How PU Flat Belts Deliver High Friction and Silent Power Transmission

A Pu Flat Belt offers high friction and quiet power transmission. Advanced polyurethane materials and seamless construction create a smooth, reliable experience. This belt resists oil and hydrolysis. Many industries trust it for clean, precise, and energy-saving performance. Custom features help meet special needs in demanding environments.

Key Takeaways

- PU flat belts use strong polyurethane material that resists oil, moisture, and wear, making them durable and reliable in tough environments.

- The flat belt design provides high friction and smooth power transmission while reducing noise and vibration for quieter machine operation.

- Customizable PU flat belts help industries save energy, protect delicate products, and improve efficiency across many applications.

PU Flat Belt: Unique Features and High Friction Performance

Polyurethane Material Advantages

Polyurethane gives the PU flat belt its strength and flexibility. This material stands up to tough environments. It resists oil and hydrolysis, so it lasts longer even when exposed to moisture or chemicals. Many industries choose polyurethane because it keeps its shape and performance in both hot and cold conditions.

- Polyurethane elastomers based on PTMEG, MDI, and BDO show strong hydrolysis resistance. They keep working well in wet or harsh places.

- These belts stay flexible at low temperatures. They do not crack or lose strength when it gets cold.

- Polyurethane bounces back after impacts. This helps the belt last longer and handle sudden loads.

- The material resists both sliding and hitting abrasion. This means less wear and fewer replacements.

- Low heat build-up keeps the belt from breaking down during long runs.

- Manufacturers can adjust the formula to make the belt harder, stronger, or more tear-resistant for special jobs.

A PU flat belt made with these materials offers seamless conveying without damaging materials. It supports OEM customization, so companies can get the right belt for their needs.

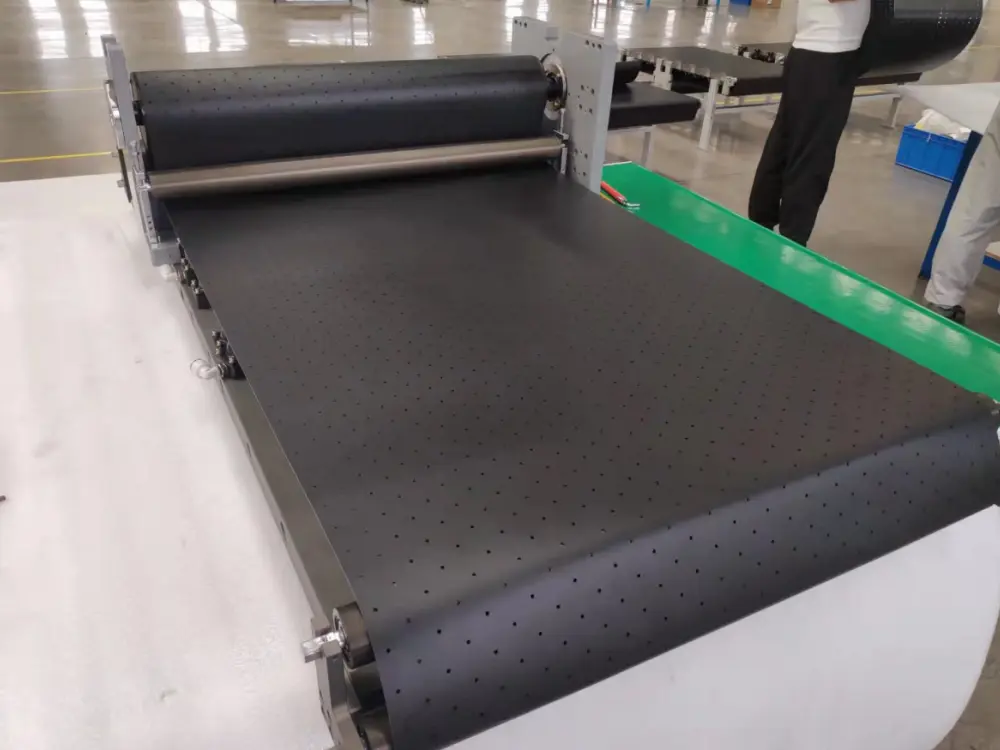

Flat Belt Design and Surface Friction

The design of a PU flat belt helps it grip surfaces and move power smoothly. The flat, grooveless shape spreads out the contact area. This reduces energy loss and keeps the belt from slipping.

- Many PU flat belts use surface covers like Polyester Canvas or Thermoplastic Polyurethane (TPU). These covers can reach a friction coefficient of up to 0.7 against polished copper.

- The belts are built to minimize slippage and maximize grip. This makes power transmission reliable.

- The flat surface also helps reduce wear. It keeps the belt running smoothly for a long time.

- PU flat belts work in a wide temperature range, from -30 to 100 degrees Celsius. They keep their grip and shape in both hot and cold places.

- Oil-resistant and heat-resistant versions are available. These keep the belt working well even in tough conditions.

