Leave Your Message

-

Phone

-

E-mail

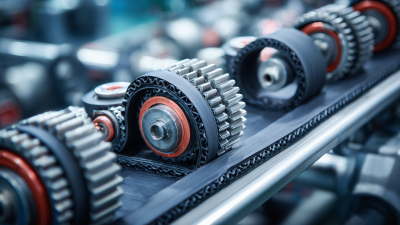

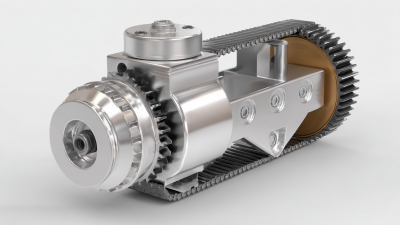

When selecting components for a mechanical project, one critical decision lies in choosing the right pulleys. Among the various materials available, Aluminum Timing Belt Pulleys stand out due to their unique combination of strength, lightweight properties, and resistance to wear and corrosion. This makes them an ideal choice for applications ranging from robotics to automotive systems, where precision and reliability are paramount.

However, with so many options available on the market, it can be overwhelming to determine which aluminum timing belt pulleys best suit your specific needs. Factors such as pulley size, tooth profile, and load capacity must be carefully considered to ensure optimal performance. Additionally, understanding the different manufacturing processes and finishes can help you find durable and efficient pulleys that enhance the overall functionality of your project.

In this guide, we will explore essential considerations and best practices for selecting aluminum timing belt pulleys, ensuring that you make an informed choice tailored to your project’s requirements. By taking the time to understand these critical elements, you can enhance the reliability and efficiency of your mechanical systems.

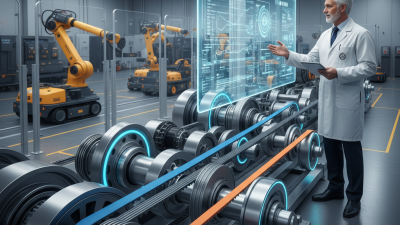

Aluminum timing belt pulleys play an essential role in mechanical systems, serving as a crucial interface between the timing belt and the engine or machine components. Their lightweight nature and high strength contribute to improved efficiency and performance in various applications, from automotive engines to industrial machinery. According to recent industry reports, the use of aluminum pulleys can reduce overall weight by approximately 20% compared to traditional steel options, leading to lower energy consumption and enhanced power-to-weight ratios in high-performance scenarios.

In modern mechanical design, replacing outdated V-belt systems with advanced serpentine setups can yield significant benefits. Serpentine belt systems, which require fewer pulleys and can handle higher loads, are becoming increasingly popular for their durability and aesthetic appeal. The streamlined design not only optimizes engine space but also minimizes friction, which can lead to an impressive reduction in maintenance requirements and operational costs. As manufacturers strive to improve the efficiency of their mechanical systems, selecting the right aluminum timing belt pulleys becomes critical in harnessing these advancements while ensuring compatibility with new serpentine drive configurations.

| Pulley Size (Diameter) | Belt Type | Number of Teeth | Material Type | Weight (grams) | Max RPM |

|---|---|---|---|---|---|

| 30 mm | GT2 | 20 | Aluminum 6061 | 15 | 8000 |

| 40 mm | GT2 | 24 | Aluminum 7075 | 20 | 7000 |

| 50 mm | HTD | 30 | Aluminum 6061 | 25 | 6000 |

| 60 mm | HTD | 36 | Aluminum 7075 | 30 | 5000 |

When selecting aluminum timing belt pulleys for your project, several key factors should be prioritized to ensure optimal performance and compatibility. First, consider the size and pitch of the timing belt. Pulleys must match the specific belt's tooth profile and pitch to function correctly and maintain alignment in the system. It's important to measure the distance between the pulleys accurately and account for the application's torque requirements to avoid slippage or premature wear.

Another vital aspect is the pulley design and material quality. Aluminum offers a perfect balance between weight and strength, making it a popular choice for various applications. Look for pulleys that feature an anodized finish for enhanced durability and corrosion resistance. Additionally, evaluate the pulley’s tooth count and shape, as these elements influence the gearbox ratio and system efficiency. By carefully assessing these factors, you can choose the best aluminum timing belt pulleys that meet your project's specifications and performance needs.

When selecting aluminum timing belt pulleys for your project, it's essential to compare the different types available to ensure optimal performance and efficiency. Aluminum pulleys are favored for their lightweight yet robust construction, making them suitable for high-speed applications. The most common types include standard pulleys, flanged pulleys, and timing pulleys, each serving distinct purposes. Standard pulleys provide a straightforward solution for basic timing needs, while flanged pulleys offer added stability, preventing the belt from slipping off during operation.

