Leave Your Message

-

Phone

-

E-mail

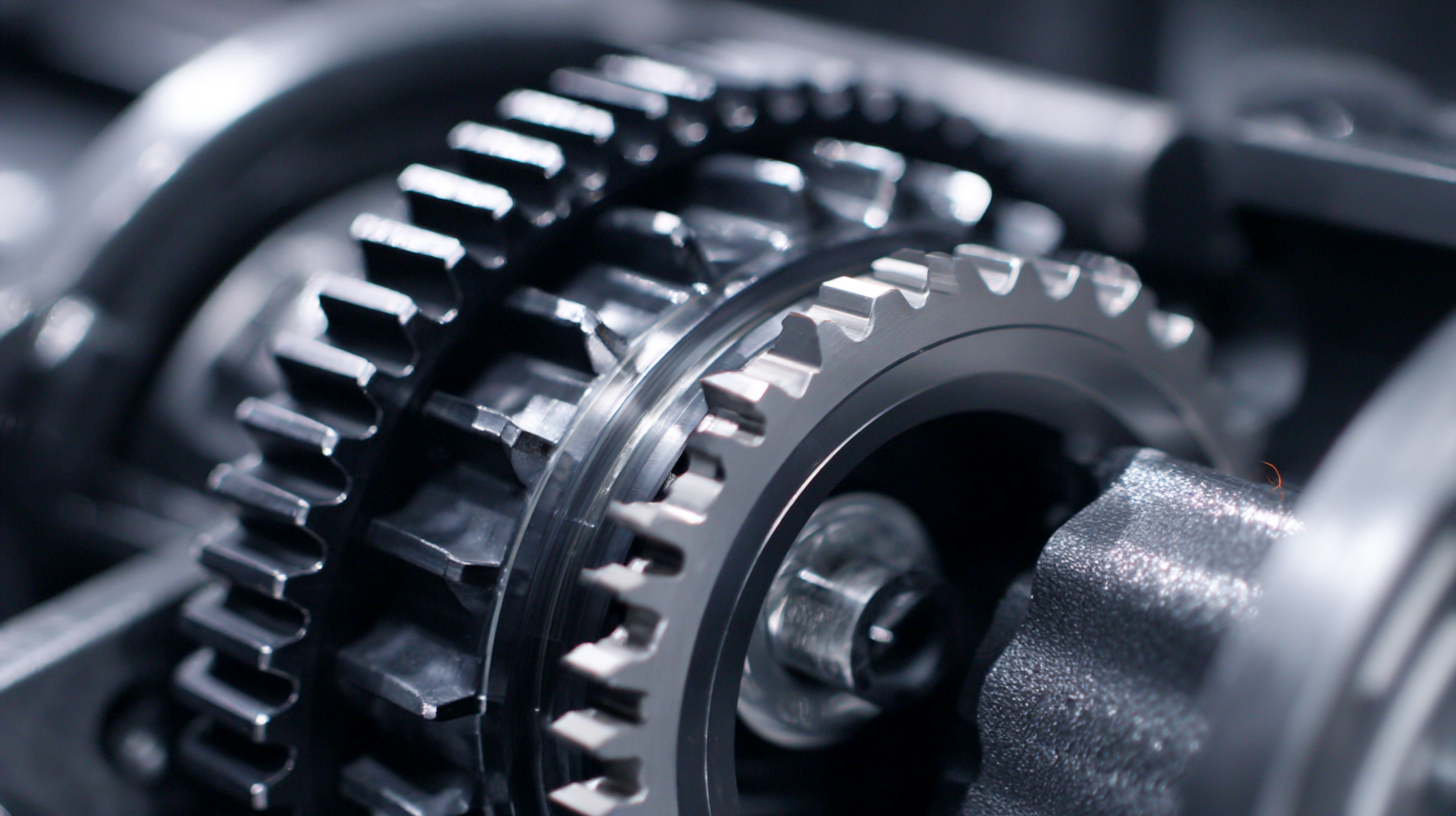

In the realm of mechanical engineering, the quest for enhanced efficiency is an ever-present challenge, leading to the exploration of innovative solutions. One such solution that has revolutionized the way we optimize mechanical systems is the Gearsbelt Pulley.

This ingenious component not only facilitates smoother power transmission but also significantly reduces friction and wear within the system, ultimately extending the lifespan of machinery. By harnessing the unique advantages offered by Gearbelt Pulleys, engineers can design systems that operate with remarkable precision and reliability.

