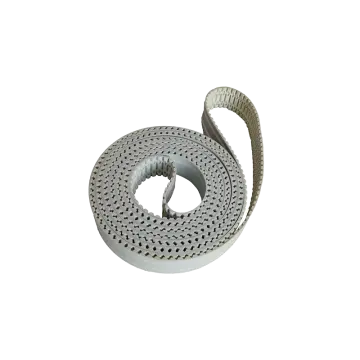

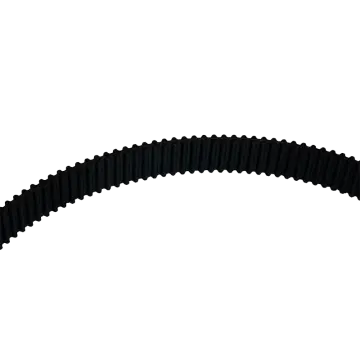

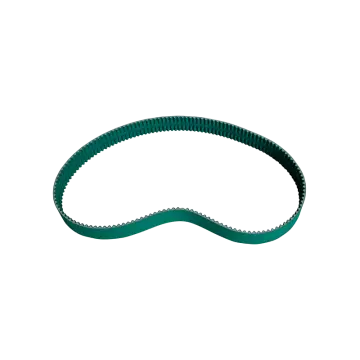

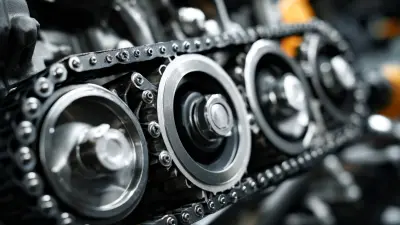

High-Quality Polyurethane Synchronous Belts for OEMs, Factories & Exporters

Reliable performance and durability are essential in machinery components, and polyurethane Synchronous Belts stand out in this regard. Engineered for optimal functionality, these belts ensure smooth operation while minimizing wear across various applications. As a supplier, I provide a selection of high-quality options that are cost-effective. Working closely with exporters, I focus on delivering exceptional value without compromising on standards. At Nantong Lanpeng Intelligent Machinery Co., Ltd., I emphasize catering to diverse needs by supplying a comprehensive range of polyurethane synchronous belts designed for specific requirements.

In-Depth Analysis of Methods Polyurethane Synchronous Belt Service Backed by Expertise Your End-to-End Solution

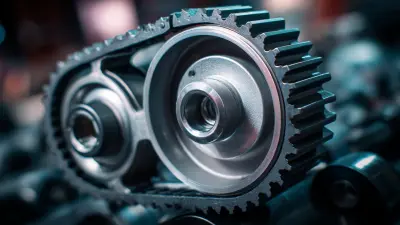

In the rapidly evolving landscape of industrial machinery, the choice of components plays a critical role in operational efficiency and overall performance. Among these components, polyurethane synchronous belts stand out due to their unique properties, including durability, flexibility, and resistance to wear and tear. This analysis delves into the various methods of servicing these belts, ensuring they perform optimally throughout their lifecycle and are supported by expert insights for a comprehensive solution. Effective service methods for polyurethane synchronous belts encompass regular inspections, meticulous maintenance routines, and timely replacements. By implementing a proactive service approach, businesses can minimize unexpected downtimes and enhance production efficiency. Furthermore, leveraging expert knowledge can lead to informed decision-making regarding the best service intervals and replacement strategies based on individual operational demands. This not only extends the lifespan of the belts but also contributes to a more sustainable production process. Ultimately, investing in the proper servicing of polyurethane synchronous belts aligns with the broader goals of maximizing productivity while minimizing costs. By understanding the best practices and integrating expert-backed strategies into maintenance protocols, procurement professionals can ensure their operations remain competitive in the global marketplace, driving both innovation and efficiency forward in their industries.

In-Depth Analysis of Methods Polyurethane Synchronous Belt Service Backed by Expertise Your End-to-End Solution

| Service Method | Description | Expected Lifespan (months) | Maintenance Frequency | Typical Cost (USD) |

|---|---|---|---|---|

| Initial Installation | Professional installation of synchronous belt systems. | 24 | N/A | 1500 |

| Regular Inspection | Periodic inspection to check for wear and alignment issues. | N/A | Every 6 months | 250 |

| Belt Replacement | Replacement of worn-out synchronous belts to maintain efficiency. | 60 | Every 2-3 years | 800 |

| Lubrication | Applying lubricant to reduce friction and wear. | N/A | Every 3 months | 100 |

| Emergency Repair | Immediate service to fix unexpected breakdowns. | N/A | As needed | Varies |

Key Steps to Choosing Polyurethane Synchronous Belt Custom Solutions, Global Reach

S

Sophia Scott

I highly value the quality of this product. The service team showed remarkable professionalism in addressing my issues.

02 July 2025

N

Noah Hill

Excellent performance! The after-sales service team displayed a level of expertise that is hard to find.

21 May 2025

Z

Zoe Edwards

This product is fantastic! The team provided quick and insightful answers to all my questions.

30 May 2025

M

Maya Ward

The quality has truly impressed me! The customer service representatives are very knowledgeable and friendly.

16 June 2025

H

Henry Parker

This item meets all of my expectations! The after-sales support was impressive and very professional.

08 June 2025

E

Elena Baker

Excellent quality and durability! The customer service was responsive and reliable.

22 May 2025