How Can Rubber Timing Belt Custom 72h Surprise You in 2025?

Key points:

- Rubber timing belt custom 72h provides ultra-fast delivery.

- LP's Digital Twin System drives speed and reliability.

Rubber Timing Belt custom 72h sets a new standard for speed in custom solutions. As shown in the table below, LP belt achieved 100% on-time delivery and response times of two hours or less for their customers, taking a customer in Guangdong as an example. LP Belt supports rapid OEM customization from their China base, offering spot direct delivery for over 1000 products. Businesses gain immediate benefits such as faster turnaround, reduced downtime, and integrated solutions with matching Belt Pulleys. Rubber Open Timing belt, PU timing belt, and PU flat belt options all support high-precision needs for automation and packaging.

| Manufacturer Region | On-time Delivery Rate | Average Response Time | Notes |

|---|---|---|---|

| Multiple Guangdong-based customers | 100% | ≤2 hours | Fast prototyping with sample turnaround ≤72 hours |

| Other customers (various) | 95.5% - 100% | ≤2 to ≤12 hours | High on-time delivery rates, rapid response times |

Key Takeaways

- Rubber timing belt custom 72h delivers fast, precise, and reliable belts within just three days, helping businesses reduce downtime and speed up production.

- Advanced materials and smart design ensure belts handle heavy loads, resist wear, and fit perfectly with matching pulleys for smooth operation.

- LP's Digital Twin System uses virtual modeling to prevent errors, improve quality, and enable real-time customization for every belt.

- Faster delivery and tailored solutions cut costs, increase agility, and reduce the need for large spare inventories in industries like automation and packaging.

- Innovations in materials, 3D printing, and smart sensors will make custom Timing Belts stronger, greener, and smarter by 2025, keeping businesses competitive.

Rubber Timing Belt Custom 72h: Ultra-Fast Customization

Key Points:

Rubber timing belt custom 72h delivers rapid, high-precision solutions. Advanced materials and engineering ensure durability and reliability. Seamless integration with matching pulleys supports efficient system performance.

High-Precision, High-Load, Long-Life Performance

Rubber timing belt custom 72h stands out for its ability to meet demanding industrial requirements. The belts use a durable elastomeric backing that protects against environmental and frictional wear. Fiberglass tensile cords provide strength and resist elongation, supporting heavy loads and frequent cycles. The nylon tooth facing creates a tough wear surface, extending service life and reducing maintenance needs. Curvilinear HTD™ tooth geometry eliminates stress concentration, allowing higher power capacity and longer belt life. These belts operate efficiently with no slippage and maintain constant driven speeds. The temperature range spans from -30°C to +80°C, making them suitable for various environments. Compliance with ISO 9001 to ensure reliability in automation, automotive, and packaging machinery.

