Leave Your Message

-

Phone

-

E-mail

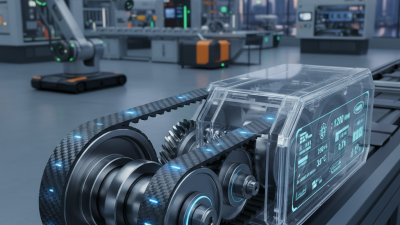

In the ever-evolving landscape of industrial manufacturing, the choice of components significantly influences operational efficiency and productivity. Among these components, the Endless Flat Belt has emerged as a crucial player in various applications such as material handling, packaging, and automation systems. According to a recent report by MarketsandMarkets, the global conveyor belt market is projected to reach USD 7.6 billion by 2025, driven by the increasing demand across industries like food and beverage, mining, and logistics. This underscores the critical role that Endless Flat Belts play in streamlining processes and enhancing throughput.

Choosing the best Endless Flat Belt for your specific industrial needs requires careful consideration of several factors, including material composition, width, thickness, and operational environment. Research by Technavio indicates that variations in belt design and strength can significantly impact the longevity and reliability of industrial operations. With the right choice of an Endless Flat Belt, manufacturers can achieve substantial reductions in downtime and maintenance costs while improving overall productivity. This article aims to guide you through the essential criteria for selecting the perfect Endless Flat Belt, ensuring that your operations run smoothly and efficiently.

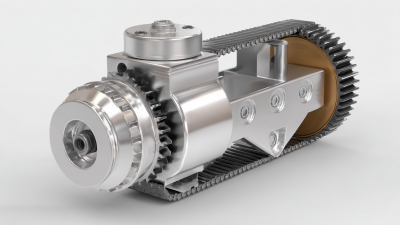

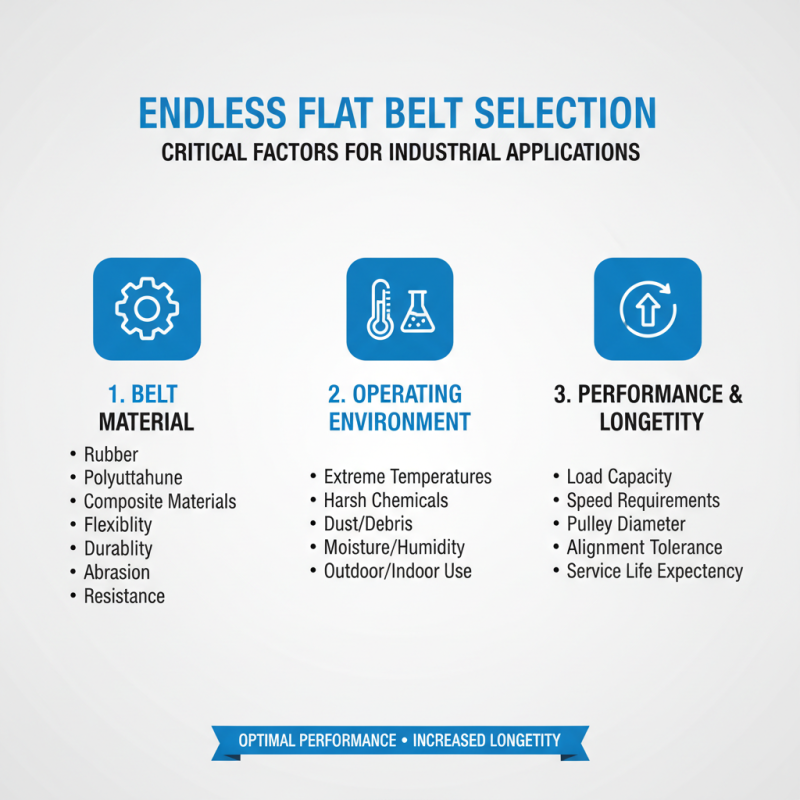

When selecting endless flat belts for industrial applications, several critical factors must be considered to ensure optimal performance and longevity. Firstly, it's essential to assess the material used in the belt's construction. Common materials include rubber, polyurethane, and composite materials, each offering different levels of flexibility, durability, and resistance to abrasion. The operating environment also plays a significant role; for instance, belts exposed to extreme temperatures or harsh chemicals must have specific properties to withstand such conditions without degrading.

Another important factor is the belt's width and thickness, which should align with the intended load and the type of machinery it will be used with. A belt that is too thin may not support the required load, leading to premature wear, while an overly thick belt could create unnecessary friction, resulting in energy inefficiency. Additionally, the belt's tensile strength is crucial, especially for heavy-duty applications, as it determines how much force the belt can handle without breaking. Ultimately, careful consideration of these factors will help in selecting an endless flat belt that meets both operational and safety standards for industrial needs.

