Leave Your Message

-

Phone

-

E-mail

In the world of mechanical engineering, choosing the right bevel gear can be a pivotal decision for the success of any project. As noted by renowned mechanical engineer Dr. Emily Carter, "The right bevel gear not only enhances performance but also prolongs the lifespan of your machinery." In 2025, with advancements in technology and an increasing variety of designs available, understanding the fundamentals of bevel gear selection has become more crucial than ever.

Bevel gears are essential components in machinery that allow for the transfer of power and motion between intersecting shafts. Their unique ability to change the axis of motion makes them invaluable in various applications, from automotive systems to industrial machinery. As engineers and designers face the challenge of optimizing performance while maintaining efficiency, the selection process can seem daunting. However, with the right guidelines and expertise, making an informed choice can lead to significant improvements in both functionality and reliability.

This guide aims to provide insights into the critical factors to consider when selecting bevel gears for your projects. By delving into aspects such as material selection, load capacity, and gear ratios, we aim to equip you with the knowledge needed to make the best decisions for your specific applications, ultimately ensuring the longevity and effectiveness of your engineering endeavors.

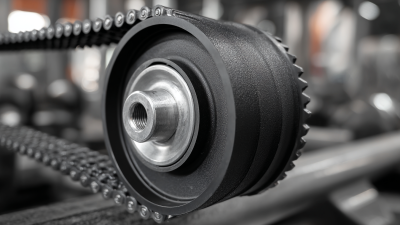

Bevel gears are essential components in machinery where the direction of rotation needs to be changed. They come in a variety of types, primarily including straight bevel gears, spiral bevel gears, and hypoid gears.

Straight bevel gears feature straight teeth and are primarily used in low-speed applications due to the significant noise and wear they can produce. Spiral bevel gears, with their angled teeth, offer smoother operation and are preferred in high-speed applications for their ability to distribute load more evenly. Hypoid gears, which can mesh at different axes, provide even greater strength and are often used in automotive and heavy machinery settings.

When choosing bevel gears for a project, it's crucial to consider their specific application, as each type offers distinct advantages. For instance, if precision and reduced noise are critical, spiral bevel gears would be ideal despite their slightly higher cost. In contrast, straight bevel gears may suffice for simple mechanical setups where noise is not a concern. Understanding the load capacity, speed requirements, and space constraints will significantly influence the decision-making process. Proper selection ensures not only efficiency but also the longevity of the system in which these gears are used.

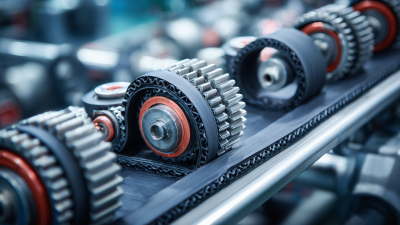

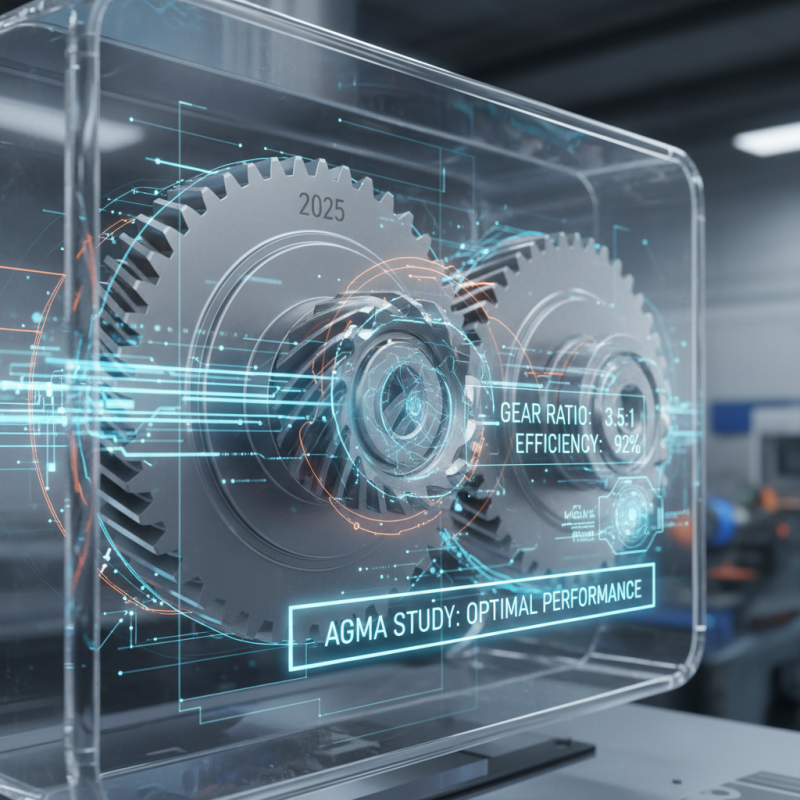

When selecting bevel gears for your project in 2025, several key factors must be carefully evaluated to ensure optimal performance and efficiency. One of the most critical considerations is the gear ratio, which directly influences the torque and speed of the machinery. A study by the American Gear Manufacturers Association (AGMA) suggests that an improper gear ratio can result in up to a 30% decrease in efficiency, leading to increased operational costs. Therefore, precise calculations and understanding the application's specific requirements are vital in determining the appropriate gear ratio.

