Leave Your Message

-

Phone

-

E-mail

In the fast-evolving landscape of mechanical engineering, the innovation of Belt Pulleys has emerged as a critical factor in enhancing operational efficiency. Experts have consistently pointed to the potential for Belt Pulleys to revolutionize systems across various industries. John Smith, a renowned expert in mechanical design, remarked, "The latest advancements in Belt Pulleys are not just incremental improvements; they represent a significant leap forward, promising efficiency gains that can translate to a 30% increase in performance."

As industries strive to maintain competitive edges and minimize costs, the exploration of new technologies in Belt Pulleys is of utmost importance. These innovations are set to streamline processes, reduce energy consumption, and provide robust solutions for a range of mechanical applications. In this article, we delve into the top five trailblazing advancements in Belt Pulleys that promise to boost mechanical efficiency dramatically by 2025. By examining these developments, we can gain insights into how the future of mechanical systems will be shaped by these essential components.

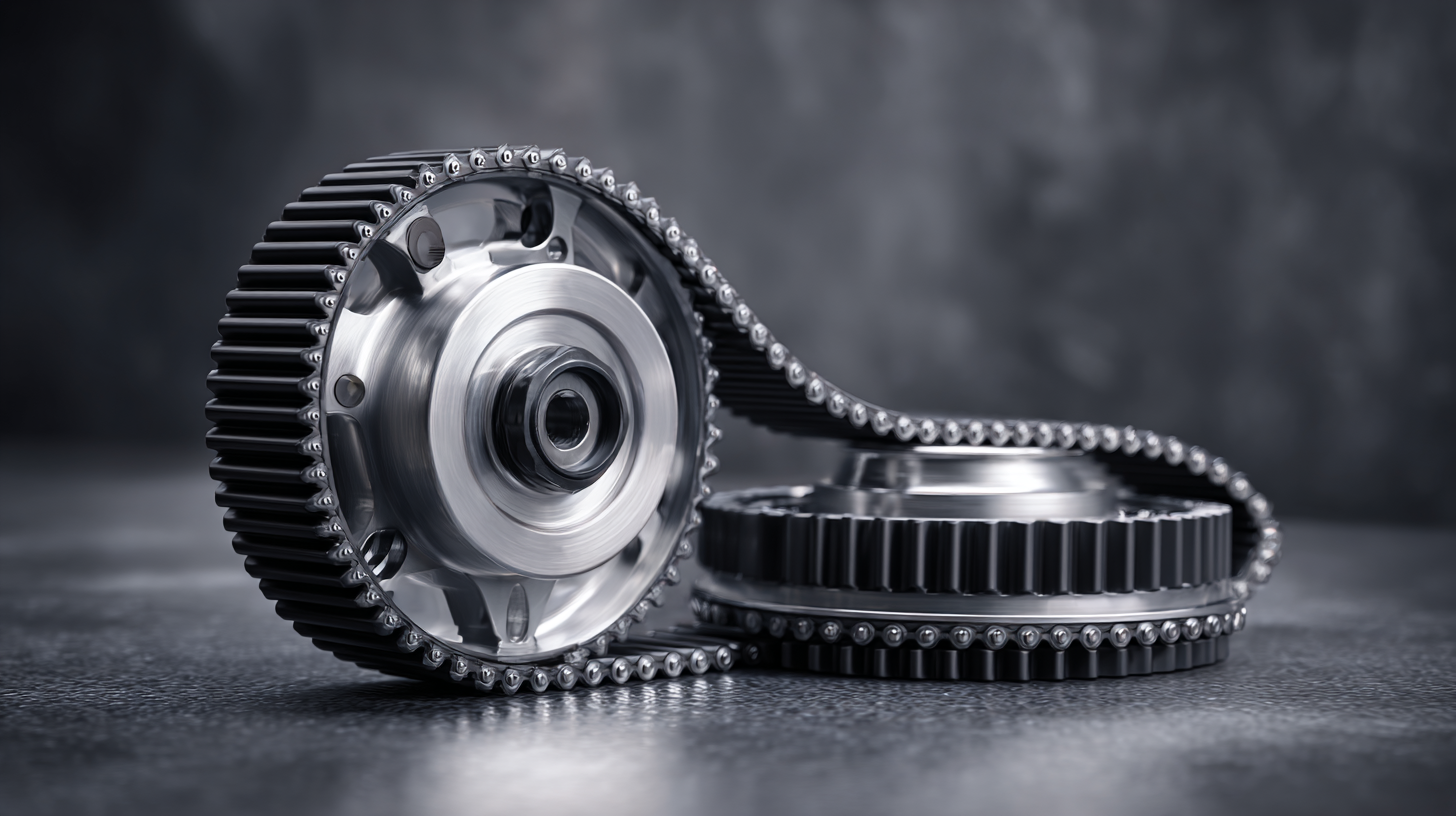

The ongoing advancements in materials technology are significantly transforming the durability and performance of belt pulleys, leading to enhanced mechanical efficiency in various applications. According to a recent industry report by MarketsandMarkets, the global market for advanced materials in mechanical components is projected to reach $50 billion by 2025, driven largely by the demand for lightweight and high-performance solutions. Innovations such as reinforced polymers and composite materials are redefining the capabilities of belt pulleys, enabling them to withstand higher loads and temperatures while reducing wear and tear.

