Leave Your Message

-

Phone

-

E-mail

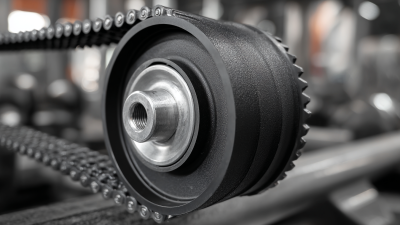

Understanding the various types of V Belt Pulleys is essential for anyone involved in machinery or mechanical engineering. These components play a vital role in power transmission. Their design greatly influences performance and efficiency.

V Belt Pulleys come in multiple shapes and sizes, with each type serving a specific purpose. Some are simple, others more complex. The right choice can improve system reliability. However, selecting a pulley isn't always straightforward. Often, misunderstandings arise regarding their applications and limitations.

Many users overlook key details. This can lead to improper installations or poor performance. It's crucial to recognize that not every pulley suits every application. Knowledge of the top types available can make a significant difference. In this guide, we will explore the most important V Belt Pulley types you should know. Each type has unique traits and functions, making them suitable for specific scenarios.

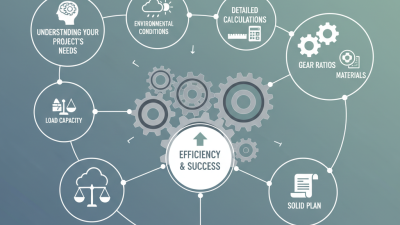

When it comes to V-belt pulleys, understanding their types can revolutionize mechanical systems. The versatility of V-belt pulleys makes them indispensable in numerous applications, from automotive engines to industrial machinery. According to recent industry reports, nearly 70% of mechanical failures in equipment are linked to improper pulley selection.

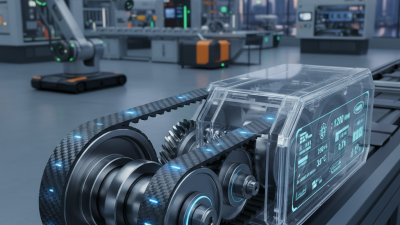

There are primarily two key types of V-belt pulleys:

Single pulleys are mainly used for lower power applications. Double pulleys can handle higher loads and improve transmission efficiency. Interestingly, reports indicate that using the correct pulley type can enhance system performance by up to 30%. This highlights the need for careful selection based on specific needs.

Another important factor is material choice. Common materials include aluminum, cast iron, and plastic. Each offers unique benefits and potential drawbacks. For example, while aluminum is lightweight, it can wear faster than cast iron under high stress. Aspects like these often go overlooked, leading to mechanical inefficiencies. Regular assessments are vital. Understanding these details can make all the difference in achieving optimal performance.

V-belt pulleys play a vital role in the world of power transmission. They connect various components within a machine to transfer mechanical energy. Understanding their functionality is essential for optimal performance and efficiency. These pulleys vary in design, affecting their effectiveness for specific tasks.

A common type is the groove pulley. Its design helps grip the V-belt securely, reducing slippage. This ensures smooth operation in machinery, which is crucial for productivity. Another is the idler pulley. It helps maintain proper tension in the belt system. Without proper tension, the system may fail or underperform.

Maintenance of these pulleys is often overlooked. Dust and debris can accumulate, affecting performance. Regular checks are necessary to avoid unexpected breakdowns. Over time, wear and tear can occur, leading to inefficiencies. A worn pulley may slip or break, causing delays. Understanding these aspects can lead to better decision-making in equipment management.

This bar chart represents the usage frequency of various types of V belt pulleys in power transmission systems. The data reflects how commonly each type of pulley is utilized in different applications.

When comparing standard and specialty V belt pulleys, important differences emerge. Standard pulleys are widely used and easily accessible. They come in various sizes and materials. Their simplicity makes them a go-to choice for many applications. However, they might not always meet specific demands. In some cases, they wear out quickly under heavy loads.

Specialty pulleys, on the other hand, cater to unique situations. They boast features like lightweight designs or advanced materials. This specialization can enhance efficiency in particular applications. Yet, they may be harder to find and more expensive. Not every option fits every machine. Users might struggle to decide which type suits their needs best.

Choosing the right pulley is crucial. Analysis of load requirements and application specifics helps illuminate the best choice. While standard pulleys offer convenience, specialty options can provide efficacy. Each has its merits and drawbacks. Understanding these differences is vital for optimal performance and longevity.

When selecting materials for V belt pulleys, performance is key. The choice directly affects durability, efficiency, and overall functionality. Common materials include metals, plastics, and composites. Each comes with unique benefits and drawbacks. For instance, metal pulleys are renowned for their strength. Yet, they can be heavy, impacting speed. Plastic pulleys weigh less, but may wear out faster.

