Essential Factors to Evaluate When Selecting Aluminum Timing Pulleys

Selecting the appropriate aluminum timing pulleys is essential for any industrial automation upgrades. The right choice can improve precision and accuracy, ensuring that the timing belt pulleys mesh seamlessly. This decision also enhances energy efficiency, decreases friction, and lowers maintenance requirements. Ultimately, these elements play a vital role in enhancing overall system performance and reliability.

Key Takeaways

- Understand power requirements. Choose pulleys that can handle the necessary torque to ensure reliability and longevity.

- Consider speed limits. Select pulleys that match the maximum speed of your belt type to enhance efficiency and reduce wear.

- Evaluate the transmission ratio. Calculate the ratio based on your application needs to optimize power and speed transfer.

Power Requirements of Aluminum Timing Pulleys

When selecting Aluminum Timing Pulleys, understanding power requirements is crucial. The power needed directly influences the size and material of the pulley. For instance, machines that generate higher torque require stronger pulleys. If the pulleys can't handle the power, they may wear out quickly or even fail.

Here are some key points to consider regarding power requirements:

- Torque Needs: Higher torque machines demand robust pulleys. Choosing a pulley that can withstand the necessary torque ensures longevity and reliability.

- Load Distribution: Even load distribution across the pulley is essential. This balance helps prevent premature wear and tear, extending the life of the system.

- RPM Support: The pulley must support the required RPM for optimal speed and efficiency. If the pulley can't keep up, it can lead to performance issues.

By evaluating these factors, you can make an informed decision when selecting aluminum timing pulleys. This careful consideration will help ensure that your system operates smoothly and efficiently.

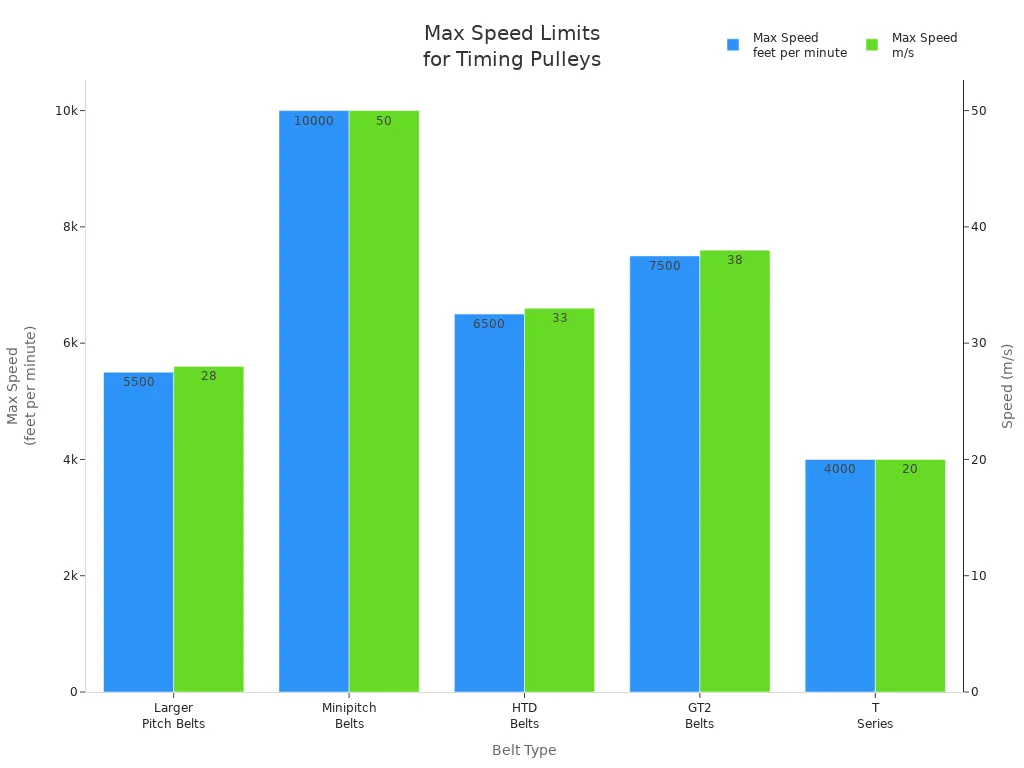

Speed Considerations for Aluminum Timing Pulleys

When selecting aluminum timing pulleys, speed considerations play a vital role in ensuring optimal performance. The maximum speed at which a pulley can operate directly impacts the efficiency of your system. If the speed exceeds the recommended limits, it can lead to premature wear or even failure of the pulleys.

Here are some key points to keep in mind regarding speed:

- Belt Type Matters: Different belt types have varying maximum speed limits. Understanding these limits helps you choose the right pulley for your application.

- Efficiency and Performance: Operating within the recommended speed range enhances overall system efficiency. It reduces energy consumption and minimizes wear on components.

