Leave Your Message

-

Phone

-

E-mail

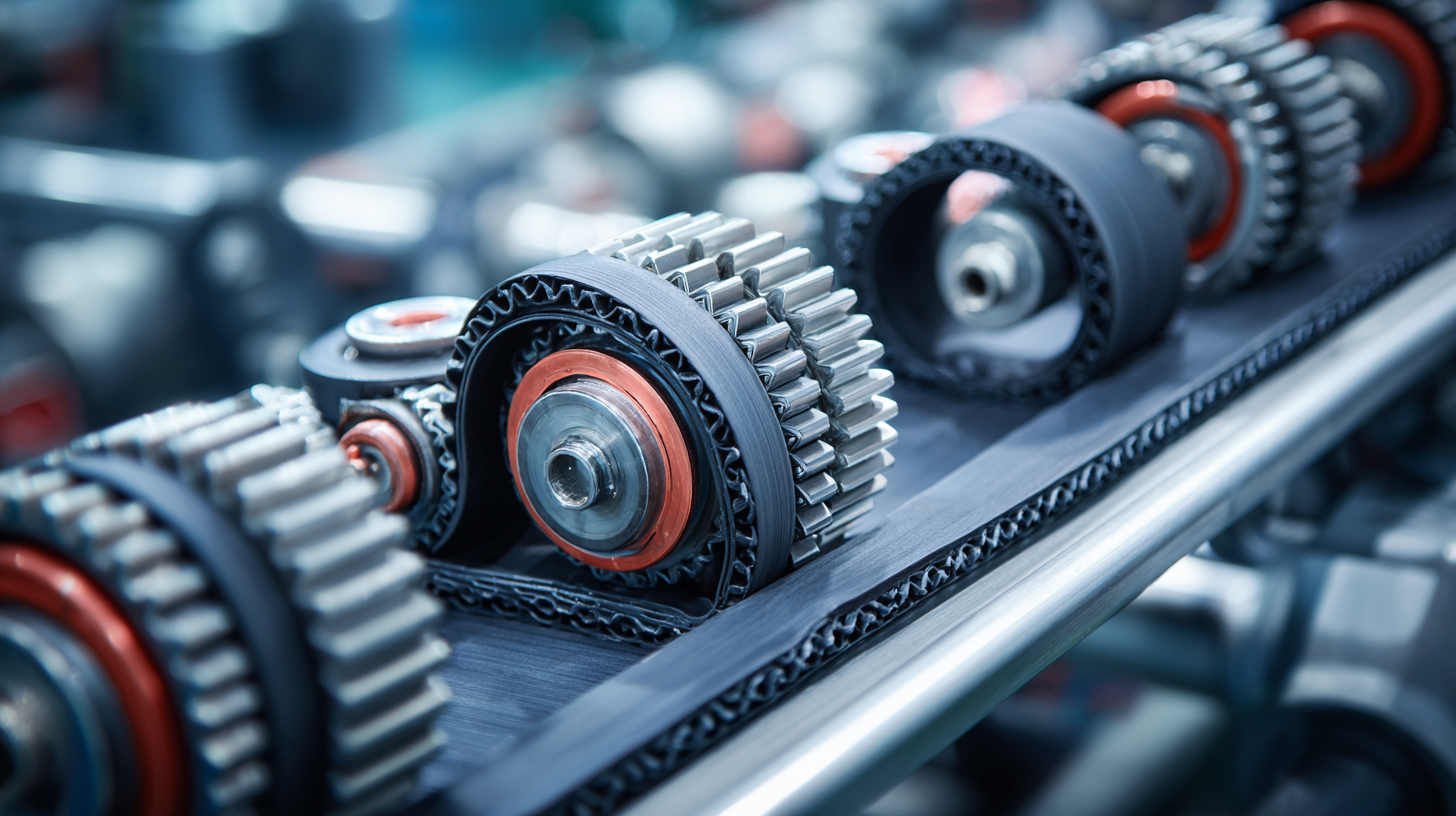

In today's fast-paced industrial landscape, efficiency and reliability are paramount for the optimal performance of machinery. One of the key components that significantly contributes to this efficiency is the Rubber V Belt. As a vital link in power transmission systems, Rubber V Belts enable smoother operations and reduced wear and tear on machinery. Their unique design and material properties allow them to handle various loads, making them indispensable in a wide range of applications from automotive to manufacturing industries.

Understanding the importance of Rubber V Belts extends beyond mere functionality; it also encompasses their role in enhancing overall operational productivity. From improving energy efficiency to minimizing downtime, these belts provide manufacturers and operators with the assurance that their machinery can perform at peak levels. This article will delve into the "Top 10" reasons why Rubber V Belts should be acknowledged as a cornerstone of modern mechanical systems, highlighting their impact on both the longevity of machinery and the reduction of operational costs.