This article delves into the various ways Gearbelt Pulleys transform mechanical systems, highlighting their role in maximizing efficiency and advancing technological capabilities across different industries. As we unpack the functionality and benefits of these pulleys, it becomes clear that they are not just components but pivotal elements in the evolution of mechanical systems.

This ingenious component not only facilitates smoother power transmission but also significantly reduces friction and wear within the system, ultimately extending the lifespan of machinery. By harnessing the unique advantages offered by Gearbelt Pulleys, engineers can design systems that operate with remarkable precision and reliability.

This article delves into the various ways Gearbelt Pulleys transform mechanical systems, highlighting their role in maximizing efficiency and advancing technological capabilities across different industries. As we unpack the functionality and benefits of these pulleys, it becomes clear that they are not just components but pivotal elements in the evolution of mechanical systems.

Gearbelt pulleys play a crucial role in enhancing the efficiency of mechanical systems. At their core, these components are designed to transmit power and motion, utilizing the principles of friction and traction between the belt and pulley. Understanding the key elements, such as the materials used and the geometry of the pulleys, is essential for optimizing their performance. The size and shape can significantly affect the speed and torque transfer, making it imperative to select the right pulley for specific applications.

**Tips:** When choosing gearbelt pulleys, consider the load requirements and the environment in which they will operate. Selecting materials that can withstand the specific conditions, such as high temperatures or corrosive elements, can enhance durability. Additionally, ensure proper alignment during installation to minimize wear and improve operational efficiency.

To achieve the best results, it's vital to regularly maintain gearbelt pulleys by checking for signs of wear and replacing belts as needed. This proactive approach not only extends the lifespan of the components but also ensures that the entire mechanical system operates smoothly and efficiently. Keep an eye on the tension of the belt as well; proper tension is critical to maintain effective power transmission without putting unnecessary strain on the pulleys.

