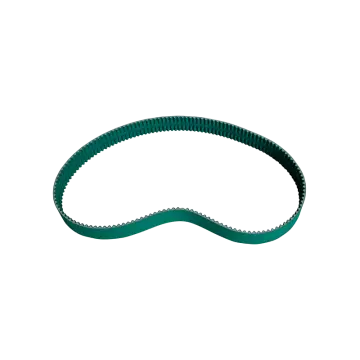

Ribbed polyurethane synchronous belt

The ribbed design eliminates the risk of collision with the basket; the grooves are anti-slip, and the power is 100% transmitted during sudden stops/speed changes

Customized rib height/spacing, precise matching of track width, support for old line reconstruction/special-shaped basket compatibility;

Heavy-Duty Bearing Housing

Using 6061-T6 aviation aluminum, the rigidity is increased by 40% while avoiding micro-deformation of the transmission shaft

Anodized surface treatment eliminates aluminum chips precipitation and avoids interference from magnetron sputtering during PVD coating

Adjustable Guide Rails

Adjustable POM wear strips to reduce damage caused by flower basket collision

Rigid guides to prevent deviation and eliminate debris caused by the wafer cassette lateral movement and collision with the guide rails (especially in high-speed turning sections)

Product categories

Application Scenario

Automated silicon wafer sorting and packaging system: realize unmanned operation of the entire process from test grading to packaging and warehousing

Adaptation to special process scenarios: TOPCon/HJT heterojunction battery transmission section, large-size/special-shaped battery cells (G12 rectangular silicon wafer/half-cell battery transportation)

Back-end intelligent management scenario: automated warehouse docking (AGV docking point to stereoscopic warehouse)

Customization of PV Wafer Cassette Transfer Assembly

The factory space is limited and the standard conveyor line cannot be installed?

The flower basket specifications are special and the existing equipment is not compatible?

The process rhythm does not match, and the accumulation/empty is serious?

The fragmentation rate is high, and the annual loss exceeds one million?

The photovoltaic wafer cassette conveyor assembly can be 100% customized according to your requirements to accurately match your plant layout, wafer cassette specifications and production capacity requirements.