Leave Your Message

-

Phone

-

E-mail

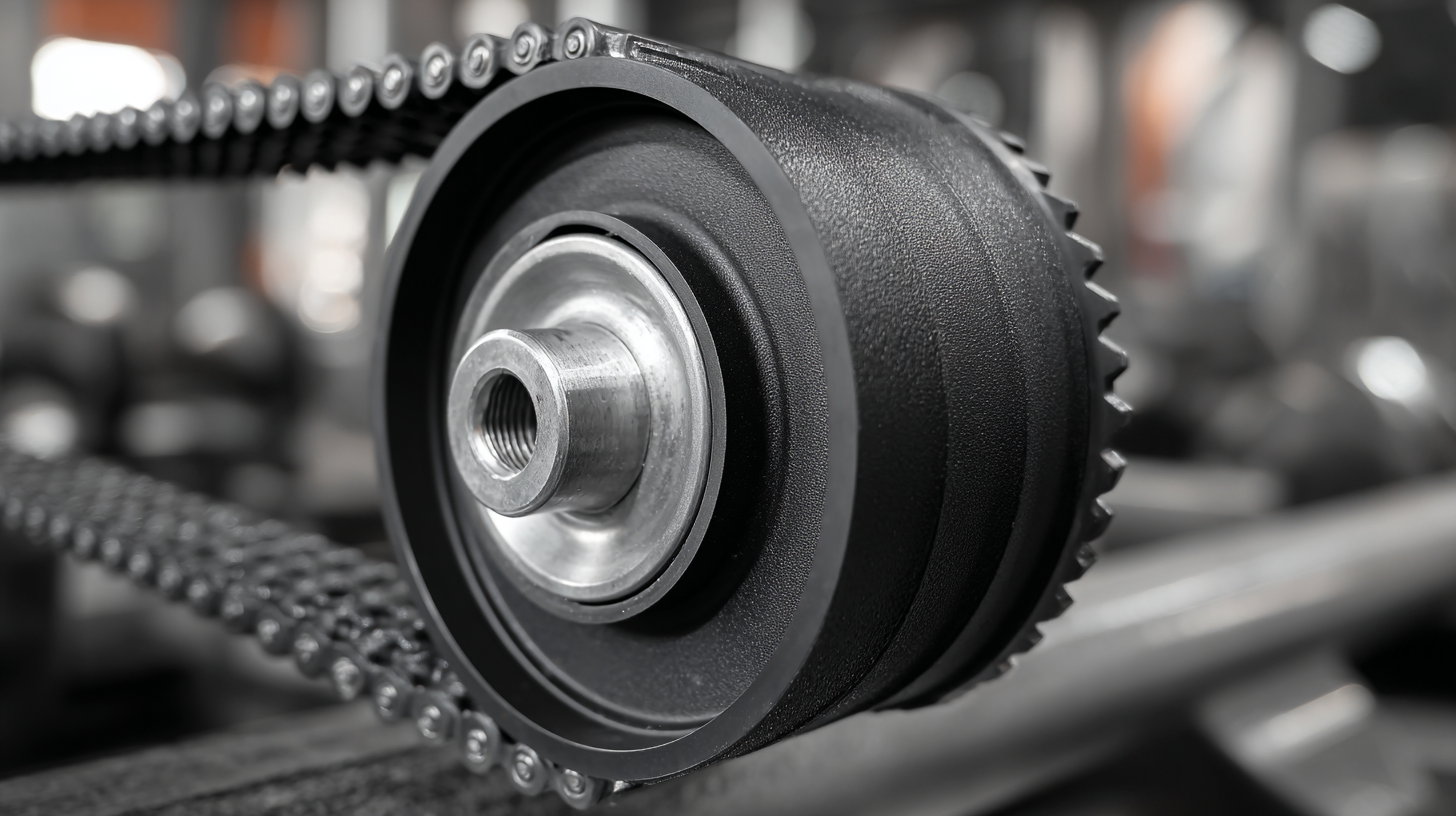

As industries continue to evolve, the demand for reliable and efficient mechanical components is more critical than ever. Among these components, the V Belt Pulley has emerged as a key player in enhancing performance and durability across various applications. According to mechanical engineering expert Dr. James McAllister, "The right V Belt Pulley can significantly reduce wear and tear while optimizing power transmission in machinery." This underscores the importance of selecting the highest quality V Belt Pulleys available in the market.

In 2025, we will witness a range of innovative V Belt Pulley designs that promise to push the boundaries of performance. The advancements in materials and engineering techniques ensure not only enhanced durability but also improved efficiency, making it essential for manufacturers and engineers to keep their eyes on the best choices. Choosing the right V Belt Pulley can drastically impact operational costs and machine longevity, making it a topic of vital interest within the industry.

