PU open timing belt | High-precision transmission solution

description1

description2

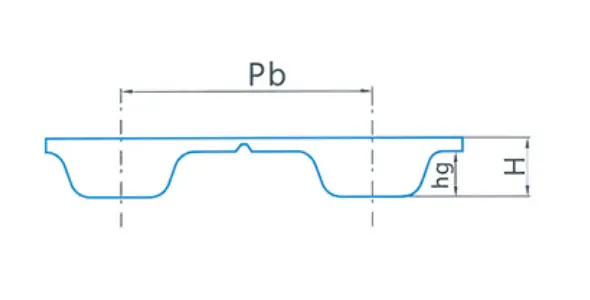

Specification

|

Type |

Pitch |

Tooth height |

Belt thickness |

STANDARD WIDTH |

|

MXL |

2.032 |

0.51 |

0.51 |

025 031 037 050 075 100 |

|

XL |

5.08 |

1.27 |

1.27 |

025 031 037 050 075 100 150 200 |

|

L |

9.525 |

1.91 |

1.91 |

050 075 100 150 200 300 400 600 |

|

H |

12.7 |

2.29 |

2.29 |

050 075 100 150 200 300 400 600 |

|

XH |

222.225 |

6.35 |

6.35 |

100 150 200 300 400 600 |

|

Type |

Pitch |

Tooth height |

Belt thickness |

STANDARD WIDTH |

|

T2.5 |

2.5 |

0.7 |

1.3 |

6 10 16 25 |

|

T5 |

5 |

1.2 |

2.2 |

6 10 16 25 32 50 |

|

T10 |

10 |

2.5 |

4.5 |

12 16 25 32 50 75 100 |

|

T20 |

20 |

5 |

8 |

25 32 50 75 100 115 |

|

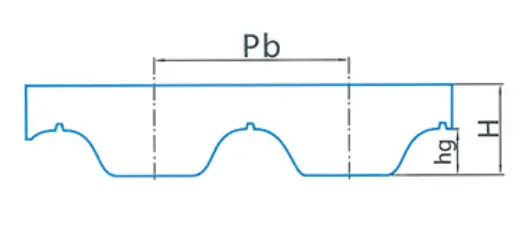

Type |

Pitch |

Tooth height |

Belt thickness |

STANDARD WIDTH |

|

AT3 |

3 |

1.1 |

1.9 |

10 20 25 50 |

|

AT5 |

5 |

1.2 |

2.7 |

6 10 16 25 32 50 |

|

AT10 |

10 |

2.5 |

4.5 |

16 25 32 50 75 100 |

|

AT20 |

20 |

5 |

8 |

25 32 50 75 100 115 |

|

Type |

Pitch |

Tooth height |

Belt thickness |

STANDARD WIDTH |

|

3M |

3 |

1.17 |

2.4 |

6 9 12 15 25 30 50 |

|

5M |

5 |

2.1 |

3.7 |

10 15 25 50 100 150 |

|

8M |

8 |

3.38 |

5.6 |

10 15 20 30 50 85 100 |

|

14M |

14 |

6.01 |

10 |

25 40 55 85 100 115 |

|

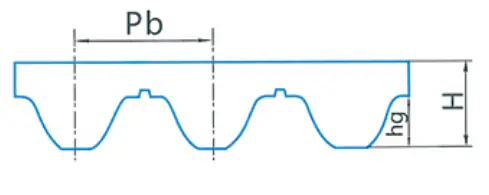

Type |

Pitch |

Tooth height |

Belt thickness |

STANDARD WIDTH |

|

S3M |

3 |

1.14 |

1.9 |

6 9 12 15 25 30 50 |

|

S5M |

5 |

1.85 |

3.35 |

10 15 25 50 100 150 |

|

S8M |

8 |

3.05 |

5.3 |

10 15 20 30 50 85 100 |

|

S14M |

14 |

5.3 |

10.2 |

25 40 55 85 100 115 |

|

Type |

Pitch |

Tooth height |

Belt thickness |

STANDARD WIDTH |

|

P5M |

5 |

2 |

3.8 |

10 15 25 50 100 150 |

|

P8M |

8 |

3.2 |

5.4 |

10 15 20 30 50 85 100 |

|

P14M |

14 |

6 |

10 |

25 40 55 85 100 115 |

Product advantages

High-strength PU material

Using high-quality polyurethane (PU) raw materials, it has the triple characteristics of wear resistance, tear resistance, and oil resistance. It is suitable for extreme environments from -30℃to 80℃, and is not affected by moisture, dust and chemical corrosion.

Convenient open design

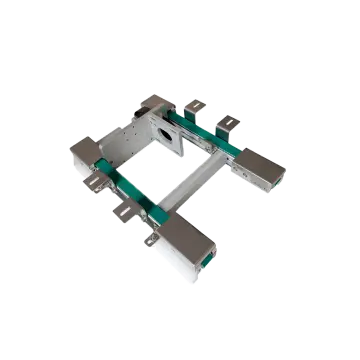

The convenient opening structure allows quick replacement of the synchronous belt without disassembling the equipment, reducing downtime losses! It supports mainstream tooth types such as HTD/STS/AT, and is suitable for precision transmission scenarios such as servo motors, conveyor rollers, and automated machinery.

Customized solutions

Provide non-standard customized services (width and length can be customized), support punching, slotting, double-sided teeth, adding blocks, adding bars, adding cloth to the tooth surface, adding cloth to the back, and covering the back with glue, etc., to meet the special needs of the food, medicine, automobile manufacturing and other industries.

Technical parameters

Tooth profile accuracy: High precision, ensuring zero slippage in transmission

Tensile strength: Good tensile strength, static elongation <1%

Applicable scenarios and industries

Food packaging machinery: filling machines, sealing machines, labeling machines (pollution-free, easy to clean)

Logistics conveying systems: sorting machines, roller lines, storage robots

Medical equipment: testing instruments, pharmaceutical equipment (quiet operation, precision assurance)

Why choose us?

Technical support: Provide one-on-one selection guidance from a professional technical team.

Cost optimization: Open design reduces maintenance costs, and bulk purchases enjoy tiered discounts.