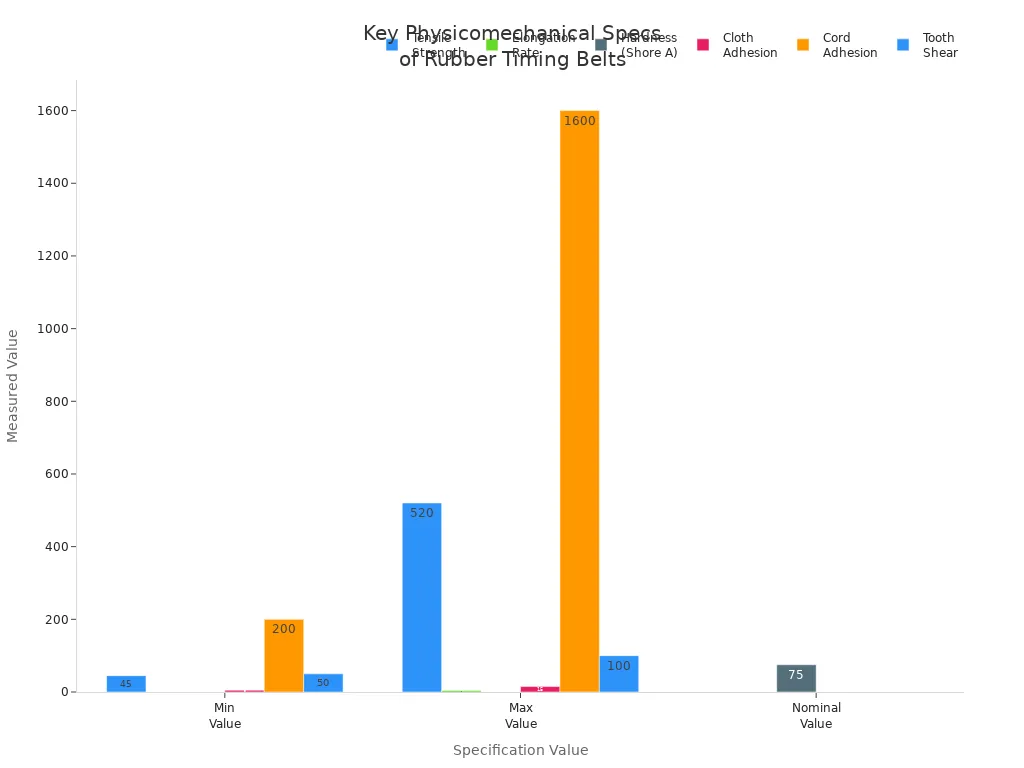

| Specification | Value/Range | Benefit |

|---|---|---|

| Tensile Strength | 45–520 N/mm | Handles high loads |

| Elongation Rate | ≤4.0% | Maintains precision |

| Hardness | Shore A 75°±5° | Resists deformation |

| Cloth Adhesion Strength | 5–15 N/mm | Durable tooth surface |

| Cord Adhesion Strength | 200–1600 N/mm | Strong belt structure |

| Tooth Shear Strength | 50–100 N/mm | Withstands heavy cycles |

| Tooth Geometry Types | Trapezoid, S-toothed, Parabolic, G/Y-toothed | Application flexibility |

| Pitch Sizes | 2.032–22.225 mm | Precise fit for various systems |

| Noise Level | Low | Quiet operation |

| Certification | ISO 9001 | Quality assurance |

How the 72-Hour Promise Works

Rubber timing belt custom 72h uses advanced digital modeling and streamlined production to deliver custom belts in just three days. The process begins with precise virtual modeling, allowing engineers to specify belt dimensions, tooth profiles, and material properties. Automated systems translate these specifications into production instructions. High-speed manufacturing lines use quality-controlled materials, such as high-strength glass fiber cords and nylon 66 cloth, to produce belts that meet strict standards. Quality assurance teams inspect each belt for accuracy and durability before shipment. This rapid workflow reduces lead time by 92%, helping businesses minimize downtime and respond quickly to changing needs.

Matching Pulleys for Seamless Integration

Seamless integration between Timing Belts And Pulleys is essential for reliable system performance. Rubber timing belt custom 72h offers matching pulleys designed to fit the exact pitch and profile of each belt. This compatibility prevents slippage and premature wear. Standard profiles include MXL, XL, L, HTD, and GT2/GT3, ensuring that belts and pulleys pair correctly for positive engagement. Metric and imperial sizes support global applications. Installation follows precise steps:

- Match the belt pitch with the pulley pitch for a snug fit.

- Use proper belt tensioners to maintain correct tension.

- Align pulley and belt using precision tools.

- Check pulley seating and orientation on the shaft.

- Adjust alignment with shims or repositioning tools.

- Follow manufacturer guidelines for installation and maintenance.

Tip: Always pair the correct belt and pulley profile to maximize system life and efficiency.

LP's Digital Twin System: The Technology Behind Speed

Key Points:

LP's Digital Twin System uses virtual modeling to eliminate manufacturing errors and inefficiencies. Real-time customization and advanced quality assurance protocols ensure every timing belt meets strict standards.

Streamlining Production with Virtual Modeling

LP's Digital Twin System transforms timing belt manufacturing by simulating every step before production begins. Engineers create a virtual model of the belt, including its geometry, material properties, and expected operating conditions. This digital approach helps identify and prevent common errors such as tooth loss, fiber separation, and teeth splitting. The system also predicts wear and damage to belt and pulley teeth, ensuring that each design can withstand friction and abrasion.

