Leave Your Message

-

Phone

-

E-mail

Flat Timing Belts are crucial components in various machines and systems. Their role is often underestimated, yet they significantly impact performance and efficiency. In 2026, selecting the right flat timing belt is more important than ever. With advancements in technology, options have expanded greatly.

Choosing the best flat timing belt requires careful consideration of materials, design, and application. High-quality belts can reduce wear and improve productivity. However, not every belt will meet your specific needs. It can be challenging to find the perfect match.

Understanding the significance of flat timing belts will help in making informed decisions. They play a vital role in reducing friction and enhancing movement in machines. Investing time in research now could prevent costly breakdowns later. A lack of attention here can lead to unexpected problems down the road.

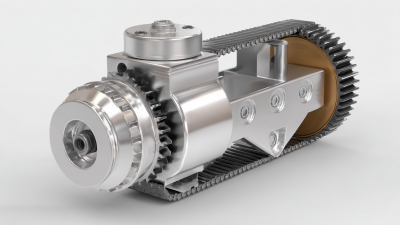

Flat timing belts are essential components in modern engineering applications. They offer precise synchronization between moving parts. This precision is crucial for machinery in various industries. It ensures that processes run smoothly without delays. Engineers often overlook the significance of these belts. However, their role in enhancing efficiency cannot be ignored.

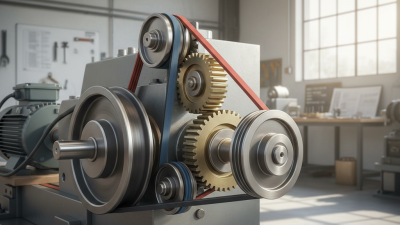

The construction of flat timing belts is quite straightforward. They are typically made from durable materials with precise dimensions. This simplicity contributes to their effectiveness. Engineers must pay attention to the selection of these belts to match specific performance needs. In some cases, mismatches can lead to mechanical failures, which are costly. It's important to evaluate the operational conditions for best results.

Using flat timing belts can be a game-changer. They reduce slippage and improve energy transmission. Nevertheless, it’s essential to regularly check their condition. Worn or damaged belts can compromise performance. This requires a proactive approach to maintenance. Engineers need to think critically about their use to ensure the longevity of equipment.

In 2026, the demand for flat timing belts will see a significant surge. This is driven by the increasing automation in various industries. Research indicates a projected growth rate of 5.7% in the timing belt market annually. The emphasis is on durability, flexibility, and efficiency.

Key characteristics of top flat timing belts include material composition, tensile strength, and design features. The best options often use high-quality synthetic elastomers. These materials enhance temperature resistance and reduce wear. Additionally, belts with reinforced fibers exhibit higher tensile strength. This leads to lower maintenance costs, making them a smart investment.

Moreover, proper sizing and specifications matter. Belts should align with the machinery to avoid slippage. Data suggests that a mismatched belt can result in a 30% efficiency loss. Observations indicate many manufacturers overlook these details. Neglecting proper installation can lead to premature failures. Understanding these characteristics will help industries choose the right belts for optimal performance in 2026.

The flat timing belt market is projected to grow significantly by 2026. This growth is primarily driven by advancements in manufacturing technologies. Industries are increasingly adopting these belts due to their efficiency and reliability. Many businesses are looking for ways to optimize their operations. Flat timing belts are becoming a preferred choice for many applications.

Current trends indicate a rising demand for custom solutions. Companies seek belts that can handle specific load requirements. These belts offer flexibility and durability in various environments. However, there are challenges. Some manufacturers struggle to keep up with the rapid advancements in materials. This can impact the quality and performance of their products.

