Leave Your Message

-

Phone

-

E-mail

In the realm of modern engineering, the importance of precision and efficiency cannot be overstated. Among the various mechanical systems that facilitate these qualities, the rack pinion mechanism stands out for its versatility and effectiveness. This essential apparatus converts rotational motion into linear motion, making it a critical component in a wide range of applications, from automotive steering systems to industrial machinery. Understanding the principles and advantages of rack pinion mechanisms is vital for engineers seeking to innovate and optimize their designs.

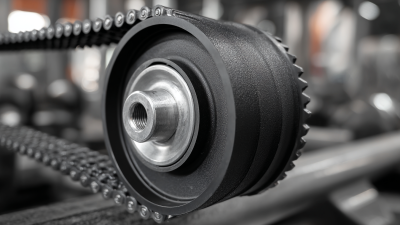

The rack pinion mechanism consists of two main components: a circular gear (the pinion) and a linear bar with teeth (the rack). When the pinion rotates, its teeth engage with the rack, causing it to move linearly. This simple yet effective design allows for precise control and high load capacity, which is crucial in demanding environments. As industries continue to evolve, the reliance on such mechanisms in applications requiring reliability and precision only increases, proving that the rack pinion is not just a fundamental mechanical element but a pillar of modern engineering excellence.

Rack and pinion mechanisms play a crucial role in various modern engineering applications due to their simplicity and efficiency in converting rotational motion into linear motion. According to a report by MarketsandMarkets, the global linear motion system market is projected to grow from $7.92 billion in 2022 to $11.42 billion by 2027, reflecting an increasing demand for precise linear drive systems. This growth can be largely attributed to the efficient functionality of rack and pinion systems, which are widely used in manufacturing, automotive, and aerospace sectors for tasks ranging from steering mechanisms to automated assembly processes.

Moreover, the accuracy and reliability of these mechanisms make them indispensable in applications requiring high precision. A study published in the Journal of Mechanical Engineering highlights that rack and pinion gears provide a repeatable linear position that can be crucial in robotic arms and CNC machines, where precision is paramount. The ease of integration with various automation technologies further emphasizes their importance, enabling enhanced performance while minimizing friction and wear. As engineering continues to advance, the significance of rack and pinion mechanisms in achieving efficient and reliable motion control will only increase, making them essential in modern engineering designs.

Rack and pinion systems have become integral components in various industrial machinery applications due to their efficiency in converting rotational motion to linear motion. One prominent application is in CNC (Computer Numerical Control) machines, where precision is paramount. The rack and pinion mechanism ensures the smooth and precise movement of cutting tools along multiple axes, allowing for high accuracy in machining components. This capability not only enhances productivity but also reduces the wear and tear on machinery, prolonging service life.

Another critical application of rack and pinion systems is in material handling equipment, such as conveyor systems and hoists. In these contexts, the rack and pinion arrangement allows for reliable movements of loads over considerable distances without sacrificing speed or stability. The direct engagement between the rack and pinion teeth enables the system to handle heavy weights while maintaining accuracy and safety, which is essential in environments like warehouses and manufacturing plants. The robust design of these mechanisms also means they can withstand substantial operational stress, making them ideal for heavy-duty applications.

| Application Area | Description | Key Features | Advantages |

|---|---|---|---|

| Automotive Industry | Used in steering mechanisms for precise vehicle handling. | High precision, responsiveness, and durability. | Improves driver control and safety. |

| Manufacturing Automation | Utilized in CNC machines for accurate positioning. | High speed, precise linear movement. | Enhances production efficiency and output quality. |

| Material Handling | Applied in conveyor systems for material transportation. | Robust structure, smooth operation. | Minimizes operational downtimes and maintenance costs. |

| Robotics | Essential in robotic arms for precise movement. | Compact design, low backlash. | Increases precision in automated tasks. |

| Aerospace | Used in control surfaces for aircraft. | High reliability, lightweight materials. | Enhances flight safety and maneuverability. |

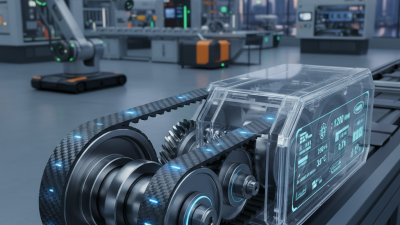

Rack and pinion mechanisms are critical in modern engineering applications due to their ability to convert rotary motion into linear motion with high precision. Performance metrics such as efficiency and backlash play a significant role in determining their effectiveness in various industries. According to a report by the International Journal of Mechanical Engineering, systems utilizing rack and pinion designs can achieve efficiency rates of up to 90% under optimal conditions, primarily due to their simple design and direct connection between components. This high level of efficiency minimizes energy consumption and maximizes output, making rack and pinion systems highly desirable for applications in robotics, automotive steering, and CNC machinery.