- Virtual modeling eliminates:

- Uneven load distribution

- Excessive stress on certain teeth

- Transmission errors

- Reduced efficiency due to geometrical changes

Finite element method simulations reveal how pre-tensioning affects load distribution, allowing engineers to spot critical stress points. By addressing these issues early, LP ensures that every belt delivers reliable performance and a longer lifespan. Manufacturers benefit from fewer experimental failures and less downtime.

Real-Time Customization and Quality Assurance

LP's Digital Twin System supports real-time customization, enabling engineers to adjust belt specifications instantly. The system models inspection points and sampling plans, predicting how changes will impact production capacity and product quality. Statistical process control strategies are validated through simulation, optimizing quality monitoring without slowing down manufacturing.

- Quality assurance protocols include:

- Defect pattern analysis and root cause identification

- Placement of inspection points for maximum effectiveness

- Modeling of yield rates and fallout to ensure customer commitments

- Integration of Six Sigma improvement initiatives for operational benefits

The digital twin workflow allows LP to maintain high yield rates and minimize defects. Customers receive belts that meet strict standards, with every product passing through optimized inspection and rework processes. This approach guarantees consistent quality and supports rapid delivery, setting a new benchmark for timing belt manufacturing in 2025.

92% Lead Time Reduction: Direct Impact on Your Business

Key Points:

A 92% reduction in lead time transforms how companies manage production schedules, respond to urgent needs, and control costs. Rubber timing belt custom 72h enables businesses to move from weeks-long waits to rapid, reliable delivery.

From Weeks to 72 Hours: A Case Example

Many industries once waited several weeks for custom timing belts. This delay often caused production lines to stop and increased operational costs. Rubber timing belt custom 72h changes this scenario. Now, companies receive custom belts in just three days.

Consider a packaging plant that relies on specialized automation equipment. The plant needs A Timing Belt with a unique profile and material to handle high loads and frequent cycles. In the past, the plant waited up to four weeks for a replacement. Production stopped, and the company lost revenue.

With rubber timing belt custom 72h, the plant submits its requirements online. Engineers use digital modeling to confirm the design. The manufacturing team produces the belt and matching pulleys within 72 hours. The plant receives the new belt, installs it, and resumes production almost immediately.

| Traditional Lead Time | Rubber Timing Belt Custom 72h | Result |

|---|---|---|

| 3–4 weeks | 72 hours | 92% faster delivery |

| High downtime costs | Minimal downtime | Increased productivity |

| Uncertain fit | Precision customization | Reliable operation |

This rapid turnaround supports urgent repairs and scheduled maintenance. Companies no longer need to keep large inventories of spare belts. They gain flexibility and confidence in their supply chain.

Agility, Reduced Downtime, and Cost Savings

Key Points:

Fast customization and delivery improve agility, reduce downtime, and lower costs. Businesses benefit from tailored solutions and advanced support.

Downtime remains a major challenge for industries using rubber timing belts. Several factors contribute to lost production time:

- Belts must fit specific OEM equipment and unique machinery setups. Delays occur if the right belt is not available.

- Harsh operating conditions, such as impact loads, dust, moisture, and temperature extremes, can cause belt failures.

- Improper fit or material selection increases the risk of breakdowns and unplanned stops.

- Waiting for replacement belts often means extended machine downtime.

Rubber timing belt custom 72h addresses these issues with rapid, precise customization. Companies specify length, width, tooth profile, and special coatings to match their exact needs. This feature reduces downtime and keeps production moving.

Quality assurance plays a key role. Reputable manufacturers use material traceability and batch testing. Each belt meets strict standards, ensuring reliable performance in tough environments.

After-sales support adds another layer of protection. Technical assistance, warranty coverage, and fast replacement services help companies resolve issues quickly.

Tip:

Customization options—such as cleats, coatings, and special materials—ensure belts fit unique machinery. This reduces the risk of improper fit and associated downtime.

The result is clear:

- Faster response to urgent needs

- Less time lost to equipment failures

- Lower inventory and storage costs

- Improved operational efficiency

Rubber timing belt custom 72h gives businesses the agility to adapt, the reliability to maintain uptime, and the cost savings to stay competitive in 2025.