In this article, we will explore the top five V Belt Pulleys of 2025, analyzing their unique features and advantages. By focusing on performance and durability, we aim to provide insights that will help professionals make informed decisions, ensuring their machinery runs smoothly and efficiently in the years to come.

When selecting V belt pulleys in 2025, there are several key considerations to keep in mind to ensure optimal performance and longevity. Firstly, the material used in manufacturing the pulley plays a crucial role in its durability. Look for pulleys made from high-quality metals or composites that can withstand wear and environmental factors. Additionally, consider the design of the pulley; options with a precise fit and minimized runout can significantly enhance efficiency and reduce vibration, which is vital for maintaining the integrity of the system over time.

Tips: Always check the specifications for compatibility with your existing V belts and machines. A proper match not only improves performance but also extends the lifespan of both the pulleys and the belts. Additionally, regular maintenance is essential. Inspect pulleys for signs of wear or misalignment frequently to catch potential issues before they lead to costly downtime.

Another important factor is the size and speed rating of the pulleys. Ensure that the selected pulley matches the operational specifications required for your application. Utilizing the correct diameters will optimize the torque transmission and speed ratios, which can enhance overall system performance. Materials with superior corrosion resistance should also be prioritized, especially in demanding environments, to prevent degradation and maintain function over time.

When selecting V belt pulleys for optimal performance, the choice of material is crucial. Many manufacturers produce pulleys from a variety of materials, each offering distinct advantages in terms of durability and resistance to wear and tear.

For instance, aluminum pulleys are lightweight and provide excellent strength, making them ideal for high-speed applications. Their resistance to corrosion ensures that they maintain performance even in harsh environments.

On the other hand, cast iron pulleys are favored for their robustness and ability to absorb vibrations, which can enhance operational stability. They typically have a longer lifespan than their aluminum counterparts but are heavier, which may affect the overall efficiency of the system.

Additionally, newer composite materials are emerging, promising a blend of lightweight and high strength, suitable for advanced applications where reducing weight without sacrificing performance is essential.

Understanding these material properties is crucial for making informed decisions that enhance both the performance and longevity of V belt systems.

Evaluating V belt pulleys requires a systematic approach that hinges on several key performance metrics. First and foremost, material quality is critical; pulleys made from high-strength alloys or composites tend to show superior durability under stress, which is essential for prolonged usage in demanding applications. Additionally, assessing the surface finish can reveal potential friction characteristics, as smoother surfaces minimize wear and contribute to overall efficiency.

Another vital metric is the pulley’s load capacity. It is essential to match the pulley with the specifications of the V belt and the application requirements. Checking compatibility involves examining not only the dimensions but also the rated load and RPM limits. Furthermore, vibration and noise levels during operation should be monitored, as excessive vibrations can indicate misalignment or imbalance, which adversely affects performance and longevity. By systematically analyzing these factors, users can make informed decisions about the best V belt pulleys to enhance overall system efficiency and reliability.

In the evolving landscape of the V belt pulley market, certain brands stand out for their commitment to performance and durability. Industry leaders have consistently pushed the envelope in design and materials, ensuring that their products not only meet but exceed user expectations. Brands like Gates, Continental, and Bando have earned a strong reputation for providing high-quality V belt pulleys that are engineered to withstand rigorous use and environmental challenges.

Additionally, newer entrants such as Optibelt and SKF are gaining traction by innovating with advanced manufacturing techniques and sustainable materials. These companies are not only focused on enhancing the lifespan and efficiency of their products but also on minimizing their environmental footprint. As consumers increasingly prioritize both performance and sustainability, these emerging brands are well-positioned to capture market share and meet the demands of modern users seeking reliable and eco-friendly solutions.

As we move towards 2025, the design and technology of V belt pulleys are poised for significant advancements. One of the key trends is the integration of advanced materials that enhance both durability and performance. Manufacturers are increasingly turning to composites and specialized alloys, which not only reduce weight but also provide better resistance to wear and corrosion. This evolution will enable V belt pulleys to withstand harsher operating conditions, ultimately extending their lifespan and reliability in various applications.

Additionally, the incorporation of smart technology is set to redefine the functionality of V belt pulleys. Sensors embedded within the pulleys can monitor performance metrics in real-time, allowing for proactive maintenance and reducing downtime. This predictive approach to maintenance ensures optimal performance while minimizing the risk of unexpected failures. Furthermore, the rise of automation and Industry 4.0 principles will likely lead to more precise manufacturing processes, enhancing the overall quality and consistency of V belt pulleys. As these innovations unfold, users can expect V belt systems that not only meet but exceed current performance standards.