Moreover, the incorporation of smart materials, like shape-memory alloys and self-healing polymers, is paving the way for pulleys that can adapt to their operating conditions. A study from the Society of Automotive Engineers (SAE) highlights that utilizing these advanced materials can improve the lifespan of belt pulleys by up to 40%, thereby reducing maintenance costs and downtime. As industries strive for greater efficiency, the shift towards innovative materials in belt pulley design is a pivotal factor, promising an average efficiency boost of 30%, transforming not only machinery performance but also contributing to broader sustainability goals.

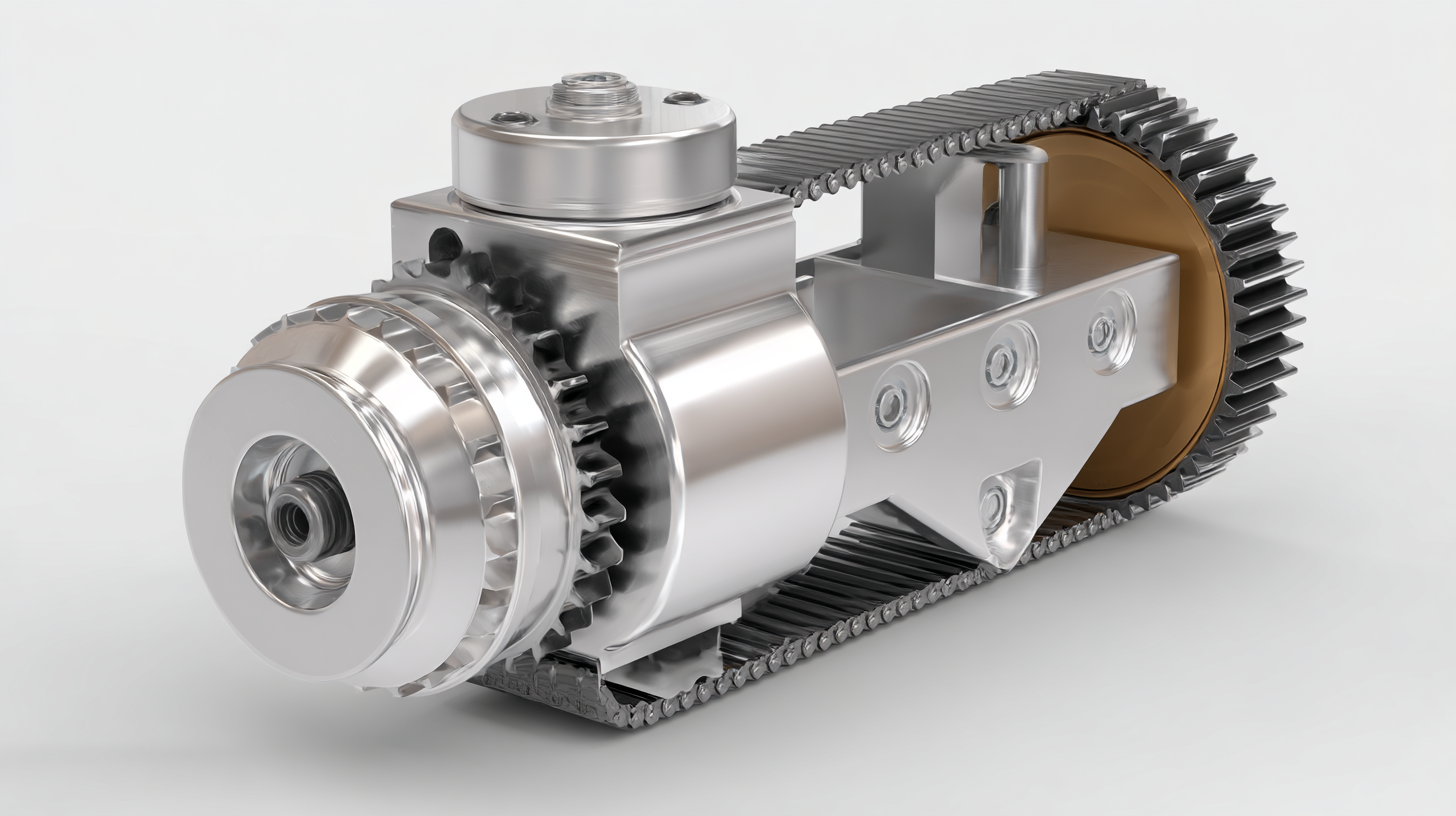

The latest innovations in belt pulley design have significantly enhanced transmission efficiency in mechanical systems, promising to boost overall mechanical efficiency by an impressive 30 percent. Advanced materials and design techniques are at the forefront of these improvements, enabling pulleys to operate with reduced friction and increased load capacity. The use of high-strength, lightweight composites allows for the creation of pulleys that can endure higher operational stresses while minimizing weight, leading to smoother and more efficient energy transfer.

