Leave Your Message

-

Phone

-

E-mail

When embarking on a mechanical project, selecting the right timing pulleys is crucial. Renowned expert, Dr. Emily Carter, once stated, "The right timing pulleys can make or break your project's efficiency." This insight highlights the importance of making informed choices in this area.

Timing pulleys are not just components; they affect overall performance significantly. Choosing the wrong size can lead to serious misalignments. Too often, designers overlook the specifics of gear ratios and materials. Detailed calculations are necessary; they set the foundation for successful operation.

Failure to consider factors such as load capacity and environmental conditions can lead to frustrating setbacks. Understanding your project’s unique needs is vital. Testing and adjusting might be required along the way. Crafting a solid plan on this will enhance your project's success and efficiency.

Timing pulleys are integral components in many mechanical systems. Understanding their basics helps in selecting the right ones for your needs. Timing pulleys transfer motion with precision. They keep belts aligned, reducing slippage and improving efficiency.

In various industries, these pulleys find applications in robotics, conveyor systems, and automotive. A report by the Power Transmission Distributors Association indicates that the market for timing belts and pulleys is expected to grow at a CAGR of 6.5% through 2025. This growth highlights the importance of these components in modern engineering solutions.

When choosing timing pulleys, consider the tooth profile, pitch, and material. A mismatched tooth profile can cause noise and vibration. Each application has specific requirements. For instance, automotive applications may demand high durability, while robotics might prioritize lightweight materials. Evaluating these factors can prevent costly mistakes down the line.

When selecting timing pulleys for your project, several key factors come into play. The first consideration is the size of the pulleys. Their diameter will affect the speed ratio in your system. A smaller pulley can increase speed but may sacrifice torque. What is your project's requirement? Larger pulleys offer more torque at a slower speed, which is vital for certain applications.

Another important factor is the material used for the pulleys. Materials such as aluminum or plastic have their own advantages and disadvantages. Aluminum is durable but heavier. Plastic options are lightweight yet may wear out faster. Think about the environment your pulleys will operate in. Are they exposed to moisture or chemicals? This can impact your choice significantly.

Belt compatibility is also worth reflecting on. Timing pulleys must match the belt type you use. Misalignment can cause premature wear and efficiency loss. Ensure the tooth profile on pulleys aligns well with your belts. Sometimes, the perfect fit requires trial and error. Don't shy away from revisiting options if your initial choice doesn't perform as expected. Aim for a balance between performance and longevity. Evaluate your project needs carefully before making a final decision.

| Factor | Description | Recommended Range |

|---|---|---|

| Belt Type | The type of belt used can affect the choice of timing pulleys. | HTD, GT2, or RPP |

| Pitch | The distance between the teeth of the pulley. | 2mm - 20mm |

| Material | The material affects durability and performance. | Aluminum, Plastic, Steel |

| Load Capacity | The maximum load the pulley can handle. | Up to 500 kg |

| Diameter | The outer diameter of the pulley, affecting speed and torque. | 20mm - 200mm |

| Number of Teeth | More teeth can mean smoother operation but changes gear ratio. | 10 - 100 |

| Backlash | The clearance between the teeth for precise movement. | Minimal, ideally less than 0.5mm |

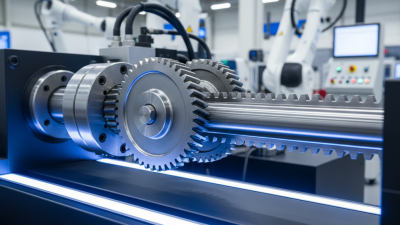

When selecting timing pulleys, understanding the differences is crucial. There are several types, including poly-V and toothed pulleys. Each has unique benefits that suit specific applications.

Poly-V pulleys are ideal for compact designs. They offer high power transmission in confined spaces. This can be an advantage or a limitation, depending on your project needs.

Toothed pulleys, on the other hand, provide precise timing and synchronization. They help prevent slippage, essential in machinery requiring high accuracy. However, the choice isn’t straightforward.

Toothed designs can wear out faster under heavy loads. This may necessitate more frequent replacements, affecting long-term costs.

