Leave Your Message

-

Phone

-

E-mail

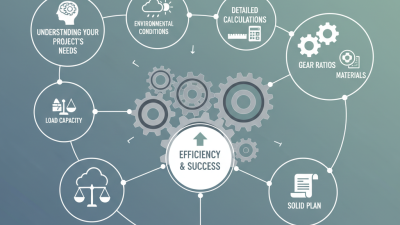

When embarking on a project that requires power transmission, choosing the right components is crucial. One of the essential components in this realm is the Round Belt Pulley. With various options available, it’s important to know the features that suit your specific needs. This article explores the best Round Belt Pulley options, emphasizing their practicality in different scenarios.

Round Belt Pulleys come in various sizes and materials. Each variation offers distinct advantages. For example, some are designed for high torque applications, while others excel in precision systems. Understanding these differences can greatly impact project success. Yet, some may struggle to choose the right type for their requirements.

Consider the environment where the pulley will operate. Factors like temperature and humidity can influence the material choice. It's a common mistake to overlook these details, which can lead to installation failures. Thus, this guide aims to provide clarity and help make informed decisions in your next project. Choosing wisely today can save headaches tomorrow.

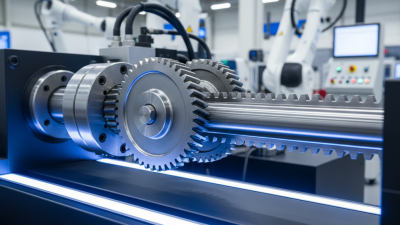

Round belt pulleys play a crucial role in various mechanical systems. They provide a reliable means of transferring power from a motor to different components. With the right pulley, efficiency improves significantly. This is essential in manufacturing and other sectors where precision and reliability matter. The material of a pulley can greatly influence its performance. For example, the right composition can reduce wear and enhance longevity.

Selecting the appropriate round belt pulley involves careful consideration. Overlooked details can lead to inefficiencies. A miscalculated size may result in slippage or increased friction. This can severely affect overall system performance. Proper tensioning of the belt is equally vital. Too much tension can wear out components quickly, while too little can cause slipping.

One common challenge is finding the right fit for specific project needs. The market offers numerous options, each with unique specifications. Not all pulleys are compatible with every type of belt. Errors can lead to increased downtime and repairs. Testing different materials and dimensions can yield unexpected results. It is essential to analyze performance data and adjust accordingly. Each project may require a unique approach to achieve the best results.

