OEM Timing Belt Oil - Trusted Supplier & Exporter of Quality Automotive Parts

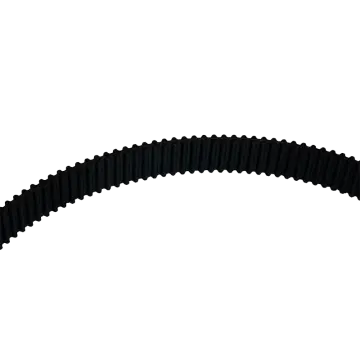

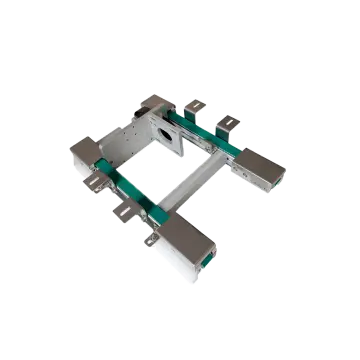

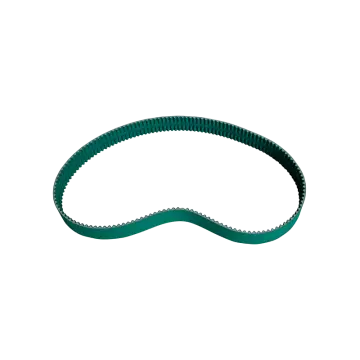

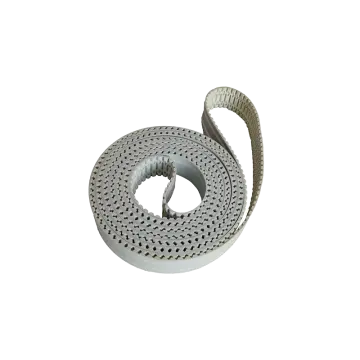

As a trusted provider of premium automotive components, we deliver superior solutions for your timing belt requirements with our specialized Oil On Timing Belt products. Our belts are engineered for exceptional performance, utilizing high-quality materials that ensure durability and dependability. Partnering with esteemed OEM manufacturers, we adhere to the highest industry standards to guarantee reliability. Ideal for manufacturers and B2B purchasers alike, our timing belts significantly improve the efficiency of machinery and vehicles. At Nantong Lanpeng Intelligent Machinery Co., Ltd., our focus is on maintaining quality and achieving customer satisfaction. Trust in our Oil On Timing Belt offerings to meet your unique needs. Contact us to learn how we can support your business.Best Practices For Oil On Timing Belt Where Service Meets Innovation Is The Best

When it comes to ensuring optimal performance in machinery, the timing belt plays a crucial role. However, oil contamination on timing belts is a common concern that can lead to reduced efficiency and potential failures. Understanding best practices for managing oil on timing belts is essential for any industrial operation looking to maintain peak performance and longevity of their equipment. One of the key strategies is to ensure proper sealing and protection around the timing belt area, preventing oil leaks from affecting the belt's integrity. Regular inspections should be conducted to identify any early signs of wear and tear, allowing for timely interventions before problems escalate. Incorporating innovative solutions, such as oil-resistant materials and advanced manufacturing techniques, can significantly extend the lifespan of timing belts in oil-prone environments. Additionally, training maintenance personnel on the significance of monitoring oil levels and the timely replacement of faulty components fosters a proactive approach to equipment management. By embracing these best practices, companies can not only enhance the performance and reliability of their machinery but also minimize operational interruptions and maintenance costs. The convergence of service and innovation is key to addressing the challenges posed by oil contamination on timing belts. By investing in advanced technology and prioritizing maintenance best practices, businesses can ensure their equipment operates seamlessly, thereby driving productivity and profitability. In an increasingly competitive global market, adopting such strategies serves as a significant advantage for companies committed to excellence in their industrial operations.

Best Practices For Oil On Timing Belt Where Service Meets Innovation Is The Best

| Practice | Description | Frequency | Benefits |

|---|---|---|---|

| Regular Inspections | Inspect the timing belt for signs of wear and oil contamination. | Every 6 months | Prevents premature failure and extends the belt's lifespan. |

| Oil Seal Checks | Ensure oil seals are functioning properly to prevent leaks that may damage the belt. | With every oil change | Minimizes risk of oil contamination on the timing belt. |

| Use Quality Oil | Select high-quality oil that meets the manufacturer’s specifications. | Every oil change | Enhances engine performance and protects the timing belt. |

| Professional Installation | Have the timing belt installed by a certified technician. | As needed | Ensures correct tension and alignment, reducing likelihood of failure. |

| Documentation | Keep records of all inspections, oil changes, and belt replacements. | Ongoing | Improves maintenance tracking and future decision making. |

How To Find The Best Oil On Timing Belt More Than a Supplier - A Partner Outperforms the Competition

M

Michael Thompson

The quality of the product exceeded my expectations. The after-sales service was prompt and the representative was exceptionally knowledgeable.

09 June 2025

B

Benjamin Martinez

The items I ordered arrived in perfect condition. The after-sales service staff were not only helpful but also very knowledgeable.

15 June 2025

A

Alexander Mitchell

A solid product with a great design. The support staff were very professional and handled my requests swiftly.

25 May 2025

S

Scarlett Flores

Absolutely love this product! The after-sales team handled my queries brilliantly, reflecting their expertise.

13 June 2025

C

Carter Harris

Fantastic product! The after-sales team was meticulous and dedicated in helping me.

23 June 2025

C

Chloe Davis

I am truly impressed with the quality. The customer service was knowledgeable and very efficient.

09 May 2025