Rubber Timing Belt Custom 72h in 2025: Innovations to Watch

Key Points:

2025 will bring new technologies, smarter materials, and expanded applications for custom timing belts. Companies will see faster production, better performance, and more sustainable solutions.

Upcoming Advances and Scalability

Manufacturers expect several breakthroughs in custom timing belt production by 2025.

- 3D printing will allow the creation of complex belt shapes that traditional methods cannot achieve. This technology will speed up prototyping and enable lighter, more efficient belts.

- New materials, including advanced thermoplastics, polyurethane, and hybrid composites, will improve belt strength, durability, and eco-friendliness.

- Collaborative research among companies and universities will drive new manufacturing processes and material blends.

- Preventive maintenance tools, such as laser alignment calibration and vibration sensors, will become more precise. These tools will help extend belt life and keep machines running smoothly.

Scalability remains a focus as demand grows.

- Sourcing critical components like chipsets for drive systems can be challenging. Companies look for alternative solutions to avoid delays.

- Modular conveyor designs and digital configuration tools help factories expand quickly without major disruptions.

- Manufacturers use rapid design and testing methods to adapt systems within existing spaces, reducing downtime and maximizing investment.

New Surprises and Industry Trends

Key Points:

The rubber timing belt custom 72h market will see smarter, greener, and more connected products. Industry trends point to greater automation, data-driven maintenance, and global growth.

Industry leaders introduce new features that surprise professionals each year.

- Anti-static coatings, high-heat resistance, and longer lifespan belts are becoming standard.

- Smart belts with embedded sensors allow real-time monitoring and predictive maintenance, reducing unexpected failures.

- Polymer engineering brings aramid fiber reinforcement and EPDM compounds, making belts tougher and longer-lasting.

- Sustainable rubber compounds and bio-based materials support eco-friendly manufacturing and compliance with regulations.

Automation and energy efficiency drive demand for custom-engineered belts in robotics, medical devices, and electric vehicles. Digital tools like CAD modeling and simulation help create precise, application-specific solutions. The rubber timing belt custom 72h service stands out by delivering these innovations rapidly, helping businesses stay ahead in a fast-changing market.

Key Points:

Rubber timing belt custom 72h delivers unmatched speed, reliability, and customization for modern industries. LP's Digital Twin System drives efficiency and flexibility, helping companies adapt quickly.

Industry analysts highlight several long-term benefits:

- Digitization and innovation cycles accelerate product development.

- Economic diversification boosts demand for tailored solutions.

- Customer-centric trends increase personalization and convenience.

- Sustainability goals encourage energy-efficient designs.

| Long-term Impact | Supporting Factors |

|---|---|

| Improved Efficiency | Advanced materials and automation |

| Market Expansion | Growth in emerging markets and aftermarket demand |

| Competitive Advantage | Rapid customization and regulatory compliance |

| Innovation Leadership | R&D and smart manufacturing |

| Sustainability Support | Durable, eco-friendly products |

FAQ

Key Points:

This FAQ addresses common questions about rubber timing belt custom 72h, including customization, delivery, compatibility, and support.

What industries benefit most from rubber timing belt custom 72h?

Automation, automotive, and packaging industries gain the most. These sectors require high-precision, durable belts for reliable performance. Fast delivery helps reduce downtime and keeps production lines running smoothly.

How does the 72-hour customization process work?

Engineers use digital modeling to design the belt. The factory produces the belt using advanced materials and strict quality checks. The team ships the finished product within 72 hours.

Can customers order matching pulleys with their belts?

Yes. Customers can request matching pulleys designed for their specific belt profile. This ensures seamless integration and optimal system performance.

What materials are used in LP’s rubber timing belts?

LP uses high-strength glass fiber cords and nylon 66 high-elastic cloth. These materials provide strength, flexibility, and long service life. The belts resist wear and operate quietly.

Is technical support available after purchase?

Yes. LP offers technical support, installation guidance, and warranty services. Customers receive help with product selection, installation, and troubleshooting.