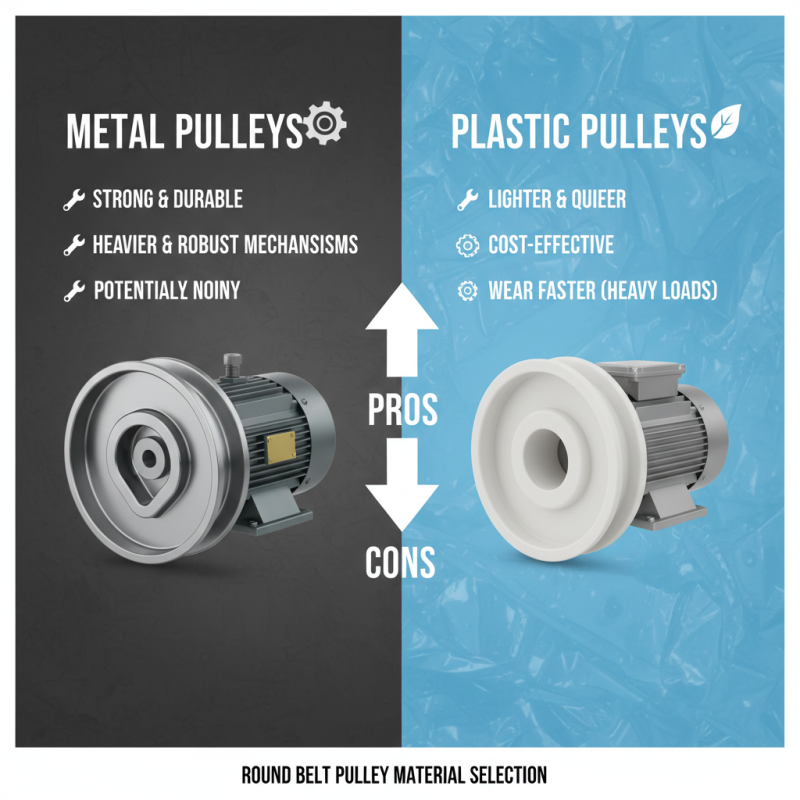

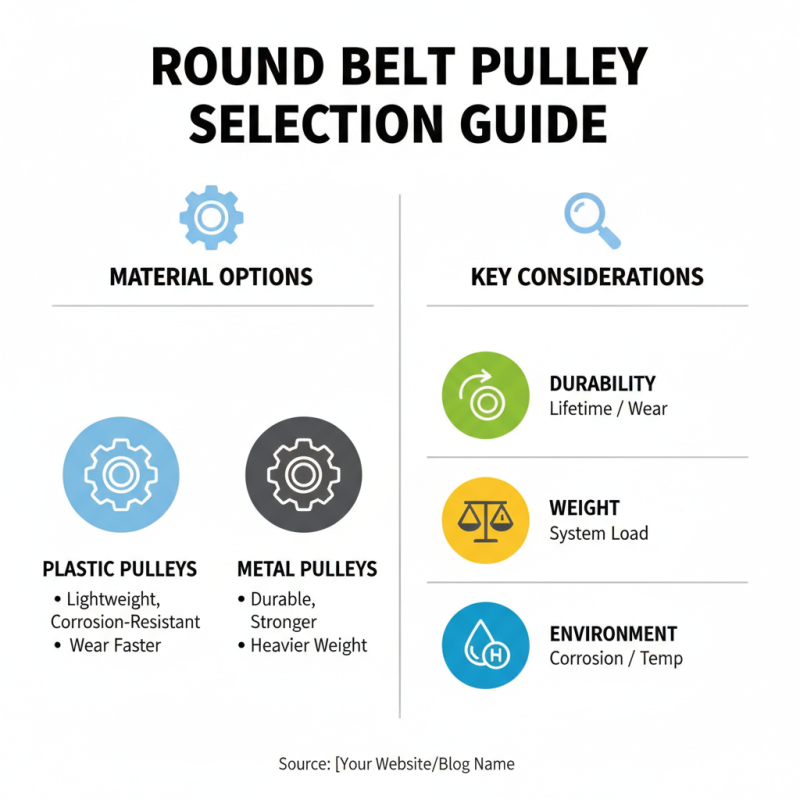

When choosing round belt pulleys, material selection is crucial. Each material offers unique benefits and drawbacks. For example, metal pulleys are strong but can be noisy. They are also heavier and may require more robust mechanisms. Conversely, plastic options are lighter and quieter but may wear out faster under heavy loads.

Rubber is another popular choice. It provides excellent grip and flexibility. However, its durability depends on the environment. High temperatures can deteriorate rubber faster than other materials. Understanding the specific needs of your project is vital. Research shows that the right material can increase efficiency by up to 30%.

Tips: Always consider the working environment. How much weight will the pulley bear? Will heat or moisture be a factor? Test materials with smaller prototypes first. This helps to avoid costly mistakes in larger applications. A small investment in testing can save time and resources later.

Reflect on what you truly need. Sometimes, the best choice may not be the obvious one. Balancing cost and performance is key. Don't overlook your specific operational needs. What works for one project may not suit another. Consider all factors before making a decision.

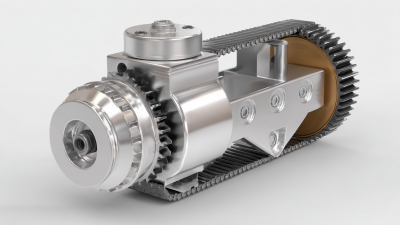

When selecting round belt pulleys for your project, several factors should be considered. The material of the pulley plays a vital role. Options range from plastic to metal, each with different strengths and weaknesses. Plastic pulleys are lightweight and resistant to corrosion but may wear out faster than metal ones. Metal pulleys provide durability, yet they may add unwanted weight.

Next, think about the size. Diameter and width can greatly impact performance. A larger diameter often allows for smoother operation. However, it can limit space in tight setups. The width must also match your project needs. If it’s too narrow, it may slip, but if too wide, it might be incompatible with your belt.

Don’t forget to evaluate the intended application. Is it for a hobby project or industrial use? Each scenario demands different specifications. Additionally, paying attention to compatibility with the belts is crucial. Misalignment may lead to failures and frustration. While researching, you'll notice imperfections, and it’s okay to reflect on them. Use those insights to refine your choices.

When choosing round belt pulleys, consider the variety of options available. Various brands offer different sizes, materials, and designs to meet unique project needs. Pulleys made from durable materials can enhance performance and longevity. Finding the right type can be challenging due to the numerous choices on the market.

Tips: Always check the specifications. Not every pulley fits every machine. A mismatch can lead to inefficiencies. Read user reviews to gauge real-world performance. They can reveal strengths and weaknesses that marketing materials often overlook.

Some models emphasize adjusting speed and torque. Others focus on minimizing noise. Each model has its pros and cons. It's vital to ensure compatibility with existing components. Sometimes, experimenting with different configurations can lead to unexpected improvements. Keep flexibility in your approach to design solutions.

| Model | Material | Diameter (inches) | Load Capacity (lbs) | Price ($) |

|---|---|---|---|---|

| Model A | Aluminum | 5 | 200 | 15.99 |

| Model B | Steel | 6 | 300 | 20.50 |

| Model C | Plastic | 4 | 150 | 12.75 |

| Model D | Iron | 7 | 400 | 25.00 |

| Model E | Carbon Steel | 8 | 500 | 30.75 |

When working with round belt pulleys, installation is crucial. Ensure the pulley aligns perfectly with the belt. Misalignment can lead to inefficiencies and premature wear. Use a level to check for accurate alignment. It’s also essential to keep the mounting surfaces clean. Dirt can disrupt the grip, causing slipping.

Regular maintenance is key to ensuring peak performance. Inspect the system frequently for wear and tear. A worn-out pulley can lead to unexpected downtime. Lubrication is another vital aspect; it reduces friction and extends the life of the components. However, too much lubrication can attract dust, causing more issues. Balance is necessary.

The environment can impact pulley performance too. Dusty or moist conditions can affect operation. Choose the right materials for your specific project conditions. Reflect on the results after installation. If you notice unusual noises or performance drops, identify the source. Improvement often comes from recognizing small issues early.