- Good pulley alignment and the right belt tension help the belt track straight and avoid slipping.

- Pulley crowning, a slight curve on the pulley rim, keeps the belt centered and supports high-speed use.

Tip: Regular checks and tension adjustments help the PU flat belt keep its high friction and smooth operation.

Transmission Efficiency and Energy Savings

A PU flat belt does more than just grip well. It also saves energy and works efficiently. The belt’s design and material help reduce power loss and keep machines running smoothly.

| Measurement/Parameter | Observed Value/Effect | Implication for Energy Efficiency and Transmission Efficiency |

| Transmission efficiency | Up to 98% | Very little power is lost during operation |

| Slip and efficiency relationship | Increased slip causes ~30% efficiency decrease | Anti-slip design saves energy |

| Surface roughness reduction (Ra and Rz) | Ra decreased by ~48%, Rz decreased by ~86% | Smoother surface means less wear and better efficiency |

| Temperature stability | Operates from −30 °C to +80 °C | Works well in many environments |

| Hardness reduction after use | 10% decrease compared to new belt | Low wear, long-lasting performance |

The PU flat belt’s high friction and anti-slip properties mean less wasted energy. Machines run cooler and quieter. The belt does not need oil or grease, so it keeps production lines clean—perfect for food and electronics factories. Custom tooth structures are also available for high torque or synchronous transmission needs.

PU Flat Belt: Silent Operation and Real-World Benefits

Low Noise and Vibration Dampening

Many factories want machines that run quietly. A PU flat belt helps make this possible. The belt’s smooth surface and flexible material absorb vibrations. This means less noise during operation. Workers can talk easily on the production floor. Machines with less vibration also last longer. The belt does not need oil or grease, so it stays clean and does not create extra mess.

Some belts make a lot of noise when they move fast. The PU flat belt keeps things quiet, even at high speeds. This makes it a great choice for places like food factories or electronics plants. People working near these machines feel more comfortable. The belt’s design also helps reduce shaking. This protects both the machine and the products it moves.

Tip: Quiet machines help create a safer and more pleasant workplace. They also help companies meet noise regulations.

Seamless Conveying and Material Protection

A PU flat belt moves products smoothly from one place to another. The belt has no seams or joints, so it does not catch or damage items. This is important for industries that handle delicate goods. For example, food and electronics need gentle handling to avoid scratches or breaks.

The belt’s surface grips items just enough to keep them steady. It does not slip or slide, even when moving quickly. The oil and hydrolysis resistance of the PU flat belt means it works well in wet or oily environments. Companies can trust the belt to keep products safe and clean.

- The seamless design prevents jams and reduces downtime.

- The belt’s gentle touch protects fragile items.

- No need for extra lubrication, so there is less risk of contamination.

Many companies choose this belt for packaging, sorting, and assembly lines. They know it will not damage their products.

Industrial Applications and Customization

Factories and warehouses use PU flat belts in many ways. The belt’s strong material and flexible design fit different machines and tasks. Companies can order belts in special sizes or shapes. Some need belts with extra grip. Others want belts that can handle heavy loads or work in hot or cold places.

Here are some real-world examples:

- Automotive manufacturing plants use customized PU flat belts to move heavy car parts. These belts help speed up assembly and reduce machine downtime.

- Food and beverage companies use modular conveyors with PU flat belts. They have seen packaging speeds increase by 20%. The belts also protect food from damage.

- E-commerce fulfillment centers use adaptable roller conveyors with PU flat belts. These systems sort and deliver packages faster, making customers happier.

- Pharmaceutical factories use special PU flat belts with safety features. These belts help meet strict industry rules and improve product quality.

Polyurethane Flat Belts also work well in tough industries like mining and aggregate production. One mining company switched to polyurethane deck panels and cut screen replacement costs by 63%. They processed 12,000 tons of iron ore per hour. Aggregate producers saw a 22% increase in throughput with modular polyurethane screens. These stories show how the PU flat belt adapts to different needs and helps companies save money.

Note: Companies can ask for OEM customization. This means they get the exact belt they need for their machines and products.

A PU flat belt gives industries a smart choice for power transmission. It offers high friction, quiet operation, and long-lasting strength. Companies see smoother machines and lower costs. They enjoy clean, precise, and reliable results every day.

- High friction

- Silent running

- Durable design

FAQ

What makes a PU flat belt different from a rubber belt?

A PU flat belt uses advanced polyurethane. It resists oil and water. It runs quieter and lasts longer than most rubber belts.

Can a PU flat belt handle custom requirements?

Yes! Manufacturers offer OEM customization. They can adjust size, surface, or tooth structure to fit special machines or unique production needs.

Is a PU flat belt safe for food or electronics?

Absolutely. The belt does not need oil or grease. It keeps production lines clean and avoids contamination risks in sensitive industries.

Tip: Always check with the supplier for the best belt match for your application.