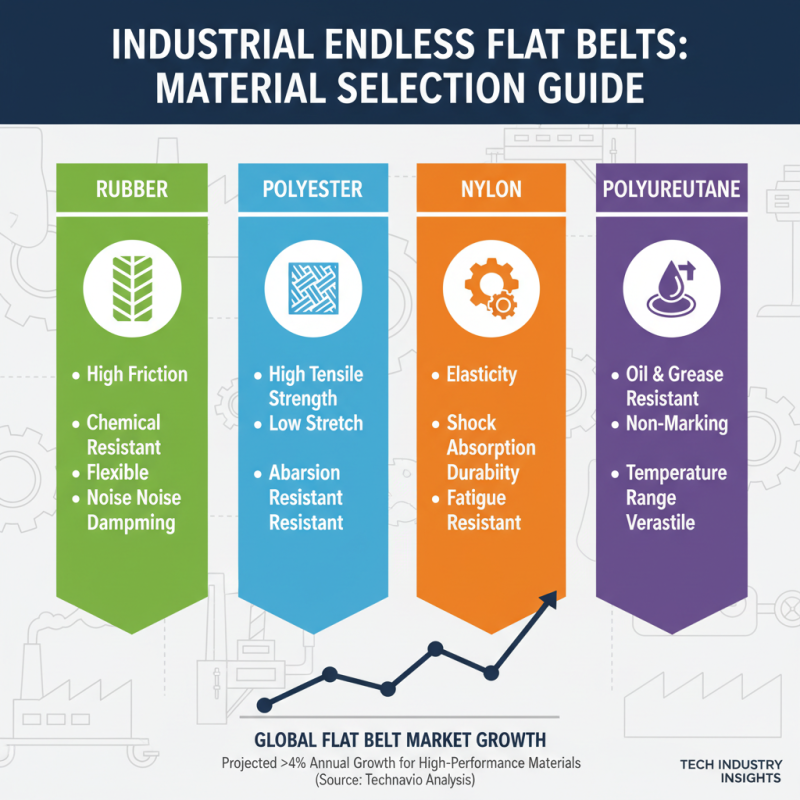

When selecting the best endless flat belt for industrial applications, understanding the various materials available is crucial. Endless flat belts are predominantly made from materials such as rubber, polyester, nylon, and polyurethane, each offering distinct advantages based on the specific operational requirements. According to a recent market analysis by Technavio, the global flat belt market is projected to grow significantly, with the demand for high-performance materials increasing by over 4% annually. This underscores the importance of choosing the right material that not only enhances performance but also increases durability and efficiency.

Rubber belts, for instance, are widely used due to their excellent grip and flexibility. They can handle varying temperatures and are resistant to abrasion, making them suitable for heavy-duty applications. In contrast, polyester belts are known for their strength and resistance to stretching and shrinking, which is ideal for precise operations in conveyor systems. Furthermore, polyurethane materials have emerged as a popular choice owing to their superior wear resistance and ability to perform in extreme conditions, often showing a significant reduction in downtime for maintenance. Understanding these material properties enables industries to make informed decisions that optimize their production processes and reduce operational costs.

When selecting the appropriate width and length for an endless flat belt in industrial applications, it is crucial to align these dimensions with the specific requirements of your operation. According to industry data from the Conveyor Equipment Manufacturers Association (CEMA), the width of a flat belt should be determined based on the load capacity and the type of materials being transported. For instance, a belt width of 24 inches is typically suitable for lighter loads, while a width of 36 inches or more may be necessary for heavier loads or bulk materials. Moreover, it's recommended to utilize a belt width that allows for efficient material transfer without excessive side friction, which can lead to quicker wear and increased maintenance costs.

Length considerations must also reflect the application's needs, particularly for effective power transmission and optimized speed control. A report from the International Material Handling Research Institute highlights that belt length should encompass all necessary routes and inclines, incorporating a certain percentage of tension for mechanical efficiency. A calculated length allows for the flexibility needed during operation while ensuring that the belt is not excessively long as that can lead to slack and impact performance. Ultimately, precise measurement and understanding of your load dynamics are essential to determine the best width and length for your endless flat belt, ensuring longevity and effectiveness in your industrial needs.

| Belt Type | Width (mm) | Length (m) | Material | Load Capacity (kg) | Temperature Range (°C) |

|---|---|---|---|---|---|

| Polyester | 50 | 10 | Textile | 100 | -20 to 80 |

| Nylon | 100 | 12 | Synthetic | 150 | -10 to 90 |

| Rubber | 75 | 15 | Natural | 200 | -20 to 60 |

| Polyurethane | 120 | 8 | Thermoplastic | 180 | -30 to 70 |

| Leather | 60 | 20 | Natural | 80 | -10 to 50 |

When selecting the best endless flat belt for industrial applications, it is crucial to evaluate the operating conditions that will affect the belt's performance.

Temperature is one of the primary factors to consider, as different materials used in belt construction have varying thermal resistance. If the operational environment involves extreme heat or cold, the selected belt should be capable of maintaining its integrity and effectiveness under those conditions.

High temperatures may cause certain materials to warp or degrade, while excessively low temperatures can make others brittle, both of which would lead to premature failure.

Load and speed requirements also play a significant role in the selection process. The belt must be designed to handle the specific loads it will encounter during its operation, whether they be heavy or light.

Load capacity will determine the thickness and material of the belt, ensuring it can sustain operational demands without risk of breaking or wearing out quickly.

Additionally, the speed at which the belt will operate affects the choice of material and construction; higher speeds might require belts with reinforced structures to prevent slippage and vibration, ensuring smooth and efficient operation.

Carefully considering these factors will lead to a well-suited endless flat belt that meets your industrial needs effectively.

When selecting an endless flat belt for industrial applications, understanding the balance between cost and efficiency is essential. Industry reports indicate that inefficiencies in conveyor systems can lead to operational costs increasing by up to 30% annually. Therefore, opting for a high-quality belt that offers durable performance can lead to significant long-term savings. According to a recent study by the Association for Manufacturing Technology (AMT), investing in more efficient belting solutions can yield about 20% more throughput in manufacturing processes, thereby offsetting the initial purchase costs over time.

Moreover, the type of material used in the belt construction directly impacts both its efficiency and cost. For example, belts made from polyurethane tend to offer superior flexibility and wear resistance, which can reduce downtime caused by maintenance needs. A report from the Conveyor Equipment Manufacturers Association (CEMA) highlights that companies that switch to high-efficiency belts experience an average reduction in energy consumption by approximately 15%. This reduction in energy use not only translates to direct cost savings but also contributes to a company’s sustainability goals. Investing in the right endless flat belt is not merely a matter of upfront costs; it is about choosing a solution that ensures optimal operational efficiency and profitability.