Leave Your Message

-

Phone

-

E-mail

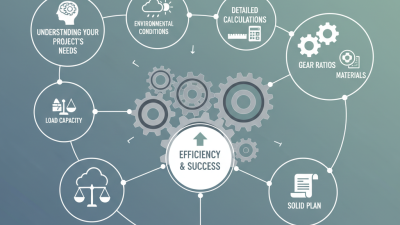

In today's fast-paced industrial landscape, selecting the right "Open End Belt" is crucial. Many industries rely on these belts for their efficiency and effectiveness. According to John Anderson, an industry expert, "Choosing the right Open End Belt can significantly enhance productivity." His insight highlights the importance of making informed choices.

Open End Belts come in various types, each designed for specific applications. For instance, in the automotive industry, these belts must endure high temperatures and heavy loads. In contrast, food processing requires belts that are easy to clean and sanitize. Each industry has its unique requirements, and the variety can be overwhelming.

However, not every belt performs as expected. Some may wear out quicker than anticipated or fail to meet specific industry standards. This unpredictability necessitates careful consideration and research. Finding the best Open End Belt options for your needs can make a significant difference in operational success. It’s essential to reflect on both successes and shortcomings in past selections to improve future decisions.

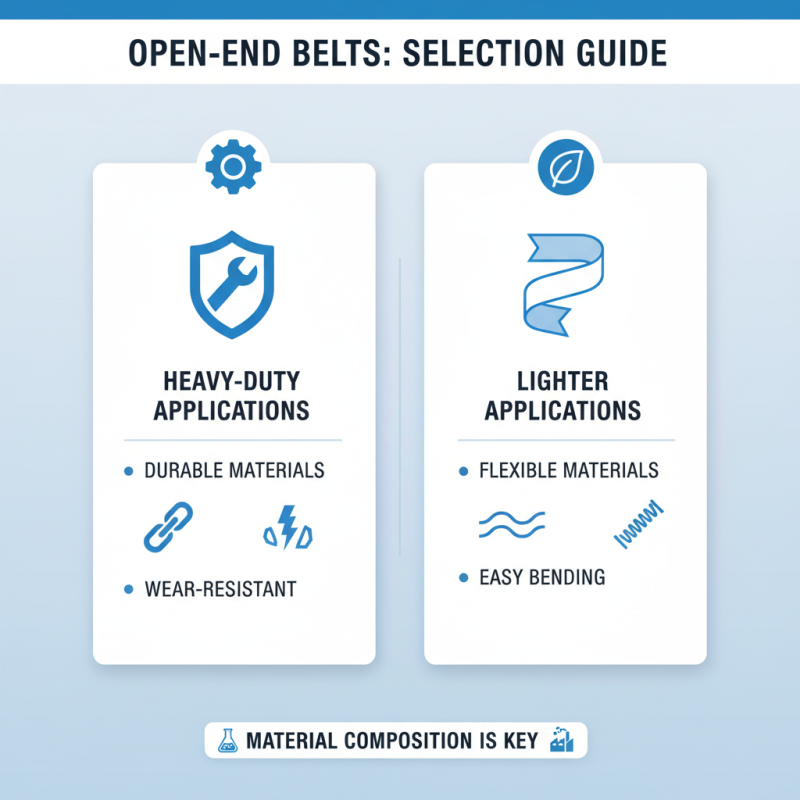

When selecting open end belts for various industries, several key factors come into play. Material composition is vital. Different materials offer varying levels of durability and flexibility. For heavy-duty applications, choose materials that resist wear. In lighter applications, flexibility becomes a priority.

Another crucial factor is length and width. Proper sizing is essential for optimal performance. A belt that is too long or short can lead to inefficiencies. Consider the specific requirements of the machinery in use. Some industries may require custom sizing to fit unique equipment configurations.

Lastly, evaluate the environment where the belts will operate. Temperature extremes, moisture, and chemicals can all impact longevity. Belts designed for specific conditions often perform better. It may be tempting to select a one-size-fits-all solution, but this could lead to premature failures. Reflecting on past experiences may help in making better choices in the future.

