0102030405

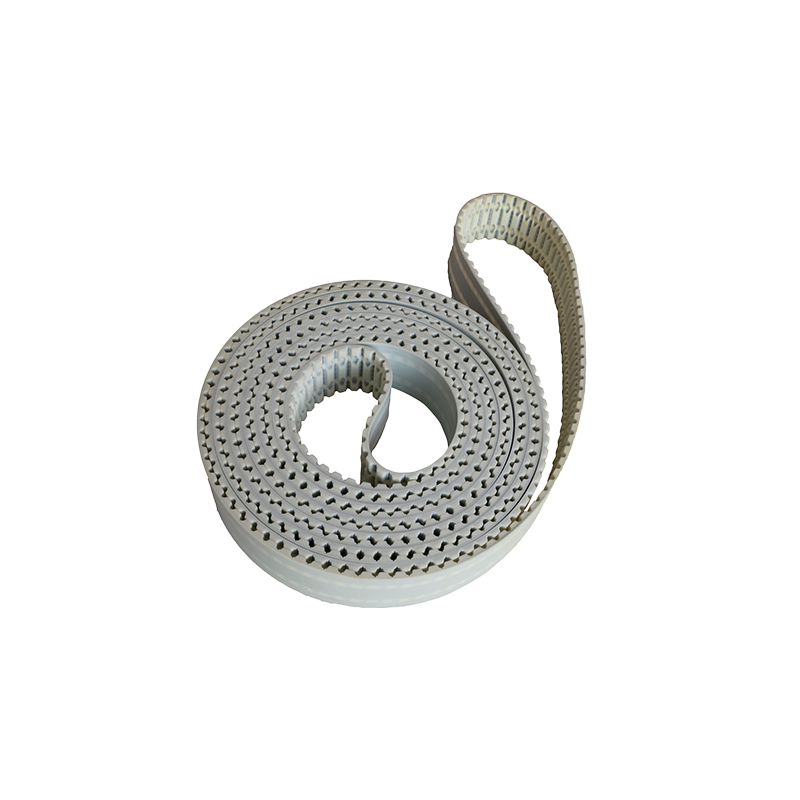

PU seamless synchronous belt | One-piece molding, zero-error transmission

description1

description2

Redefining transmission reliability - the core value of seamless technology

Seamless structure design

Through advanced one-piece molding technology, the PU seamless synchronous belt completely eliminates the weak points at the joints of traditional belts, achieves the integrity of the ring structure, improves the uniformity of tensile strength by 40%, and completely eliminates the risk of unexpected downtime caused by breakage at the joints of traditional spliced belts, with a transmission efficiency of up to 98%!

Zero interface vibration

Seamless design avoids pulse shock in power transmission and ensures smooth operation, especially suitable for high-speed precision equipment (such as CNC machine tools, 3D printers)

Ultra-quiet operation

Polyurethane material with seamless structure achieves ultra-low noise, perfectly suitable for medical equipment, laboratory instruments, office automation and other quiet and sensitive scenes.

Core technical parameters

Surface layer: high-quality polyurethane material (wear resistance coefficient 0.3, friction stability grade A)

Reinforcement layer: steel wire/Kevlar core reinforcement layer, excellent tensile strength

Tensile strength: elongation can be controlled at 5%-300%, meeting the needs of complex transmission paths.

Through advanced one-piece molding technology, the PU seamless synchronous belt completely eliminates the weak points at the joints of traditional belts, achieves the integrity of the ring structure, improves the uniformity of tensile strength by 40%, and completely eliminates the risk of unexpected downtime caused by breakage at the joints of traditional spliced belts, with a transmission efficiency of up to 98%!

Zero interface vibration

Seamless design avoids pulse shock in power transmission and ensures smooth operation, especially suitable for high-speed precision equipment (such as CNC machine tools, 3D printers)

Ultra-quiet operation

Polyurethane material with seamless structure achieves ultra-low noise, perfectly suitable for medical equipment, laboratory instruments, office automation and other quiet and sensitive scenes.

Core technical parameters

Surface layer: high-quality polyurethane material (wear resistance coefficient 0.3, friction stability grade A)

Reinforcement layer: steel wire/Kevlar core reinforcement layer, excellent tensile strength

Tensile strength: elongation can be controlled at 5%-300%, meeting the needs of complex transmission paths.

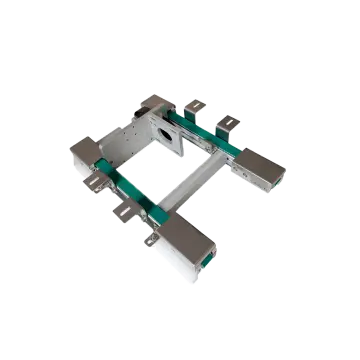

Industry solutions - precisely match your equipment needs

Medical and laboratory:

MRI machine transmission, biochemical analyzer (no particle shedding)

Food processing:

Baking production line, dairy filling equipment (can be directly washed with water, resistant to steam sterilization)

Precision manufacturing:

Semiconductor wafer handling robot, optical lens assembly line (anti-static treatment)

New energy field:

Lithium battery winding machine, photovoltaic panel lamination line (resistant to electrolyte corrosion, resistant to chemical solvents)

Advantages of PU/polyurethane seamless synchronous belt

Indicators Seamless: PU belt

Tensile uniformity: Full belt strength consistency > 95%

Transmission accuracy: Full length error < ±0.1mm

Temperature range: -30℃~+120℃ (instantaneous tolerance 150℃)

Why choose us?

Full-scenario customization:

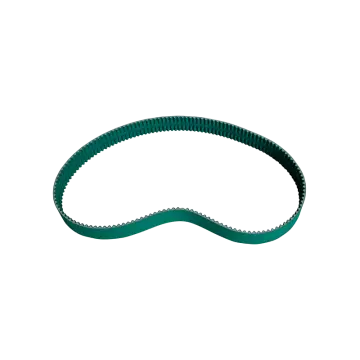

Support tooth type (HTD/STS/AT/MXL/XL/L/H/XH, etc.), color (red/blue/green logo tape), conductive/flame retardant and other characteristics customization.

Extremely fast delivery:

500+ standard specifications are in stock in Asian warehouses, and non-standard customization cycle is ≤15 working days.

Technical empowerment:

Free transmission system analysis, optimized pulley matching solution, and avoid overload loss.

Support tooth type (HTD/STS/AT/MXL/XL/L/H/XH, etc.), color (red/blue/green logo tape), conductive/flame retardant and other characteristics customization.

Extremely fast delivery:

500+ standard specifications are in stock in Asian warehouses, and non-standard customization cycle is ≤15 working days.

Technical empowerment:

Free transmission system analysis, optimized pulley matching solution, and avoid overload loss.