To give you a clearer picture, here’s a table showing the maximum speed limits for various belt types:

| Belt Type | Maximum Speed (feet per minute) | Maximum Speed (m/s) |

|---|---|---|

| Larger Pitch Belts | 5500 | 28 |

| Minipitch Belts | 10000 | 50 |

| Htd Belts | 6500 | 33 |

| GT2 Belts | 7500 | 38 |

| T Series | 4000 | 20 |

By considering these speed factors, you can ensure that your aluminum timing pulleys operate efficiently and effectively. This careful evaluation will help you avoid potential issues and enhance the longevity of your system.

Transmission Ratio in Aluminum Timing Pulleys

When selecting aluminum timing pulleys, understanding the transmission ratio is key. The transmission ratio determines how power and speed transfer between the pulleys and the belt. It plays a significant role in the overall performance of your system.

Here are some important points to consider:

-

Definition: The transmission ratio is the ratio of the number of teeth on the driving pulley to the number of teeth on the driven pulley. This ratio affects speed and torque.

-

Speed Control: A higher transmission ratio means the driven pulley will rotate slower than the driving pulley. This can be useful for applications requiring more torque but less speed. Conversely, a lower ratio allows for higher speeds but less torque.

-

Application Suitability: Different applications require different transmission ratios. For instance, if a machine needs to lift heavy loads, a higher ratio is beneficial. On the other hand, if speed is the priority, a lower ratio works better.

Tip: Always calculate the required transmission ratio based on your specific application needs. This ensures that your aluminum timing pulleys operate efficiently and effectively.

By evaluating the transmission ratio, you can optimize your system's performance. This careful consideration helps ensure that your aluminum timing pulleys meet the demands of your application.

Shaft Diameter for Aluminum Timing Pulleys

When it comes to aluminum timing pulleys, the shaft diameter plays a crucial role in ensuring optimal performance. A proper fit between the pulley and the shaft can significantly affect the efficiency and safety of your system. If the shaft diameter doesn’t match the pulley, it can lead to misalignment, increased wear, and even failure of the assembly.

Here are some key points to consider regarding shaft diameter:

-

Compatibility: Always check the bore diameter of the pulley. A mismatch can cause issues. For example, a bore diameter of 10mm with an adjustable feature allows for fixed 8mm shaft mounting. This flexibility helps accommodate various shaft sizes.

-

Customization Options: Many manufacturers offer customization for shaft sizes. This means you can find the perfect fit for your specific application. Customization ensures that your aluminum timing pulleys work seamlessly with your machinery.

-

Performance and Safety: A well-fitted pulley reduces vibrations and enhances stability. This stability is vital for maintaining the longevity of your equipment.

Tip: Always consult the specifications of your machinery to determine the correct shaft diameter. This simple step can save you from costly repairs down the line.

By paying attention to shaft diameter, you can enhance the performance and safety of your aluminum timing pulleys. This careful evaluation ensures that your system runs smoothly and efficiently.

Center Distance in Aluminum Timing Pulleys

Center distance is a critical factor when selecting aluminum timing pulleys. It refers to the distance between the centers of two pulleys in a belt drive system. Getting this measurement right ensures proper belt tension and alignment, which are vital for smooth operation.

To calculate the center distance, you can use the following formula:

- C = (L - π(D + d)) / 2

- Here, L is the belt length, D is the diameter of the larger pulley, and d is the diameter of the smaller pulley.

This formula considers the belt length on both the top and bottom of the pulleys. It also accounts for the belt length wrapped around the pulleys’ circumference.

Accurate center distances prevent excessive belt tension. High tension can lead to mechanical failures, such as bending of shafts and reduced bearing life. On the flip side, low tension can cause non-uniform tooth engagement, leading to belt ratcheting. Variations in center distance can cause significant fluctuations in belt tension, potentially leading to a threefold variation at installation.

For convenience, you can also use online tools like the Center Distance Calculator to find the exact measurement. This approach saves time and ensures accuracy.

Tip: Always double-check your calculations to avoid costly mistakes. Proper center distance enhances the performance and longevity of your aluminum timing pulleys.

In summary, five key factors play a crucial role in selecting aluminum timing pulleys: power requirements, speed considerations, transmission ratio, shaft diameter, and center distance. Careful evaluation of these elements helps avoid common mistakes, such as assuming alL Pulleys are the same or ignoring belt type compatibility.

Tip: Always consult with experts to ensure you make the best choice for your specific application. They can provide insights on matching Belts And Pulleys, using tensioners, and considering custom solutions for unique needs.

By taking these steps, you can enhance the performance and longevity of your systems.

FAQ

What materials are aluminum timing pulleys made from?

Aluminum timing pulleys typically use high-grade aluminum alloys. These materials provide strength, durability, and resistance to wear.

How do I know the right size pulley to choose?

To find the right size, consider your machine's specifications, including shaft diameter and center distance. Always consult the manufacturer's guidelines.

Can I customize aluminum timing pulleys?

Yes! Many manufacturers offer customization options for size and specific needs, such as quiet operation or corrosion resistance. Always inquire about available options.