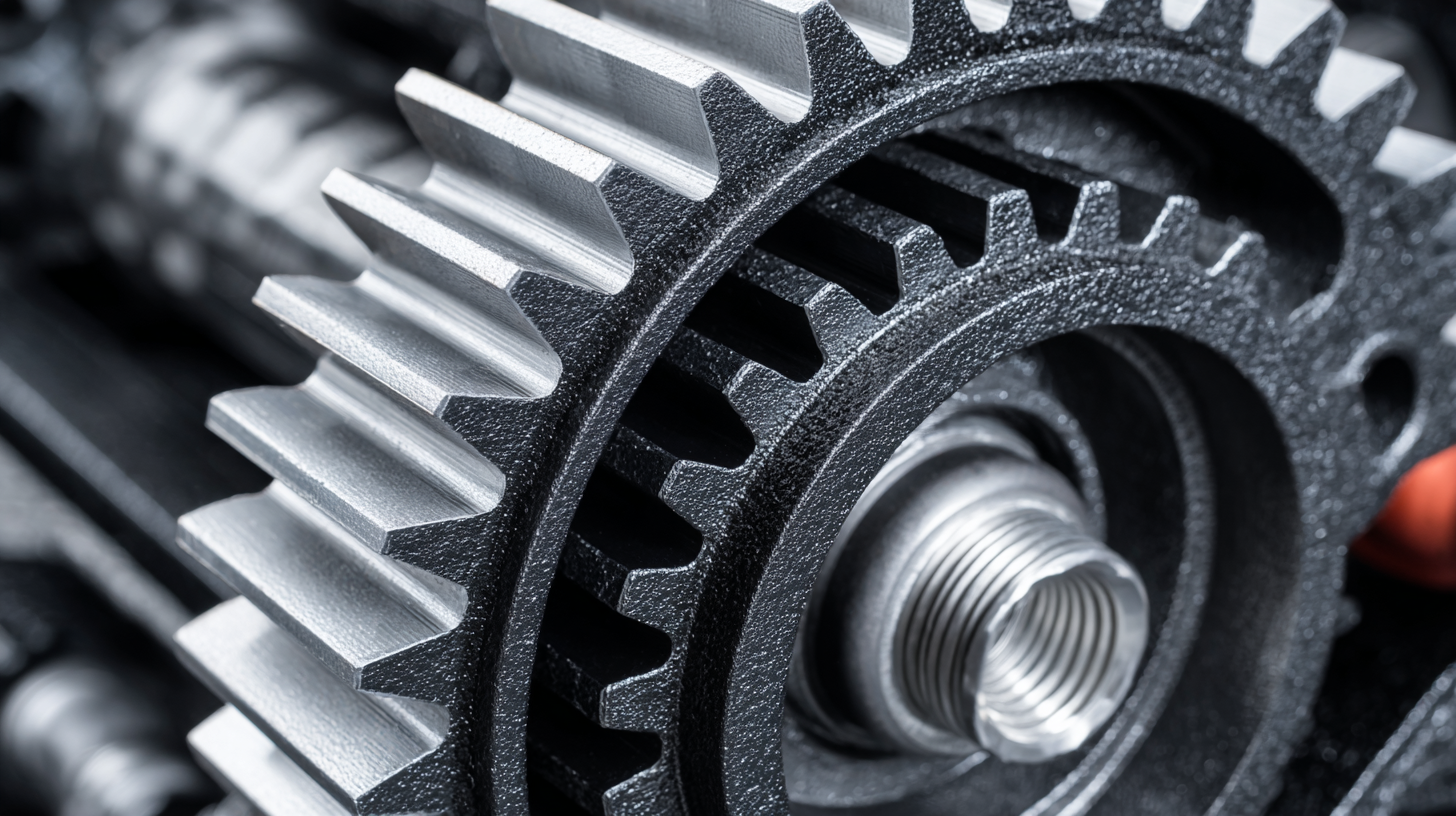

The performance and longevity of gearbelt pulleys are significantly influenced by material selection. Different materials offer varying degrees of strength, weight, and resistance to wear and environmental factors. For example, aluminum is often favored for its lightweight yet durable characteristics, making it suitable for high-speed applications. In contrast, materials like steel provide exceptional strength and are ideal for heavy-duty environments where durability is paramount. The right material choice not only enhances the efficiency of mechanical systems but also extends the lifespan of the pulleys, reducing maintenance costs over time.

Additionally, the impact of advanced composite materials cannot be understated. Composites can offer a unique combination of lightness and high tensile strength, which can lead to reduced energy consumption during operation. This is particularly beneficial in systems where minimizing weight can lead to improved overall performance. Moreover, the resistance of certain materials to corrosion and temperature fluctuations is crucial in industries like automotive and aerospace, where failure is not an option. Thus, understanding the properties of each material and its application in gearbelt pulley manufacture is essential for maximizing efficiency and ensuring sustained performance in mechanical systems.

In the realm of industrial applications, the implementation of gearbelt pulleys offers significant advantages in energy efficiency. According to a report by the U.S. Department of Energy, optimizing mechanical systems with gearbelt pulleys can lead to efficiency gains of up to 30%, translating to substantial cost savings for manufacturers. These pulleys reduce energy loss through improved power transmission, minimizing friction and wear compared to traditional belt systems.

Additionally, a study conducted by the American Society of Mechanical Engineers (ASME) highlights that utilizing gearbelt pulleys can enhance the overall lifespan of machinery. By providing a more stable and precise motion transfer, these pulleys decrease the frequency of maintenance and downtime, which, as reported, can contribute to a 20% reduction in operational costs. As industries strive for sustainability and reduced operational expenditures, the adoption of gearbelt pulleys represents a smart investment that not only boosts productivity but also aligns with energy conservation goals.

| Application | Energy Efficiency Improvement (%) | Cost Savings ($/year) | Maintenance Reduction (%) | Operational Lifespan (months) |