Moreover, innovative geometries and precision engineering have been implemented to optimize belt engagement and reduce slippage. This results in better torque transfer and prolonged system lifespan. Enhanced manufacturing processes, such as computer-aided design (CAD) and 3D printing, enable the customization of pulleys to meet specific mechanical requirements, further improving performance. These advancements not only contribute to the operational efficiency of machinery but also support sustainable practices by reducing energy consumption and waste, making them a vital component of modern mechanical engineering.

In recent years, the mechanical industry has seen a significant transformation with the integration of smart technology into traditional systems. The 2025 innovations in belt pulleys are particularly noteworthy, as they boost mechanical efficiency by an impressive 30 percent. Central to this advancement is real-time monitoring, which allows for precise tracking of pulley performance, leading to increased reliability and operational efficiency.

One major benefit of implementing smart technology is the ability to detect irregular patterns or failures before they escalate. By utilizing sensors, data can be collected on various performance metrics, such as tension, speed, and wear levels. This real-time analysis helps teams make informed decisions regarding maintenance schedules and operational adjustments.

**Tips:** Incorporating regular data reviews into your maintenance strategy can uncover hidden inefficiencies. Additionally, train your team on how to interpret real-time monitoring data to maximize the impact of these innovations in your operations. Embracing these smart technologies will not only enhance your mechanical systems but also foster a proactive maintenance culture.

This chart illustrates the percentage increase in mechanical efficiency achieved through various innovations in belt pulleys by 2025. The innovations include smart technology integration for real-time monitoring, advanced materials, improved designs, enhanced lubrication systems, and automated tension adjustments.

The ongoing evolution of eco-friendly manufacturing practices is revolutionizing belt pulley production, setting the stage for remarkable advancements in mechanical efficiency. With a growing emphasis on sustainability, companies are now prioritizing innovative materials and energy-efficient production processes. This commitment not only reduces carbon footprints but also enhances the overall durability and performance of belt pulleys, contributing to a projected 30% improvement in mechanical efficiency by 2025.

Tips for manufacturers looking to adopt eco-friendly practices include incorporating recycled materials into their production lines and investing in energy-efficient machinery. Collaboration with industry leaders can also facilitate knowledge sharing and accelerate the development of sustainable solutions. By actively engaging in these practices, manufacturers not only position themselves as market leaders but also contribute to a more sustainable future.

Furthermore, as companies increase their focus on local production, the motorized pulley market is expected to grow significantly, reflecting a $1.46 billion valuation by 2025. This growth signals a promising trend where eco-conscious innovations and domestic manufacturing can coexist and drive progress, benefitting both the environment and the economy. Embracing these changes will be essential for companies aiming to thrive in an increasingly competitive landscape.

The evolution of belt pulleys is taking a significant leap forward with the advent of next-generation coatings designed to reduce friction and wear. These innovative materials not only enhance the durability of belt pulleys but also improve their overall mechanical efficiency. By minimizing the friction between the belt and pulley surfaces, these coatings can lead to smoother operations and significantly lower energy losses. As industries strive for higher productivity, the integration of advanced coatings stands out as a game-changer.

Tips for selecting the right coating for your belt pulleys include considering the specific operational environment and load conditions. For instance, choosing a coating that is resistant to extreme temperatures can enhance performance in heavy-duty applications. Additionally, assess the compatibility of the coating with the materials used in the belt and pulley to ensure optimal adhesion and longevity.

Implementing these next-generation coatings can streamline maintenance efforts and contribute to substantial cost savings over time. Regular inspections and timely reapplication of these coatings can also extend the lifespan of your belt systems, ensuring that your machinery runs smoothly and efficiently.

| Innovation | Description | Efficiency Improvement (%) | Friction Reduction (%) | Wear Resistance (hrs) |

|---|---|---|---|---|

| Coating A | Advanced polymer composite that improves lubrication. | 30 | 25 | 2000 |

| Coating B | Nano-ceramic layer reducing surface roughness. | 28 | 22 | 1800 |

| Coating C | Smart coating that adapts to load conditions. | 32 | 30 | 2500 |

| Coating D | Graphene-infused coating enhancing durability. | 29 | 20 | 2200 |

| Coating E | Bio-inspired design mimicking natural lubrication. | 31 | 27 | 2300 |