Another crucial aspect to consider is the tooth profile and pitch of the pulley. Different pulley designs can affect the engagement with the timing belt, impacting the overall efficiency of power transmission. It's also important to assess the finish of the aluminum, as anodized options provide enhanced durability and resistance to wear and corrosion. By carefully comparing these features and understanding the specific requirements of your project, you can make a well-informed decision that will enhance the performance and longevity of your mechanical system.

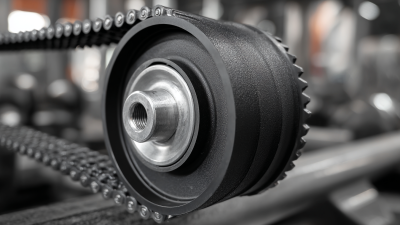

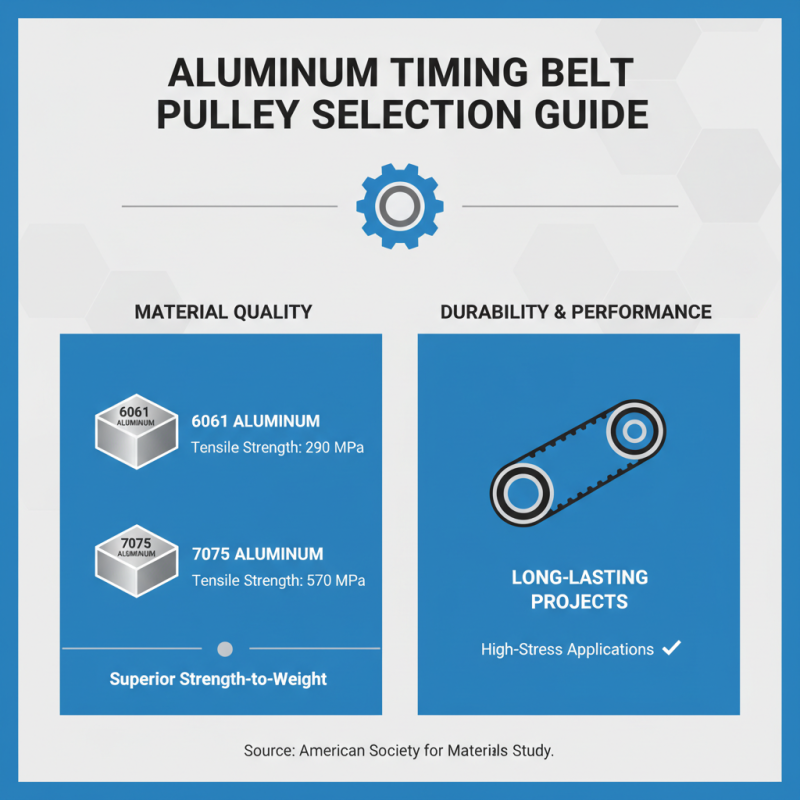

When selecting aluminum timing belt pulleys, evaluating their quality and durability is paramount to ensure long-lasting performance in any project. High-quality pulleys often showcase superior materials, typically composed of 6061 or 7075 aluminum, which are known for their excellent strength-to-weight ratios. A study conducted by the American Society for Materials shows that 6061 provides an average tensile strength of 290 MPa, while 7075 can reach up to 570 MPa, making them suitable for high-stress applications.

In addition to the material, manufacturing processes play a critical role in the durability of these pulleys. Precision machining techniques, such as CNC milling, can enhance the accuracy and fit of the pulleys, thereby reducing the risk of wear and failure over time. According to a report by the International Journal of Advanced Manufacturing Technology, precision-engineered components can reduce operational failure rates by up to 30%. Investing in pulleys with robust surface treatments, such as anodizing, can also significantly improve corrosion resistance and longevity, which is crucial in environments exposed to moisture or chemicals. Careful consideration of these factors will ensure that your aluminum timing belt pulleys perform reliably and effectively throughout their intended lifespan.

Aluminum timing belt pulleys are widely utilized in various mechanical and engineering projects due to their lightweight and high strength characteristics. Common applications include robotics, where they contribute to precise movement in automated systems. According to a report from the Association for Manufacturing Technology, the use of aluminum components in robotics has grown by approximately 15% annually, largely attributed to their ability to reduce overall weight while maintaining structural integrity. This makes them ideal for applications that require agility and speed, such as in robotic arms and conveyance systems.

In the automotive industry, aluminum timing belt pulleys find their place in engine systems to manage timing with precision. The International Journal of Automotive Engineering has highlighted that the implementation of lightweight materials like aluminum can reduce engine weight by up to 10%, enhancing performance and fuel efficiency. Additionally, in CNC machinery, aluminum pulleys are preferred for their wear resistance and smooth operation, contributing to enhanced machining accuracy and extended tool life. This diverse utility underscores the importance of selecting the right aluminum timing belt pulley for specific project needs, ensuring both performance and efficiency are optimized.