Leave Your Message

-

Phone

-

E-mail

In the realm of modern engineering, the demand for precision and efficiency has led to the widespread adoption of innovative mechanical systems. Among these, the rack pinion system stands out as a fundamental component that facilitates motion and control in various applications. This mechanical configuration, consisting of a linear rack and a rotating pinion gear, plays a crucial role in converting circular motion into linear motion, enabling engineers to design more effective and dynamic solutions for complex challenges.

The significance of rack pinion systems transcends traditional applications, finding their place in advanced fields such as robotics, automotive engineering, and aerospace technologies. By providing precise positioning and smooth operation, they enhance the functionality of mechanical devices ranging from simple sliding doors to intricate robotic arms. Moreover, the adaptability of rack pinion systems allows engineers to implement them in a variety of environments, ensuring that they meet the unique demands of each project while optimizing performance.

As industries continue to evolve and embrace technological advancements, the importance of incorporating reliable and efficient mechanisms like rack pinion systems cannot be overstated. This introduction aims to explore the critical role these systems play in modern engineering solutions, highlighting their versatility and impact across a spectrum of applications.

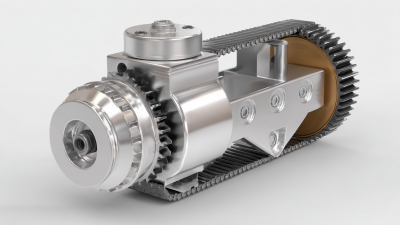

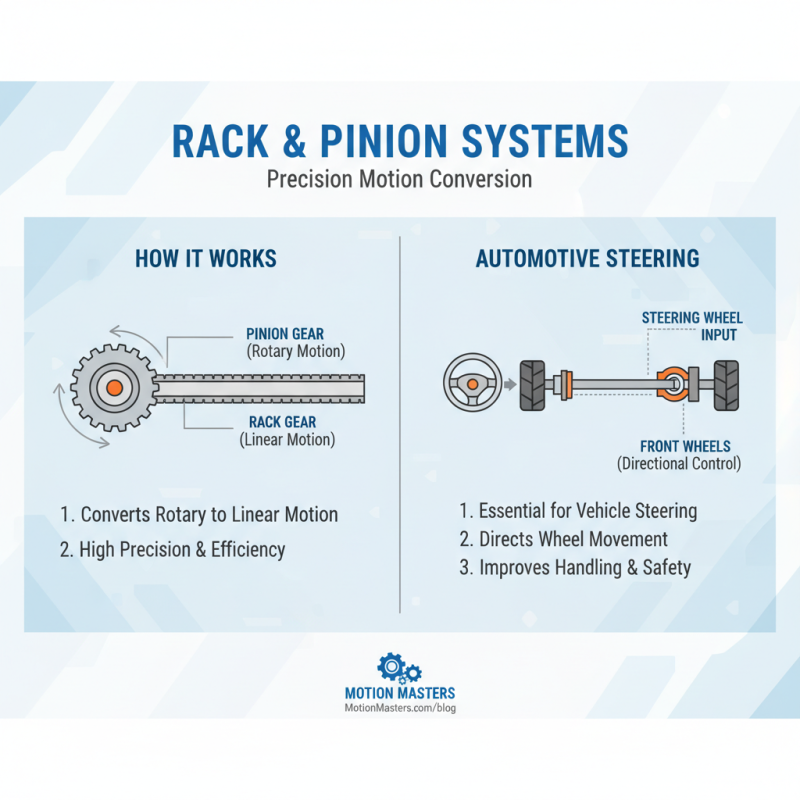

Rack and pinion mechanisms are fundamental components in modern engineering, converting rotational motion into linear movement. The system consists of two main parts: a cylindrical gear known as the pinion and a linear gear called the rack. When the pinion rotates, its teeth engage with the rack, resulting in straightforward motion. This simplicity and efficiency make rack and pinion systems ideal for applications ranging from automotive steering to industrial machinery.

One of the key advantages of rack and pinion mechanisms is their ability to provide precise control over movement. Engineers can easily calculate the required gear ratios to achieve desired speeds and forces, making these systems adaptable for various mechanical applications. Additionally, the direct connection between rotational and linear motion enhances reliability, as there are fewer components subject to wear and potential failure. As industries seek innovative solutions that prioritize efficiency and accuracy, the significance of rack and pinion systems continues to grow in the field of engineering.

Rack and pinion systems play a pivotal role in a variety of industries due to their precision and efficiency in converting rotary motion into linear motion. In the automotive sector, these systems are essential for steering mechanisms, allowing for smooth and responsive vehicle handling. By directly linking the steering wheel to the wheels through a rack and pinion setup, drivers gain critical control and maneuverability, enhancing safety and driving experience.

In the manufacturing and robotics fields, rack and pinion systems are used in automated machinery and conveyor systems. This technology enables precise linear movements essential for tasks such as assembly, packaging, and material handling. The reliability of rack and pinion systems in high-load applications ensures that manufacturing processes can run smoothly and efficiently, minimizing downtime and maintenance costs. Additionally, these systems find applications in the aerospace sector, powering flight control surfaces, and in the entertainment industry, facilitating the operation of stage equipment and theme park rides, where accurate positioning is crucial for both safety and user experience.

