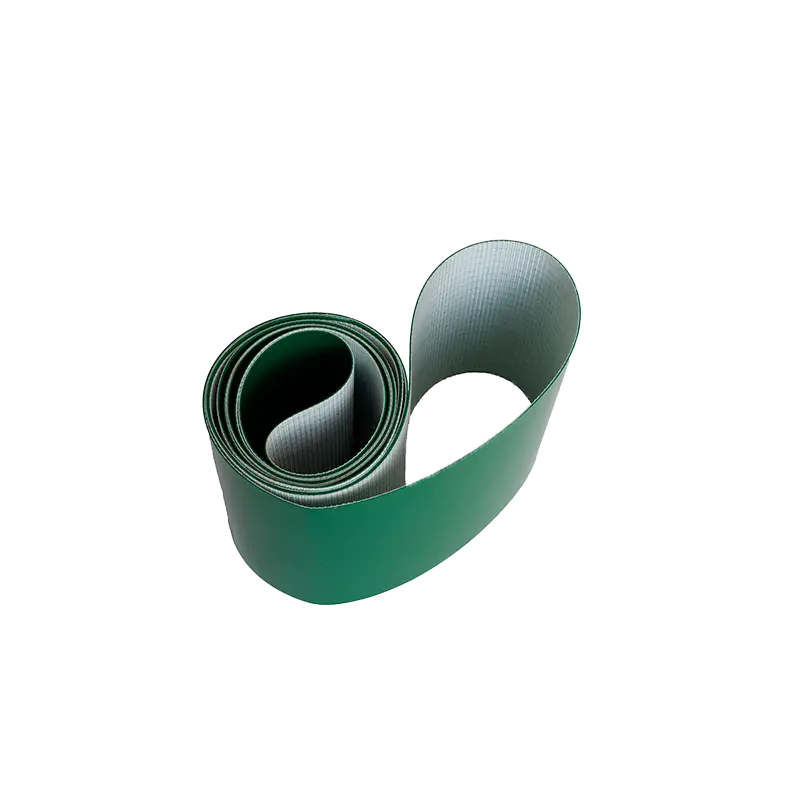

PU flat belt | High friction and zero noise transmission solution

description1

description2

Why has PU flat belt become a new trend in industrial transmission?

PU flat belt has uniform surface friction, transmission efficiency up to 98%, reducing power loss; low noise, non-lubricated design is suitable for precision production lines (such as food and electronic manufacturing) to avoid pollution risks. Support customized tooth structure to meet complex requirements such as high torque and synchronous transmission.

Lightweight design, flexible adaptation scenarios

The density is only 1/3 of rubber, which reduces the load on equipment while maintaining high strength; the thickness can be customized, suitable for all scenarios from light transportation (packaging and sorting) to heavy logistics (mines, ports). Guide strips, baffles or patterns can be added to the surface to prevent deviation and improve load stability.

Environmental protection compliance, safe and reliable

Meets the hygiene standards of the food and pharmaceutical industries. Support recyclable material options to respond to the trend of green manufacturing.

All-round tolerance performance

Chemical resistance: anti-grease, weak acid, solvent corrosion

Temperature resistance: no brittle cracking at -30℃, no deformation at +80℃

Technical parameters and certification

Surface: high elastic polyurethane (hardness 80A-95A optional)

Surface characteristics: optional smooth surface/rough surface/static conductive

Six core application scenarios

Precision material transportation:

3C electronic component transmission, photovoltaic panel lamination line (surface without marks, protection of sensitive materials)

Food processing line:

Bread baking line, seafood sorting machine (can be directly rinsed, mildew and antibacterial)

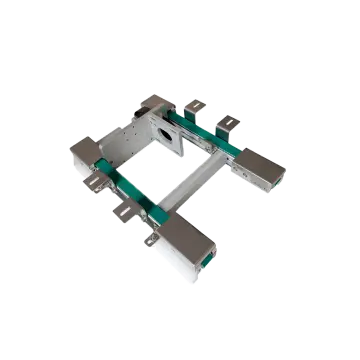

Automated warehousing:

AGV trolley loading platform, stereoscopic warehouse conveyor (high friction and anti-slip)

Printing and packaging:

High-speed labeling machine, carton sealing line (precise positioning, zero deviation)

Medical equipment:

Test tube filling system, surgical instrument assembly line (clean room grade dust-free standard)

Heavy industry:

Automotive parts grinding line, metal sheet handling (resistant to metal debris wear)

Advantages of PU/polyurethane flat belts

Indicators: LP PU flat belts

Surface adhesion residue: The belt surface is smooth and does not stick to materials, just wipe it clean with a damp cloth

Adaptability to low temperature environment: -30℃ maintains elasticity, traction does not decrease

Long-term use cost: Comprehensive cost reduced by 65%

Customization flexibility: 72-hour quick feedback OEM customization

Why choose us?

Quality certification: More than 20 years of experience in polyurethane material research and development, ISO 9001 quality certification.

One-stop customization service: Provide full-process services from selection consultation, size customization (width, length, color) to fast delivery, 72 hours for sampling, 7 to 25 days for global delivery.