Leave Your Message

-

Phone

-

E-mail

Choosing the right machinery belts is critical for operational efficiency. In the machinery industry, the failure rate of improperly selected belts is alarming. According to a recent report by Market Research Future, nearly 30% of machinery downtime is attributed to unsuitable belt choices.

Expert in industrial equipment, John Anderson, states, “Selecting the correct machinery belts is essential for maximizing productivity.” He emphasizes that the wrong belt can lead to increased wear and system failures. In many cases, businesses overlook crucial specifications, such as load capacity and temperature resistance. As a result, costly mistakes happen.

Investing time to understand different belt types pays off. The variety of materials and designs can impact performance drastically. Many companies experience challenges in adapting their machinery to new technologies. Taking a closer look at machinery belts can reveal hidden inefficiencies.

When selecting machinery belts for your equipment, several factors must be considered. The type of material is crucial. Different belts use various raw materials, impacting their durability and flexibility. Synthetic materials might offer better resistance to wear and environmental factors. However, natural rubber can provide superior grip in some applications. It’s essential to match the belt material with your operational conditions.

Another vital aspect is the belt size. The wrong size can lead to inefficiency and premature failure. Measure the pulley diameter and ensure that you’re choosing the correct length and width. This may seem straightforward, but it’s a common oversight that can lead to costly downtime. Additionally, consider the load capacity. Belts designed for higher loads must be chosen if your machinery operates under stress. Failing to account for this can result in unexpected breakdowns.

Lastly, think about the operating environment. Factors like temperature and exposure to chemicals can affect belt performance. A belt that works well in a cool, clean setting might struggle in a hot, oily one. It's worth reflecting on past experiences; analyzing previous failures can guide better decisions. Choosing the right belt requires thorough research and attention to detail. It's an imperfect process, but learning from it can significantly improve your long-term equipment efficiency.

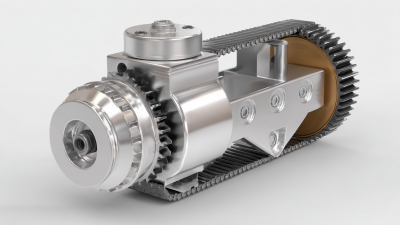

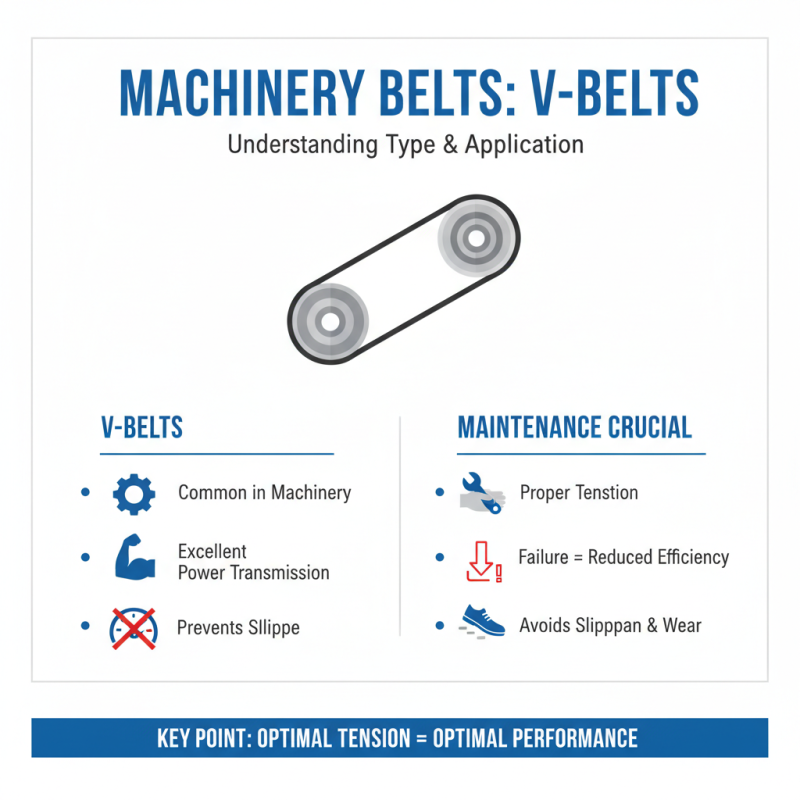

When selecting machinery belts, it's essential to understand their different types and applications. V-belts are commonly used in various machinery setups. They provide excellent power transmission. However, maintaining proper tension is crucial. Failure to do so can lead to slippage or reduced efficiency.

Flat belts, on the other hand, are perfect for light-duty applications. They often run on flat pulleys. This design makes them suitable for situations where flexibility is vital. Yet, their effectiveness can be hindered by heat and wear. Regular inspections are necessary to ensure optimal performance.

Timing belts are essential for applications needing precise synchronization. They prevent slippage and maintain alignment between components. While these belts are robust, they require proper installation to avoid problems later. Regular monitoring can help reduce unexpected failures. Understanding these nuances helps in selecting the right belt for your machinery.

When selecting machinery belts, evaluating load capacity and performance ratings is essential. Load capacity refers to the maximum weight a belt can handle without failure. It is crucial to match this capacity to your equipment's requirements. If a belt is too weak, it may wear out quickly or break during operation.