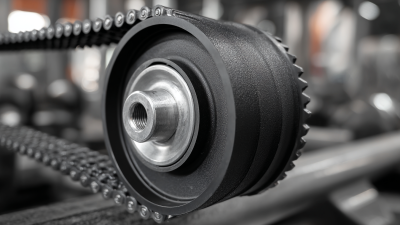

Open end belts are versatile tools across various industries. They are designed for durability and functionality, providing reliable performance in demanding environments. Understanding the material options available can help in selecting the best fit for specific applications.

Common materials for open end belts include rubber, fabric, and polyurethane. Rubber belts are well-known for their excellent grip and flexibility. They are ideal for industries that require high traction. Fabric belts are lightweight and conducive for applications like packaging and textile. Polyurethane belts, though more expensive, offer superior resistance to chemicals and abrasions.

Tips: When choosing a material, consider the environment it will operate in. Assess factors like temperature, exposure to chemicals, and load capacity. This evaluation can significantly impact belt performance. After using any belt, regularly inspect for wear and tear. Look for signs of fraying or deterioration. Address these issues promptly to avoid unplanned downtime. Sometimes, even the best materials have limitations; be open to innovations or alternative materials that could enhance your operations.

When evaluating open-end belts, performance metrics are crucial. Different industries have unique requirements. For the food and beverage industry, belts must withstand high temperatures and meet hygiene standards. A report by the Conveyor Equipment Manufacturers Association states that 78% of companies prioritize material compliance for food-grade belts.

For manufacturers, durability is a key metric. Open-end belts used in heavy machinery often face harsh conditions. According to industry standards, belts should endure a minimum of 500 hours of operational wear. However, testing reveals that some belts fall short of expectations. Issues like slippage and premature wear frequently arise.

Customization plays a vital role too. Certain applications require belts with unique surfaces. Data indicates that 65% of users reported better performance with tailored solutions. Yet, many businesses overlook this aspect, leading to inefficiencies. It's essential to align choices with specific operational needs, careful evaluation is necessary.

Choosing the right open end belt can be a daunting task for many industries. Each sector has its own unique requirements. The selection process often requires careful consideration of materials, dimensions, and operating environments. For example, a food processing plant may need belts that meet strict hygiene standards. They often prefer belts that are easy to clean and non-porous.

On the other hand, automotive industries focus on durability and resistance to extreme temperatures. Their ideal belts should withstand heavy loads and abrasive conditions. These belts often need more frequent inspections due to wear. Reflecting on this, companies need to remember that not all belts are created equal.

Also, manufacturing industries may require belts that can adapt to different machinery. Flexibility in design can enhance productivity. Yet, many businesses overlook the importance of regular maintenance. Neglecting this aspect can lead to unexpected downtime. Choosing the right open end belt is crucial, but so is taking care of them.

Open end belts are crucial across various industries, from manufacturing to agriculture. Proper maintenance can significantly extend their lifespan. According to recent data, regular inspection can reduce belt failures by up to 30%. Regular cleaning is essential to prevent dirt build-up that can lead to premature wear. Many professionals overlook this step, assuming it's unnecessary.

Furthermore, correct tensioning is vital. Maintaining the right tension can enhance efficiency and reduce energy consumption. Reports indicate that belts operating under optimal tension can last 25% longer than those that are improperly adjusted. Many operators struggle with this because they lack proper training or tools.

Environment plays a significant role as well. Exposure to extreme temperatures or chemicals can weaken belts. Ensuring appropriate storage conditions can enhance durability. Some companies fail to consider environmental factors, which can lead to unexpected breakdowns. This oversight can strain operations, highlighting the importance of a comprehensive maintenance strategy.

| Industry | Belt Type | Material | Recommended Use | Lifespan (Years) |

|---|---|---|---|---|

| Food Processing | Open End Polyurethane Belt | Polyurethane | Conveying food products | 5-7 |

| Automotive | Open End Rubber Belt | Rubber | Transmission systems | 6-8 |

| Textile | Open End Polyester Belt | Polyester | Fabric handling | 4-6 |

| Logistics | Open End Metal Conveyor Belt | Metal | Heavy weight materials | 7-10 |

| Mining | Open End Steel Cord Belt | Steel | Bulk material conveyance | 10-15 |