Furthermore, the efficiency of rack and pinion mechanisms is often influenced by factors such as material selection and gear tooth profile. Research conducted by the Journal of Manufacturing Science and Engineering indicates that implementations with optimized gear tooth geometry can reduce backlash to less than 0.05 mm, significantly enhancing precision in applications where minute positional adjustments are crucial. Enhanced performance metrics result in improved reliability and longevity of systems, which is especially vital in industries that demand continuous operation under demanding conditions. With the ongoing advancements in materials and manufacturing techniques, rack and pinion systems are evolving to meet the increasing performance requirements set forth by modern engineering challenges.

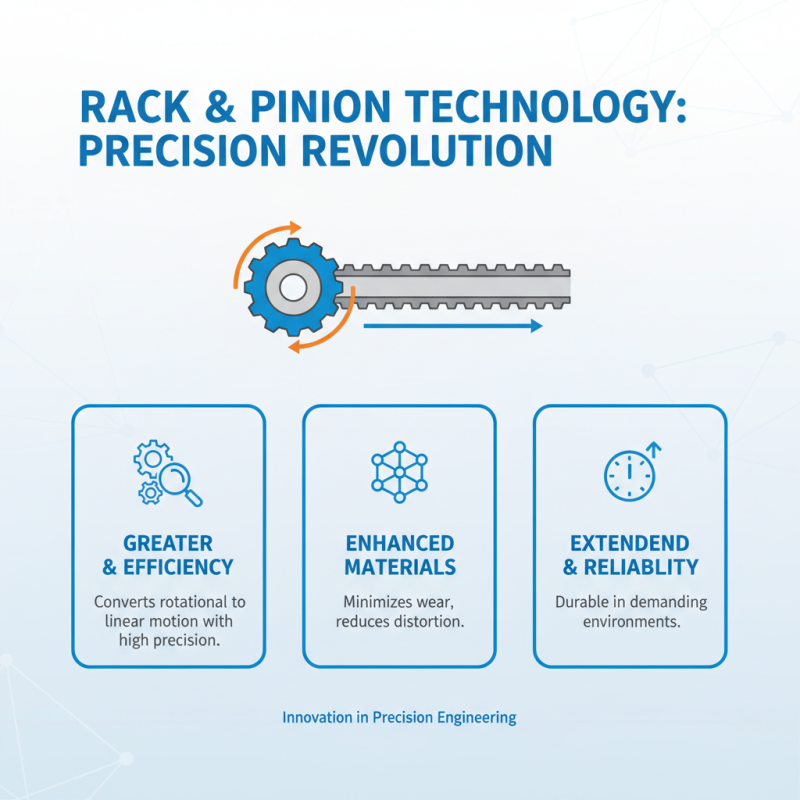

Recent advancements in rack and pinion technology have revolutionized precision engineering, making it possible to achieve greater accuracy and efficiency in various applications. These mechanisms, consisting of a linear gear (the rack) and a circular gear (the pinion), convert rotational motion into linear motion with high precision. Innovations such as enhanced materials and manufacturing processes have led to racks and pinions that minimize wear and distortion, thus extending their lifespan and reliability in demanding environments.

Moreover, the integration of computerized control systems has significantly improved the functionality of rack and pinion setups. These systems allow for real-time adjustments and monitoring, ensuring that the mechanisms operate within predefined parameters. The ability to fine-tune the performance characteristics results in better alignment, reduced backlash, and increased responsiveness, which are critical for applications such as robotics, CNC machining, and automated assembly lines. As the demand for precision in engineering continues to rise, the evolution of rack and pinion mechanisms remains pivotal in meeting these challenges.

The future of rack and pinion mechanisms is set to be shaped by advancements in materials science and automation technologies. As lighter and more durable materials are developed, the efficiency and performance of these mechanisms can be significantly enhanced. For instance, composite materials that offer high strength-to-weight ratios may reduce the overall weight of machines while increasing their load-bearing capacity. This evolution can lead to improved energy efficiency, making rack and pinion systems more viable for applications in industries like automotive and aerospace, where weight savings are critical.

Moreover, innovations in automation and smart technologies are poised to redefine how rack and pinion systems are employed. Integrating sensors and IoT capabilities into these mechanisms allows for real-time monitoring and predictive maintenance. This leads to enhanced reliability and prolonged service life, aligning with the growing demand for smart manufacturing solutions. Future iterations may also witness the incorporation of advanced control systems, enabling more precise movements and higher levels of automation across various engineering applications. As industries continue to pursue greater efficiency and performance, rack and pinion mechanisms will remain at the forefront of technological innovation.