Performance ratings provide insight into a belt's durability and efficiency. Look for specifications that detail factors like tensile strength, elongation, and resistance to wear. Consider environments where belts will be used. High temperatures or exposure to chemicals may require belts with specific ratings.

Tips: Assess your operational demands before choosing a belt. Understand the working conditions that your machinery faces daily. Pay attention to any signs of wear or performance dips in your current belts. Regular evaluations will help you make informed decisions. Don’t overlook the importance of compatibility with your machinery. A well-matched belt increases efficiency and reduces unexpected breakdowns.

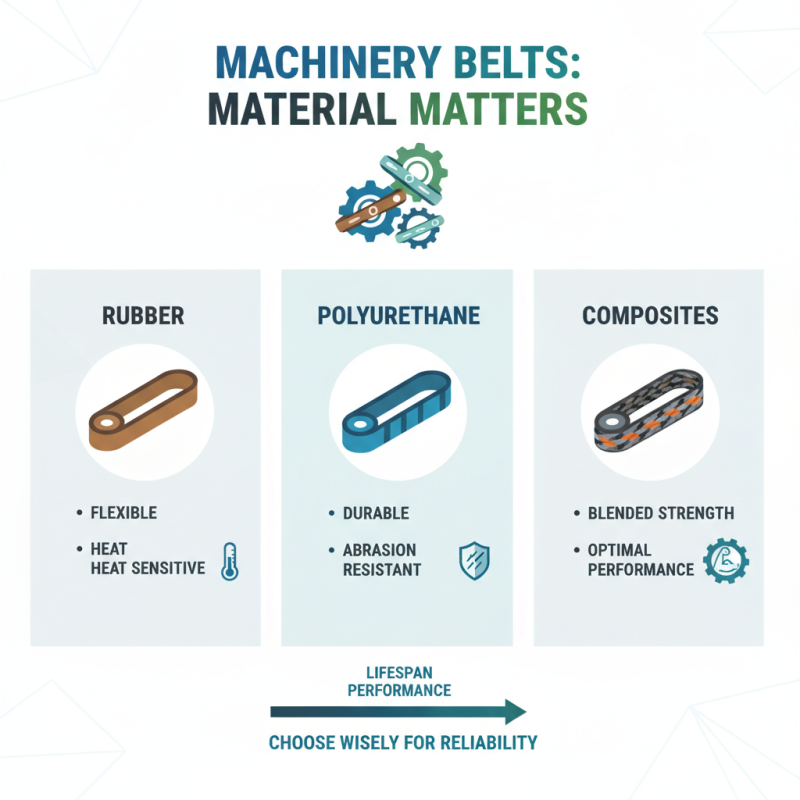

Selecting the appropriate machinery belts relies heavily on material composition. The durability of these belts is vital for optimal performance. Common materials include rubber, polyurethane, and composites. Each material brings unique properties to the table. For instance, rubber offers flexibility but may wear out quicker under heat. Polyurethane is tougher and resists abrasions better.

It's essential to consider operating conditions too. High temperatures can degrade certain materials. In contrast, some might struggle in cold environments. If the belt isn't suited for the application, frequent replacements may occur. This can lead to unforeseen downtime and added costs.

A belt's performance is not just about its initial strength. Over time, factors like exposure to chemicals and UV light can weaken its integrity. Regular inspections can help identify wear and potential failures. However, understanding the specific needs of your machinery remains crucial. Choosing a belt based solely on price can lead to regrettable choices. Reassessing material options could result in longer-lasting solutions.

When it comes to selecting machinery belts, environmental conditions play a crucial role. Temperature, humidity, and exposure to chemicals can significantly impact belt performance. For instance, a high-humidity environment may lead to quicker wear and tear. Belts that are not compatible with moisture may slip or stretch excessively.

Tips: Always assess your facility's conditions. Take notes on temperature fluctuations. Watch for any signs of corrosion or deterioration around machinery.

Another factor is the presence of contaminants. Dust and dirt can accumulate, making it essential to choose belts resistant to such particles. In a dusty workshop, regular cleaning might only delay the inevitable. Consider belts designed for harsh environments. They are often more resilient.

Tips: Implement a routine inspection of belts. Look for visible signs of wear and contamination. Replace belts that show early signs of fatigue.

Lastly, consider vibration levels in your machinery. Equipment that vibrates excessively can cause belts to misalign. Choosing the right tension is key. An over-tensioned belt can fail prematurely, while a loose one may slip.

Tips: Adjust tension settings according to your machinery's needs. Keep a close eye on the performance. Don’t overlook small adjustments—they matter.

| Belt Type | Material | Temperature Range | Humidity Resistance | Chemical Resistance | Load Capacity |

|---|---|---|---|---|---|

| V-Belt | Rubber | -30°C to 80°C | Moderate | Low | High |

| Flat Belt | Polyester | -20°C to 70°C | High | Moderate | Moderate |

| Timing Belt | Neoprene | -20°C to 100°C | Low | High | High |

| Round Belt | Polyurethane | -10°C to 60°C | Very High | Moderate | Low |

| Cogged Belt | Rubber | -30°C to 75°C | Moderate | Low | High |