Sustainability is also becoming a critical factor. Many industries are exploring eco-friendly materials for flat timing belts. The transition can be slow and costly. Companies need to reflect on their production processes. Adapting to these trends is essential for long-term success. The dynamics of the market will continue to evolve in the coming years. It's crucial for businesses to stay agile in this competitive landscape.

| Year | Market Size (Million $) | Growth Rate (%) | Key Applications | Material Type |

|---|---|---|---|---|

| 2023 | 450 | 5.0 | Automotive, Industrial Machinery | Polyurethane, Rubber |

| 2024 | 470 | 4.4 | Textile, Food Processing | Nitrile, Polyethylene |

| 2025 | 490 | 4.3 | Packaging, Printing | PVC, PVC Blend |

| 2026 | 510 | 4.1 | Electronics, HVAC | Silicone, High-Performance Rubber |

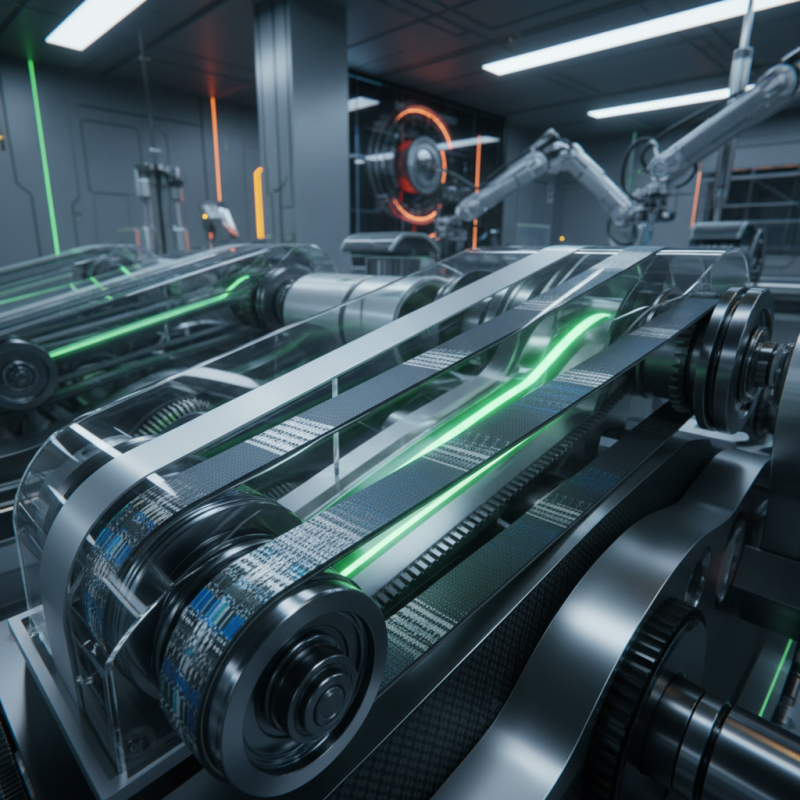

Flat timing belts have become essential in various industries. In manufacturing, they keep machinery operating smoothly. These belts drive systems in conveyors, packaging, and production lines. Their unique design reduces friction and wear. This efficiency can lead to lower operational costs.

In automotive applications, flat timing belts play a significant role. They synchronize engine components, ensuring optimal performance. This precision prevents issues that can result from engine misalignment. However, improper installation or wear can lead to failures. Regular maintenance is crucial to avoid costly repairs.

The use of flat timing belts is also growing in robotics. Their ability to handle varying loads makes them ideal for automated systems. Yet, they may not be suitable for all environments. A dusty or contaminated setting can hinder their performance. Understanding these limitations is vital for effective use.

When evaluating timing belt efficiency, performance metrics are critical. These metrics provide insight into how well a belt transfers power. A key factor is the material composition. High-quality materials resist wear and ensure durability. Material choices impact both friction and heat resistance, which can vary significantly.

Durability is another essential aspect. Even the most efficient belt can fail if it cannot withstand stress. Over time, degradation occurs due to heat and mechanical stress. Regularly checking for signs of wear can prevent sudden failures. Tracking performance metrics helps identify when a replacement is necessary.

Moreover, the installation process can influence performance. Incorrect installation might lead to misalignment, increasing stress on the belt. Monitoring the tension can also play a role in its longevity. These nuances often get overlooked. Yet, they are crucial for achieving optimal performance in applications. Understanding these factors can lead to more informed decisions and longer-lasting equipment.