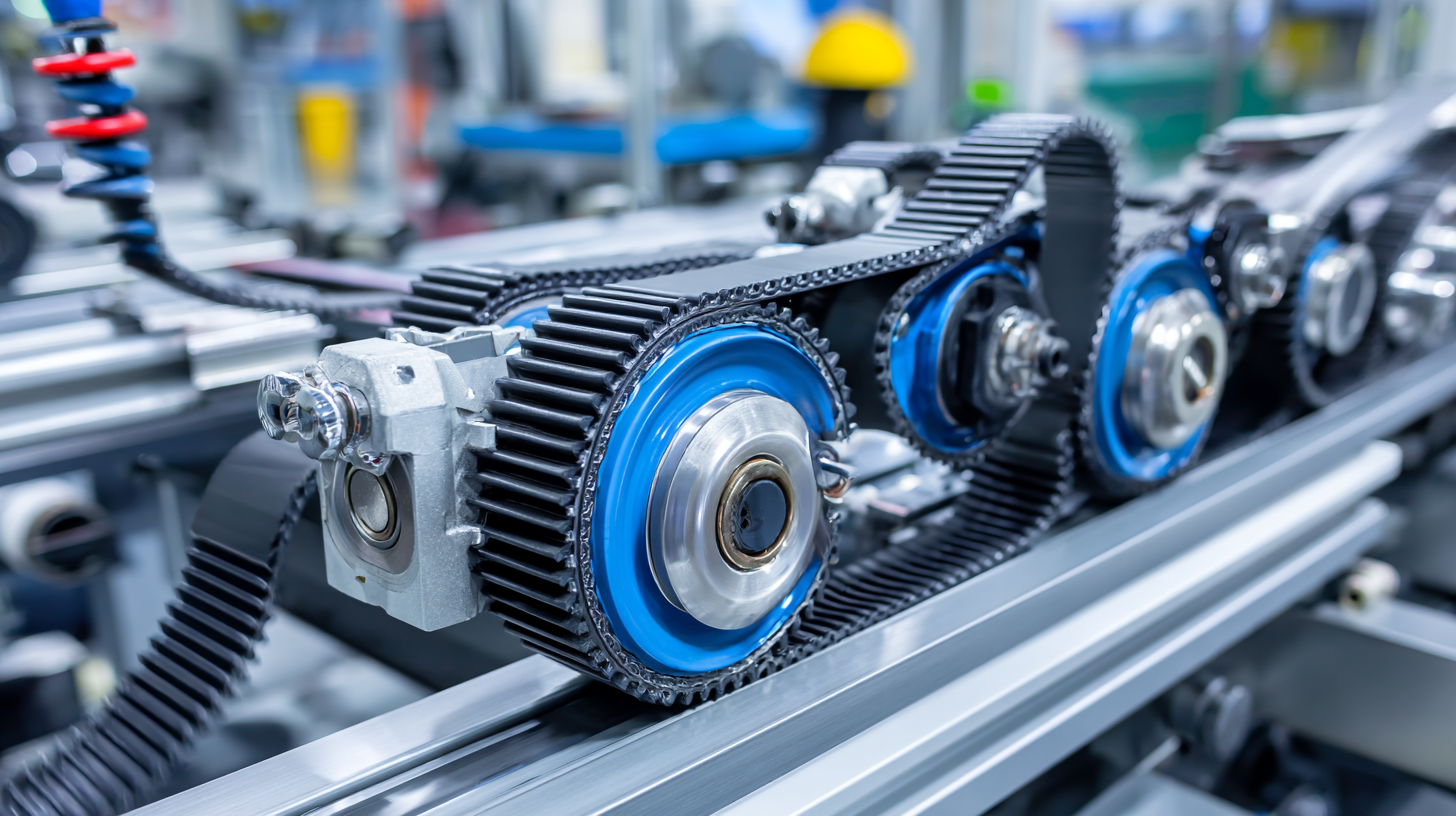

Rubber V belts play a crucial role in enhancing power transfer efficiency within modern machinery. These belts effectively transmit power between rotating components, ensuring smooth operation and reducing energy loss. The demand for advanced rubber materials is propelling the adoption of these belts among leading automotive engine belts and hoses companies, as they seek to optimize performance and durability. Innovations such as short fiber reinforced elastomeric composites are being developed to improve mechanical and tribological properties, addressing the needs of demanding engineering applications.

As the global market for standard V belts is projected to reach USD 261.5 million by 2035, this underscores the importance of investing in high-quality materials and sustainable solutions. Companies are actively focusing on improving efficiency and sustainability, as seen in initiatives to divert waste from landfills and the continuous pursuit of better performance in power transmission technologies. With a forecast of growth in the power transmission belting market, the emphasis on rubber V belts will play a significant role in meeting the evolving demands of various industries.