Consider the operating environment as well. Temperature and humidity play significant roles. In high-heat conditions, some plastics may warp, while metals might withstand the heat but corrode. In these cases, a composite material may offer the best of both worlds. However, composites can be costlier and may require more complex manufacturing processes.

It's also important to assess the load and speed requirements. High-speed applications demand materials that can handle stress without deforming. Conversely, lower-speed operations might allow for less robust materials. Ignoring these factors can lead to premature failure, forcing a reconsideration of initial choices. Potential for mistakes exists, but learning from them can lead to better material selections in future designs.

| Pulley Type | Material | Typical Applications | Impact on Performance |

|---|---|---|---|

| Standard V Pulley | Cast Iron | Industrial Machinery | Good strength and durability |

| Poly-V Pulley | Plastic | Automotive Applications | High efficiency and lightweight |

| Timing Pulley | Aluminum | Robotics and Automation | Precise timing and minimal slip |

| Adjustable Pulley | Steel | Construction Equipment | Versatile tension adjustment |

| Double Groove Pulley | Cast Aluminum | Heavy Machinery | Increased load distribution |

| Sheave Pulley | Nylon | Elevator Systems | Lightweight and corrosion-resistant |

| Flat Belt Pulley | Rubber | Textile Machinery | Good friction and torque transfer |

| Variable Diameter Pulley | Composite Material | Fan Drives | Adjustable speed and torque |

| Torque Converter Pulley | Metal Alloy | Vehicle Transmissions | Smooth power transmission |

| Idler Pulley | Steel or Plastic | Belt Tensioning | Enhances belt life and efficiency |

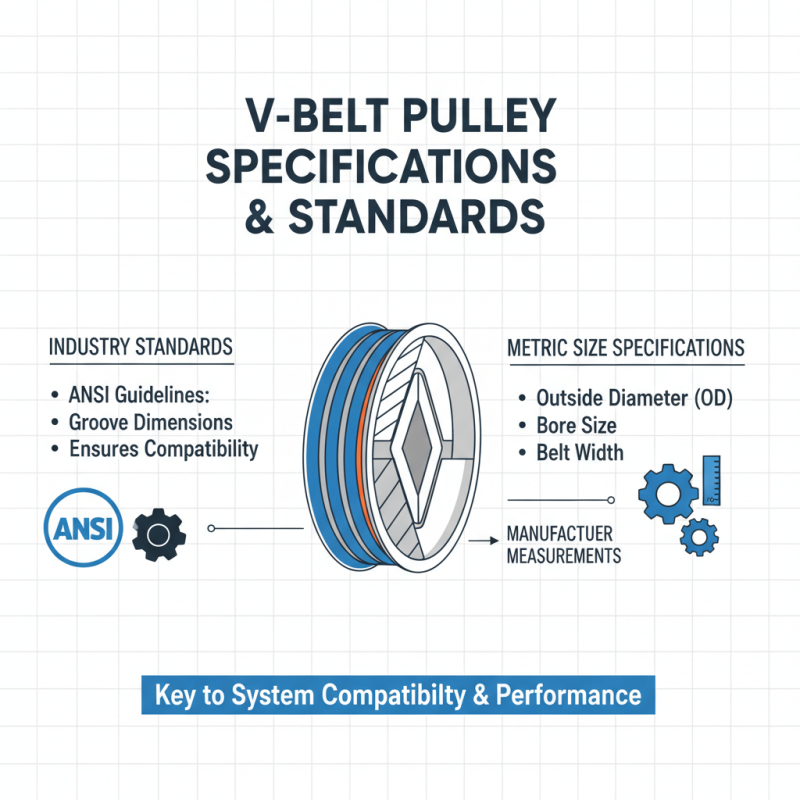

When considering V belt pulley specifications, industry standards play a crucial role. For example, the American National Standards Institute (ANSI) provides guidelines on groove dimensions. These standards ensure compatibility across various systems. V belt pulleys generally follow the metric system for size specifications. Common metrics include outside diameter, bore size, and belt width. Manufacturers often cite these measurements to meet customer needs.

Key metrics for evaluating V belt pulleys include the pitch diameter and the groove design. The pitch diameter directly affects the speed ratio between pulleys. According to industry reports, using the correct pitch diameter can improve efficiency by up to 20%. Additionally, the groove design affects belt life. For instance, a deeper groove can reduce slippage and increase traction. However, not all designs suit every application. Compatibility must be assessed based on operational requirements.

A common mistake is ignoring environmental factors. Temperature and humidity can impact pulley performance. High temperatures can warp materials, causing misalignment. Even small misalignments can lead to significant operational issues. Research indicates that about 15% of pulley failures result from improper alignment. Understanding these metrics and standards is essential for selecting the right pulleys. Overall, proper attention to detail may prevent costly downtime.