Leave Your Message

-

Phone

-

E-mail

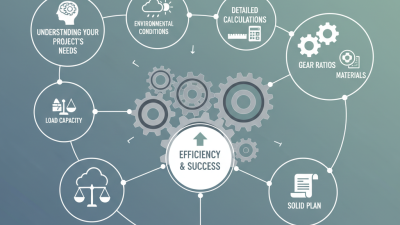

In the world of mechanical engineering, Taper Lock Gear plays a critical role in enhancing performance and ensuring durability. Renowned expert Dr. James Miller, a leading figure in gear technology, once stated, "The precision of Taper Lock Gears can significantly impact machine efficiency." His insights shed light on the importance of selecting the right gear type.

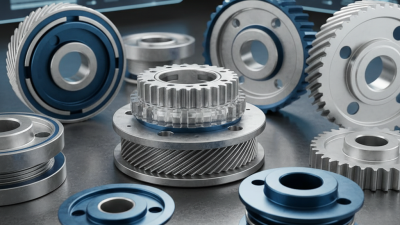

Taper Lock Gears offer unique advantages. They provide easy installation and maintenance. These gears reduce downtime, which is crucial in production environments. Yet, not all Taper Lock options are created equal. The range of quality can lead to confusion. It’s essential to evaluate each gear's specifications carefully.

Some users may overlook the potential for wear and tear over time. Ignoring maintenance schedules can lead to serious issues. As Dr. Miller noted, the impact of ill-fitted gears can cascade, affecting overall machinery performance. Thus, the right choice among the best Taper Lock Gear options is vital. It ensures enhanced efficiency and longevity, promoting a more robust operation.

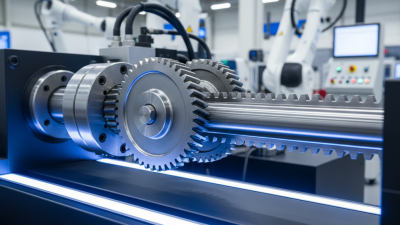

In industrial applications, taper lock gears play a crucial role. They ease the installation process and significantly reduce downtime. According to industry research, over 60% of mechanical failures are due to improper gear mounting. Taper lock designs offer better alignment and enhanced performance. They accommodate variations in shaft sizes, making them versatile.

Moreover, taper lock gears exhibit impressive durability. Reports indicate that these gears can withstand high torque loads without significant wear. This quality is essential in heavy machinery, where reliability is critical. Misalignments can lead to catastrophic failures. The unique locking mechanism of taper lock gears prevents slippage, ensuring consistent operation.

However, not all taper lock options are created equal. Some may not fit properly, leading to performance issues. Regular maintenance is critical to avoid such pitfalls. While these gears offer many benefits, users must be diligent about their choices. Investing in quality taper locks can lead to long-term savings and fewer complications in the production line. Proper awareness and reflection on their use can elevate industrial efficiency.

When selecting taper lock gears, performance and durability are paramount. Look for materials that withstand wear and tear. High-carbon steel and alloyed materials are often recommended. They provide excellent strength while enhancing lifespan. According to industry reports, using appropriate materials can increase gear life by up to 30%.

Precision is critical in manufacturing taper lock gears. Opt for gears produced with advanced machining tools. Tolerances of 0.001 inches are common in high-performance options. This precision ensures a better fit and reduces vibration, which can lead to premature failure. It's noted that misalignment can reduce efficiency by up to 20%.

Consider the design features as well. Profile designs that minimize backlash improve performance significantly. Some experts suggest that gears with optimized tooth geometry can enhance load distribution. This can lead to improved torque handling. However, achieving this level of design requires a balance, as complex geometries can sometimes increase production costs. Acknowledging these trade-offs is critical for making informed decisions.

Taper lock gears are crucial in various applications. Understanding the materials used for these gears can enhance their performance and durability. Common materials include steel, aluminum, and plastic. Each material has its own advantages and drawbacks.

Steel gears offer incredible strength and resistance to wear. However, they can be heavy and may corrode over time. Aluminum provides a lighter alternative but may not match steel's durability in high-stress situations. Plastic gears are lightweight and resistant to corrosion; yet, they may wear out quicker under heavy loads.

**Tip:** Always consider the specific application when choosing gear materials. For longevity, ensure the gears are properly lubricated.

Additionally, testing different options can lead to better performance. Sometimes, finding the balance between weight and strength is tricky. Observing actual gear performance can guide future choices.

**Tip:** Regularly inspect your gear systems for signs of wear. Early detection can prevent larger issues down the road.

Taper lock gears are essential for applications needing enhanced efficiency and longevity. According to industry reports, using proper taper locks can improve mechanical performance by 20%. They provide secure connections and minimize wear. This boosts the overall lifespan of machinery.

**Tips:** Choose gears made with high-quality materials. This reduces friction and can lead to better durability. Regular inspections are important. Small wear may escalate if overlooked. Keeping an eye on performance can save costs.

Incorporating taper lock gears also helps simplify maintenance. They are easier to replace or adjust compared to traditional methods. This can lead to significant downtime reductions. Reports suggest businesses that employ these options see up to a 15% increase in productivity. However, over-reliance on these systems without regular evaluation can lead to unforeseen issues. Balancing usage with preventive care is crucial for optimal results.

| Taper Lock Option | Material | Load Capacity (lbs) | Efficiency (%) | Longevity (Hours) |

|---|---|---|---|---|

| Model A | Steel | 1500 | 95 | 2000 |

| Model B | Aluminum | 1200 | 90 | 1800 |

| Model C | Bronze | 1300 | 92 | 1500 |

| Model D | Plastic | 1000 | 85 | 1200 |

| Model E | Composite | 1600 | 94 | 2200 |

| Model F | Titanium | 1100 | 89 | 1600 |

| Model G | Carbon Steel | 1400 | 91 | 1900 |

| Model H | Stainless Steel | 1700 | 97 | 2500 |

| Model I | Nickel Alloy | 1800 | 96 | 3000 |

| Model J | Zinc Alloy | 900 | 80 | 1000 |

When selecting taper lock gears, understanding industry standards and certifications is crucial. These guidelines ensure products meet specific performance requirements. The American National Standards Institute (ANSI) establishes metrics for gear tolerances and dimensions. According to a 2022 report by the Gear Research Society, adhering to ANSI standards can increase gear life by 20%.

Furthermore, ISO 9001 certification signifies a commitment to quality management systems. Companies with this certification often achieve better consistency in manufacturing. A study from a leading engineering journal revealed that certified manufacturers have a 15% lower failure rate compared to non-certified competitors.

It's essential to note that even with stringent standards, not all gears perform equally. Variables like material quality and manufacturing methods can influence performance. Some gears may initially seem robust but fail prematurely in specific applications. Therefore, a thorough assessment of both standards and individual product performance is necessary for optimal gear selection.