High-performance rubber V belts play a crucial role in modern machinery, ensuring efficiency and reliability in various applications. One of their key characteristics is their superior flexibility, which enables them to transmit power smoothly between pulleys. This flexibility reduces wear and tear, prolonging the lifespan of both the belt and the machinery it serves. Moreover, high-performance rubber V belts are designed to operate under a wide range of temperatures and load conditions, making them ideal for demanding environments.

High-performance rubber V belts play a crucial role in modern machinery, ensuring efficiency and reliability in various applications. One of their key characteristics is their superior flexibility, which enables them to transmit power smoothly between pulleys. This flexibility reduces wear and tear, prolonging the lifespan of both the belt and the machinery it serves. Moreover, high-performance rubber V belts are designed to operate under a wide range of temperatures and load conditions, making them ideal for demanding environments.

Another significant characteristic is their high tensile strength, which ensures they can handle substantial loads without stretching or breaking. This property is essential for heavy-duty machinery where consistent performance is critical. Additionally, the advanced rubber compounds used in these belts provide excellent resistance to abrasion, oil, and heat, further enhancing their durability. The combination of these features not only improves the overall efficiency of the machinery but also minimizes maintenance costs and downtime, making rubber V belts an indispensable component in modern industrial applications.

Rubber V belts play a crucial role in enhancing the durability of modern machinery. Their design allows for efficient power transmission between various components, which helps in reducing wear and tear. The flexibility and elasticity of rubber make these belts capable of absorbing shocks and vibrations, thus minimizing the stress on machinery parts. This ability not only prolongs the life of the equipment but also ensures operations run smoothly, reducing the likelihood of unexpected breakdowns.

Moreover, effective maintenance of rubber V belts can significantly impact overall machinery efficiency. Regular inspections can identify signs of wear, such as cracks or fraying, allowing for timely replacements before they lead to more severe mechanical failures. Furthermore, proper tensioning and alignment can enhance the belt's performance, ensuring that energy transfer remains efficient and reducing energy losses. By prioritizing the maintenance of rubber V belts, organizations can extend the operational lifespan of their machinery, lower repair costs, and improve service reliability.

Rubber V belts play a crucial role in enhancing the efficiency of modern machinery, particularly when compared to alternative belt types. The automotive engine belt and hoses market, for instance, illustrates the growing significance of rubber belts. According to a recent analysis, the standard V belts market is projected to reach USD 261.5 million by 2035, driven by a compound annual growth rate (CAGR) of 4.1% from 2025 to 2035. This indicates a sustained demand for rubber V belts, demonstrating their vital role in automotive applications, where reliability and performance are paramount.

In the broader landscape, the rubber conveyor belt market, valued at USD 3.9 billion in 2024, is expected to grow to USD 5.8 billion by 2034, marking a CAGR of 4% over the same period. Such statistics emphasize the advantages of rubber V belts over their alternatives, such as fabric or metal belts, especially in handling heavy loads and maintaining consistent transmission efficiency. The comparative resilience and flexibility of rubber V belts render them indispensable in various industrial sectors, making them a preferred choice among manufacturers aiming to optimize machinery performance and durability.

| Belt Type | Material | Efficiency (%) | Durability (Hours) | Cost ($/m) | Maintenance Frequency (Months) |

|---|---|---|---|---|---|

| Rubber V Belt | Rubber | 95 | 5000 | 5 | 6 |

| Polyester Belt | Polyester | 90 | 7000 | 4 | 12 |

| Flat Belt | Cotton/Polyester | 85 | 4000 | 3 | 8 |

| Timing Belt | Nylon/Polyurethane | 92 | 6000 | 6 | 10 |

| Chain Drive | Metal | 80 | 8000 | 7 | 5 |

The integration of rubber V belts in modern machinery is witnessing a significant evolution, driven by advancements in technology and a growing emphasis on efficiency. Future trends indicate a shift towards enhanced materials and designs that improve the performance and lifespan of these essential components. A report by Grand View Research highlights that the global V belt market size is expected to reach USD 3.4 billion by 2025, fueled by the increasing demand for efficient energy transmission in mechanical systems. This growth is largely attributed to innovative developments in rubber compounds and reinforcement technologies.

Moreover, as industries lean towards automation and smart machinery, the integration of rubber V belts with IoT and predictive maintenance systems is becoming more prevalent. According to a study by Research and Markets, the smart manufacturing market, which includes machinery using advanced components like V belts, is projected to surpass USD 500 billion by 2025. This indicates a clear trend where rubber V belts are not only serving their traditional purpose but are also becoming key players in the evolving landscape of industrial efficiency, ensuring that machines operate at optimal performance levels while reducing downtime and maintenance costs.