|---|---|---|---|---|

| Conveyor Systems | 15% | $5,000 | 20% | 24 |

| Pumping Systems | 10% | $4,000 | 15% | 30 |

| Linear Actuators | 12% | $3,500 | 18% | 36 |

| Material Handling | 8% | $2,000 | 10% | 18 |

| Cooling Systems | 20% | $6,500 | 25% | 24 |

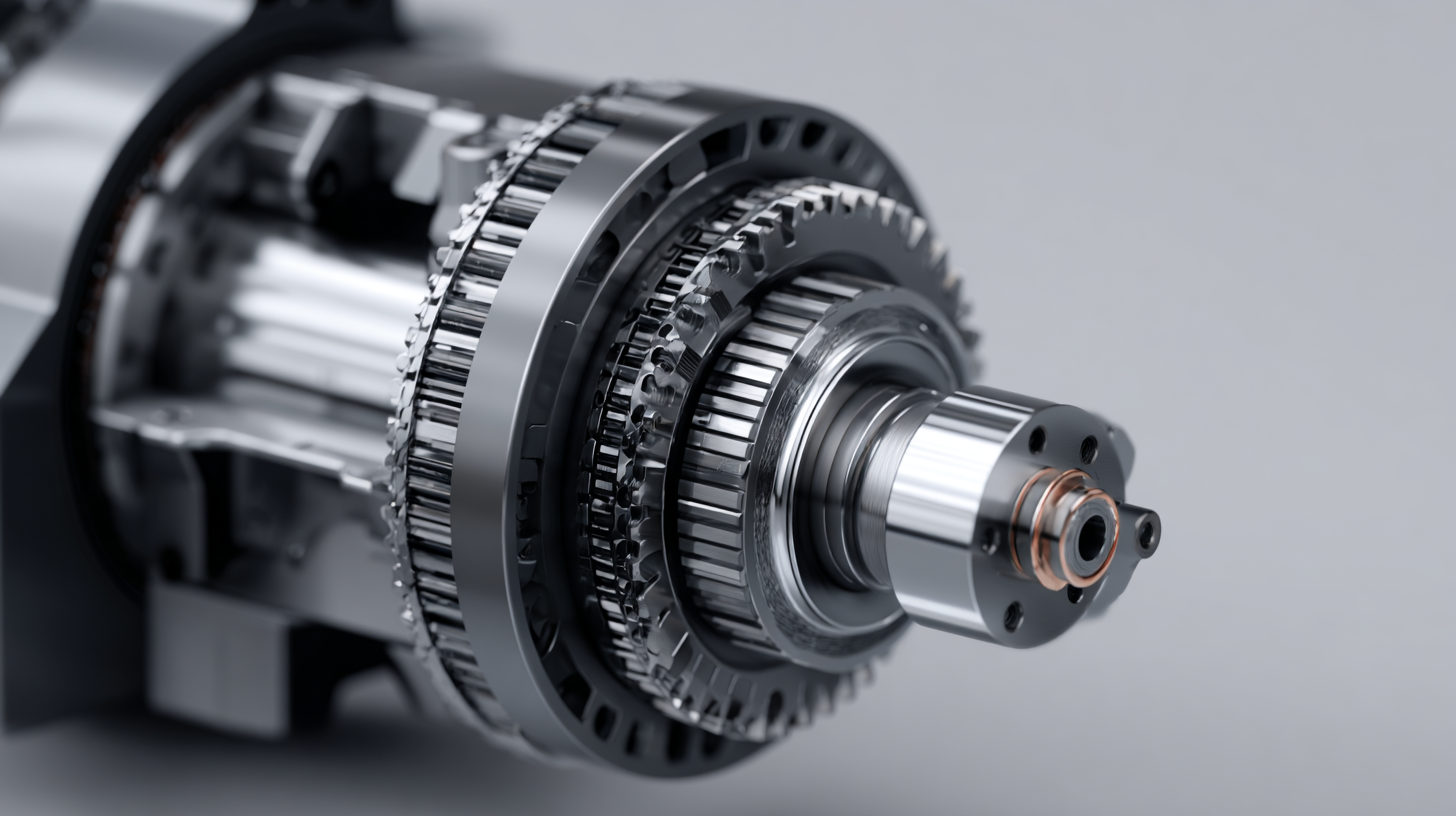

Advanced gearbelt pulleys are revolutionizing load management in mechanical systems by combining innovative designs with enhanced performance metrics. According to a report from the American Society of Mechanical Engineers, businesses utilizing modern pulley systems have seen a reduction in energy consumption by up to 20%, significantly lowering operational costs. These systems achieve such efficiency through optimized load distribution, allowing for smoother operation and reduced strain on other mechanical components.

Furthermore, the new pulley designs minimize wear and tear, which is vital for extending the lifespan of machinery. A study from the International Journal of Mechanical Engineering indicates that the integration of advanced materials in gearbelt pulleys decreases friction by over 30%, leading to less frequent maintenance and downtime. This improvement not only increases productivity but also enhances the reliability of mechanical systems in industries ranging from manufacturing to automotive, where performance is critical.

As gearbelt pulley technology continues to evolve, the potential for cost savings and efficiency gains will only expand, making them an essential component for future mechanical designs.

Gearbelt pulleys have emerged as a key component in optimizing mechanical systems across various industries. In a case study conducted by the Mechanical Engineering Journal in 2022, it was found that implementing gearbelt pulleys in manufacturing processes led to a staggering 25% increase in operational efficiency. This enhancement was attributed to the pulleys' ability to reduce friction and energy losses, allowing for smoother power transmission and less wear on machinery.

One notable success story comes from a well-known automotive manufacturer that integrated advanced gearbelt pulleys into their assembly lines. According to the 2023 Industry Report on Manufacturing Innovations, this transition resulted in a 30% reduction in downtime and a 20% increase in production speed. The use of high-performance gearbelt pulleys not only improved the overall efficacy of the system but also contributed to significant cost savings through reduced maintenance and increased reliability. These examples highlight the transformative impact gearbelt pulleys are having in real-world applications, further underscoring their importance in enhancing operational performance.