Industry News

How High Torque Timing Pulleys Enhance Performance and Cut Costs?

High-torque Timing Pulleys enhance packaging automation by reducing energy costs and improving efficiency through minimized friction and better load handling

Aluminum Timing Pulleys Boost EV Manufacturing Efficiency

Lightweight Aluminum Timing Pulleys cut vehicle weight, boost efficiency, and extend EV range while reducing energy use in electric vehicle manufacturing

Selecting the Right Timing Pulley Tooth Profile

Select the ideal timing pulley tooth profile for Synchronous Pulleys to boost machine efficiency, reduce wear, and ensure precise, reliable power transmission.,

5 Common Causes of Timing Belt Pulley Failure and How to Prevent Them

Timing belt pulley failure often results from wear, misalignment, tension issues, contamination, or poor parts. Prevent breakdowns with proper maintenance.

How Rubber Timing Belts Outperform in Robotics & Semiconductors?

Rubber Timing Belts in 2025 offer unmatched precision, durability, and cleanroom compatibility for robotics and semiconductors, surpassing older drive systems.

How Can Rubber Timing Belt Custom 72h Surprise You in 2025?

Rubber timing belt custom 72h slashes lead time by 92%, boosting uptime and reliability for manufacturers with LP's Digital Twin System

Why Choose Customized Synchronous Pulleys for High-Performance Applications

Customized synchronous pulleys help machines work better. They give smooth and steady power where it matters most. Each synchronous pulley matches the machine’s needs. This means less downtime and more reliable performance. High-performance equipment keeps running strong, even in tough conditions.

How PU Flat Belts Deliver High Friction and Silent Power Transmission

A PU flat belt offers high friction and quiet power transmission. Advanced polyurethane materials and seamless construction create a smooth, reliable experience. This belt resists oil and hydrolysis. Many industries trust it for clean, precise, and energy-saving performance. Custom features help meet special needs in demanding environments.

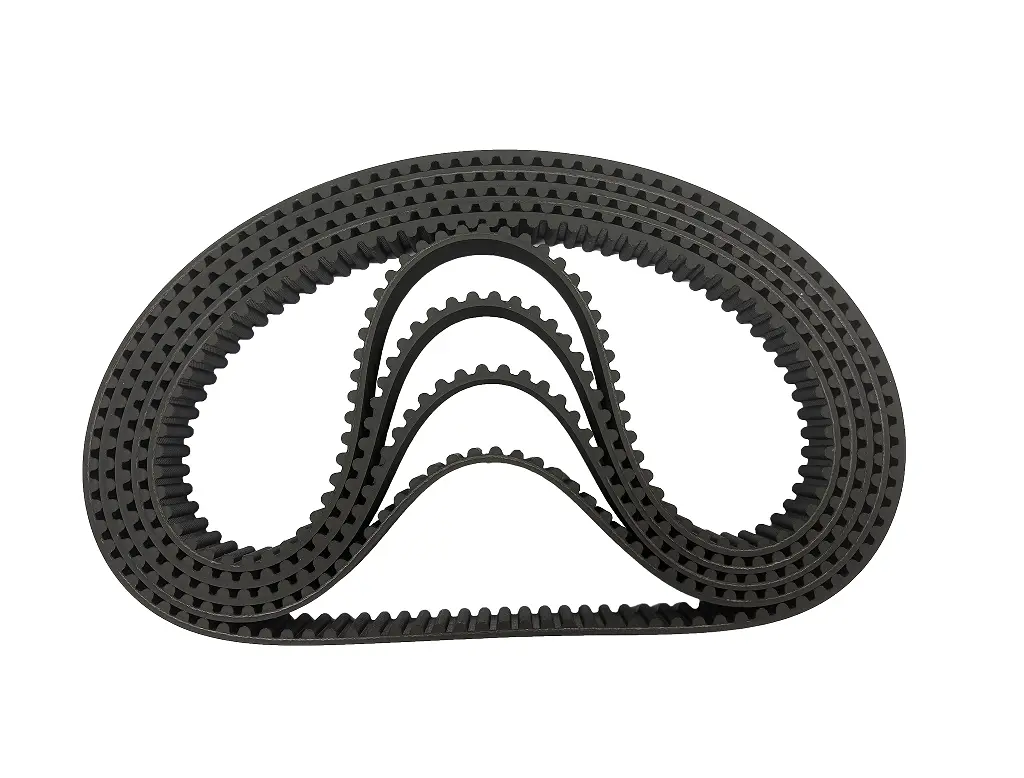

Key Advances in Rubber Double-Sided Synchronous Belts

Rubber double-sided synchronous belt technology keeps moving forward. Engineers use high-strength glass fiber cords and new rubber compounds to boost performance. Recent designs, like the LP Rubber Double-Sided Tooth Synchronous Belt, offer a 50% increase in load capacity and work well in compact, high-precision spaces such as robotics and automation.