Rack and pinion systems have emerged as a foundational component in modern engineering due to their exceptional efficiency and versatility. One of the primary advantages of rack and pinion mechanisms is their ability to convert rotational motion into linear motion with minimal backlash. Research from the American Society of Mechanical Engineers (ASME) indicates that these systems can achieve precision within 0.02 mm, which is crucial for applications in robotics, CNC machinery, and automotive steering systems. This level of accuracy is often superior to other linear drive technologies, such as lead screws or ball screws, which can suffer from increased friction and wear over time.

Moreover, the simplicity of the rack and pinion design contributes to lower manufacturing and maintenance costs. According to a study published by the International Journal of Engineering Research and Applications, systems utilizing rack and pinion configurations can lead to cost reductions of up to 20% in mechanical assembly compared to alternative mechanisms. Their fewer moving parts and robust construction make them less susceptible to failure and ensure longevity in demanding environments. Additionally, rack and pinion systems are easily scalable, accommodating various applications from small-scale robotics to large industrial machines, making them highly favorable in the rapidly evolving engineering landscape.

| Dimension | Rack and Pinion | Other Mechanisms |

|---|---|---|

| Precision | High accuracy | Variable accuracy |

| Speed | Fast operation | Slower response |

| Load Capacity | High load capability | Limited capacity |

| Maintenance | Low maintenance | More frequent maintenance |

| Versatility | Highly versatile | Limited versatility |

Innovations in rack and pinion technology have significantly transformed how mechanical systems operate across various industries. One of the most notable advancements is the integration of smart materials and sensors, which enhance the precision and responsiveness of these systems. By incorporating real-time data feedback, engineers can optimize the performance of rack and pinion mechanisms, improving their efficiency and adaptability in dynamic environments. This shift towards automation and smart technology is a critical component in the evolution of modern machinery, enabling the design of systems that can adjust and respond to changing conditions seamlessly.

Future trends in rack and pinion systems are leaning towards miniaturization and advanced materials. The development of stronger yet lighter composite materials can lead to more compact designs without sacrificing strength. Additionally, with the rise of additive manufacturing, it is becoming possible to create customized rack and pinion components that are specifically tailored for unique applications. This innovation not only decreases material waste but also allows for rapid prototyping, facilitating faster development cycles in engineering solutions. As industries continue to seek efficient and sustainable practices, the future of rack and pinion technology looks promising, paving the way for groundbreaking advancements in engineering.

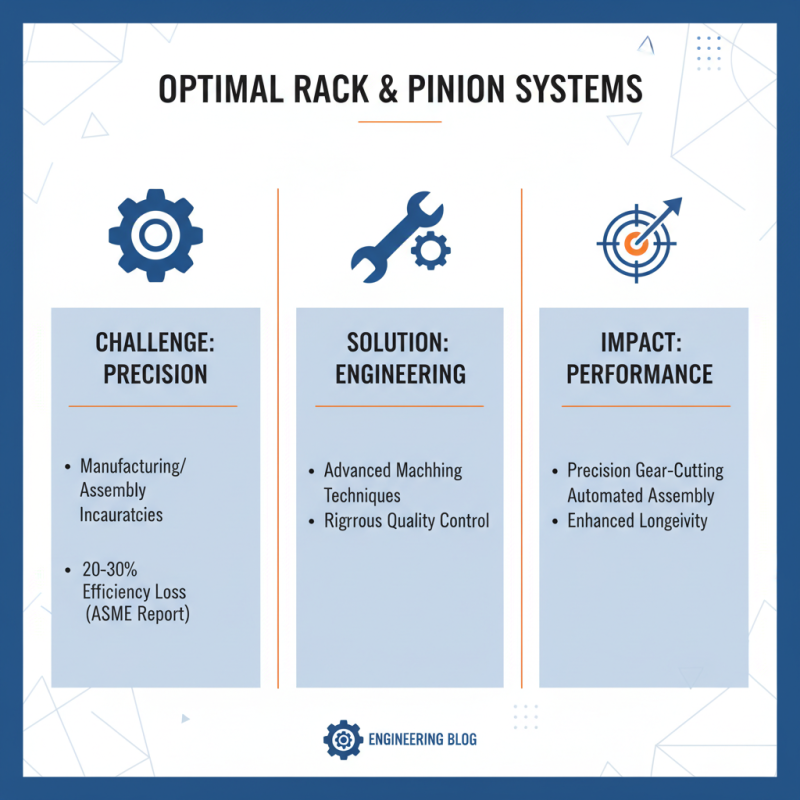

Implementing rack and pinion systems in modern engineering poses several challenges that need to be addressed for optimal performance. One significant challenge is ensuring precision in manufacturing and assembly. According to a report by the American Society of Mechanical Engineers, inaccuracies in gear alignment can lead to a 20-30% reduction in system efficiency. To mitigate this issue, engineers often employ advanced machining techniques and rigorous quality control measures. Employing precision gear-cutting technologies and utilizing automation in assembly processes can lead to better alignment, which enhances the overall performance and longevity of rack and pinion systems.

Another critical challenge is the selection of materials that can withstand the rigors of operation while maintaining high durability and resilience. A study published by the International Journal of Engineering Research highlighted that over 40% of rack and pinion failures are attributed to material fatigue, especially in high-stress applications. To counteract this, engineers are increasingly turning to innovative materials, such as high-strength composites and alloyed steels, that offer superior wear resistance and lower friction coefficients. Additionally, incorporating lubrication technologies can significantly improve the lifespan of these systems, providing a solution to one of the most prevalent issues faced in mechanical design today.