Carefully consider these factors when making your selection. Understanding your project's specific requirements will lead you to the best option.

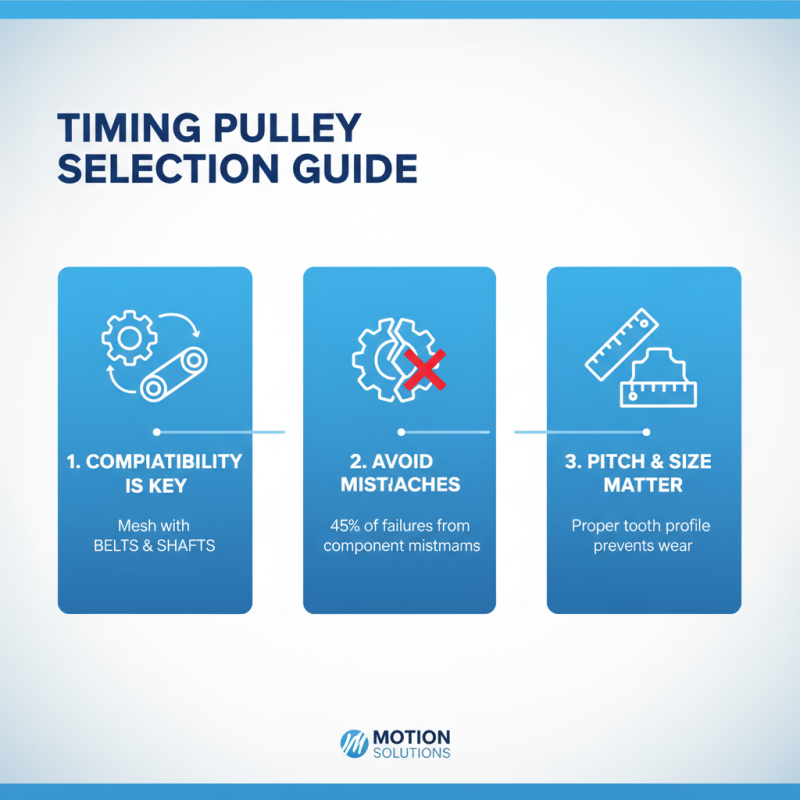

When selecting timing pulleys for a project, compatibility with existing components is crucial. In a well-designed system, timing pulleys must mesh smoothly with belts and shafts. According to a report by the Motion Control Association, 45% of mechanical failures are linked to component mismatches. Identifying the right pitch and size is essential. For instance, using a pulley with an improper tooth profile can lead to excessive wear.

Designers often overlook the importance of load capacity. Pulleys should withstand the system's forces without failure. A study by the American Society of Mechanical Engineers highlights that 30% of design errors stem from miscalculating these loads. Moreover, the material selection of the pulleys affects their longevity and performance. Plastic may be less durable than metal in high-stress environments, but it is lighter and less expensive.

Compatibility also extends to shaft diameters and mounting configurations. A slight misalignment can lead to operational issues. In a survey by the National Fluid Power Association, 25% of engineers admitted they underestimated the impact of integration. Adjustments often require additional resources and time, which could lead to project delays. Keeping all these factors in mind can streamline the selection process and enhance overall system performance.

When selecting timing pulleys, proper sizing is crucial. The right size enhances performance and improves efficiency. A pulley that is too large or too small can lead to mechanical issues. This can cause premature wear or system failure. To ensure a good fit, measure the corresponding belt accurately. Use calipers to get precise dimensions. Small discrepancies can result in poor engagement.

Tip: Always verify the pulley diameter and the number of teeth. This impacts speed ratios, torque, and load capacity. An incorrect ratio affects performance. Checking these details prevents later adjustments.

Consider the material of the pulleys as well. Materials like nylon or aluminum each have unique strengths and weaknesses. Nylon is lightweight, but aluminum offers better durability. Depending on the project, one may suit you more than the other.

Tip: Evaluate your project's environment. Will pulleys be exposed to moisture or heat? This can influence material choice and overall longevity. Be aware of your project’s specific demands for optimal results.