Another essential factor to consider is the material and manufacturing quality of the bevel gears. Different applications may require gears made from various materials such as steel, brass, or polymers, depending on the load capacity and operating environment. According to a report by the International Federation of Robotics (IFR), advancements in gear manufacturing technologies, including precision machining and heat treatment processes, have significantly improved the performance and durability of bevel gears. Selecting high-quality materials can enhance wear resistance and significantly extend the lifespan of the gears, thereby reducing maintenance costs over time.

Finally, the alignment and mounting options of bevel gears are indispensable for achieving smooth operation. Misalignment can lead to excessive wear and premature failure, with studies indicating that misalignment can reduce gear life by as much as 50%. It's crucial to ensure proper installation and alignment during the setup phase. Considering these factors—gear ratio, material quality, and alignment—will guide you in making informed decisions and ultimately contribute to the success of your project.

When selecting the right material for bevel gears, it is crucial to consider factors such as load capacity, environmental conditions, and manufacturing processes. According to the "Gear Materials and Their Properties" report by the American Gear Manufacturers Association, different materials offer distinct advantages: carbon steels are commonly used for their strength and toughness, while alloys like chromium or nickel can enhance wear resistance and hardness. For applications requiring high performance under extreme conditions, materials such as titanium or specialized polymers may be beneficial, providing a balance between weight and strength.

Another key consideration is the gear's operational environment. Gears exposed to moisture, chemicals, or high temperatures may necessitate corrosion-resistant materials like stainless steel or advanced composites. A study published in the “Journal of Mechanical Engineering” indicates that selecting the appropriate material can lead to a significant reduction in failure rates, with well-chosen materials reducing maintenance costs by nearly 30%. Thus, comprehensive evaluations of mechanical properties, environmental resilience, and cost-effectiveness must guide the material selection process for bevel gears in any project.

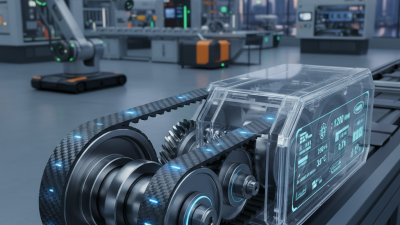

When selecting the right bevel gear for your project, understanding load and performance requirements is crucial. According to a comprehensive report by the Gears Manufacturing Association, approximately 30% of gear failures are attributed to inadequate load calculations. Thus, precise assessment of the mechanical load, including both static and dynamic conditions, is vital for ensuring reliability. Load calculations typically factor in gear ratios, torque, and operational speeds, often requiring the application of formulas such as the Lewis formula for bending strength or the Hertzian contact stress equations to analyze surface fatigue.

Performance requirements must also be evaluated to ensure optimal operation within the desired specifications. Key performance indicators include efficiency, backlash, and noise levels. Studies indicate that bevel gears operating at higher efficiency rates—typically above 95%—can significantly enhance the overall system performance. Moreover, considering the impact of environmental factors, as noted by the International Gear Association, selecting materials and coatings that withstand specific temperature ranges and resist corrosion can further amplify durability and effectiveness.

Therefore, comprehensive calculations and analyses can substantially influence the success of your bevel gear project, leading to enhanced performance and longevity.

When it comes to installing bevel gears, proper alignment is crucial for achieving optimal performance. Begin by ensuring that the shafts of the bevel gears are aligned correctly. Misalignment can lead to excessive wear and tear, noise, and ultimately, failure of the gears. Utilize alignment tools such as laser alignment systems or dial indicators to align the shafts accurately. Once aligned, secure the gear assembly firmly to prevent any movement during operation.

Maintenance is essential to prolonging the lifespan of bevel gears. Regularly inspect the gears for any signs of wear, such as pitting or scoring, which can indicate insufficient lubrication or misalignment. Ensuring proper lubrication is vital; use the manufacturer-recommended lubricants and maintain appropriate levels to minimize friction and heat generation. Additionally, create a maintenance schedule that includes periodic cleaning and re-lubrication, as well as checks for any unusual noises or vibrations that could signal a problem. By prioritizing installation and maintenance practices, you can enhance the reliability and efficiency of your bevel gear system.