Leave Your Message

-

Phone

-

E-mail

In the realm of mechanical systems, the significance of belt pulleys cannot be overstated. According to Dr. John Smith, a renowned expert in mechanical engineering, “Belt pulleys are fundamental components that enable the efficient transfer of power and motion in various applications.” Their design and functionality play a critical role in a myriad of industries, from automotive to manufacturing, where precision and reliability are paramount.

Belt pulleys serve as a vital link in the transmission of energy, converting rotational motion from one shaft to another while maintaining a specific relationship between speed and torque. The interaction between the belt and the pulleys allows for smooth operation and minimal energy loss, making them indispensable in systems that rely on mechanical advantage. This introduction to belt pulleys will explore their types, workings, and the essential roles they play in optimizing mechanical performance across different sectors. As we delve into the mechanics, it becomes clear that understanding belt pulleys is key to mastering the principles of machinery and improving overall efficiency.

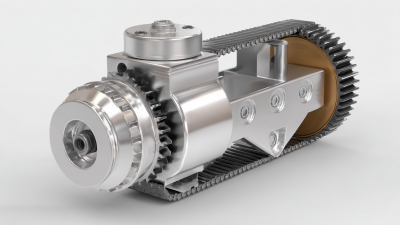

A belt pulley is a crucial component in mechanical systems, designed to transmit power and motion from one part of a machine to another. It consists of a wheel or cylinder that is grooved to accommodate a belt, allowing for the transfer of force through tension in the belt. When a driving pulley is rotated, the belt connects to a driven pulley, enabling efficient and reliable movement. This simple yet effective design is widely used in various applications, from automotive engines to industrial machinery.

The primary function of a belt pulley is to facilitate the transfer of mechanical energy with minimal friction and wear. By using a belt, the system can absorb shocks and vibrations, reducing the strain on associated components. Additionally, belt pulleys can change the direction of motion, allowing for greater flexibility in design and layout.

They can also be used to alter the speed and torque of the drive system, providing essential versatility in many engineering applications. Understanding the definition and function of belt pulleys is fundamental for anyone working in mechanical engineering or related fields.

Belt pulleys are essential components in many mechanical systems, serving various functions across different industries. The basic types of belt pulleys include fixed pulleys, movable pulleys, and compound pulleys. Fixed pulleys are primarily used to change the direction of force, while movable pulleys reduce the amount of force needed to lift heavy loads. Compound pulleys combine both types, allowing for even greater mechanical advantage. Each type has its specific applications; for example, fixed pulleys are commonly found in elevator systems, whereas movable pulleys are widely used in cranes and hoists.

In various industries, belt pulleys play a crucial role. In manufacturing, they facilitate the movement of materials along conveyor belts, ensuring efficient workflow. In automotive applications, pulleys are integral to the engine systems, helping to transfer power from the engine to the accessories. The agricultural sector also utilizes belt pulleys in machinery that helps with tasks such as irrigation and crop harvesting.

Tips: When selecting a belt pulley for your application, consider factors such as load capacity, material composition, and the operating environment. Ensuring the proper size and type of pulley can significantly enhance the efficiency and longevity of your mechanical system. Additionally, regular maintenance, including checking for wear and tear, is vital for optimal performance.

Belt pulleys play a crucial role in mechanical systems by converting rotational motion into useful mechanical work. These components are essential in numerous industries, acting as mechanical levers that transfer energy from one part of a machine to another. According to a report by the International Mechanical Engineering Society, belt-driven systems account for approximately 30% of all mechanical power transmission applications used in manufacturing processes today. This significant reliance underscores the importance of understanding how belt pulleys function in these environments.

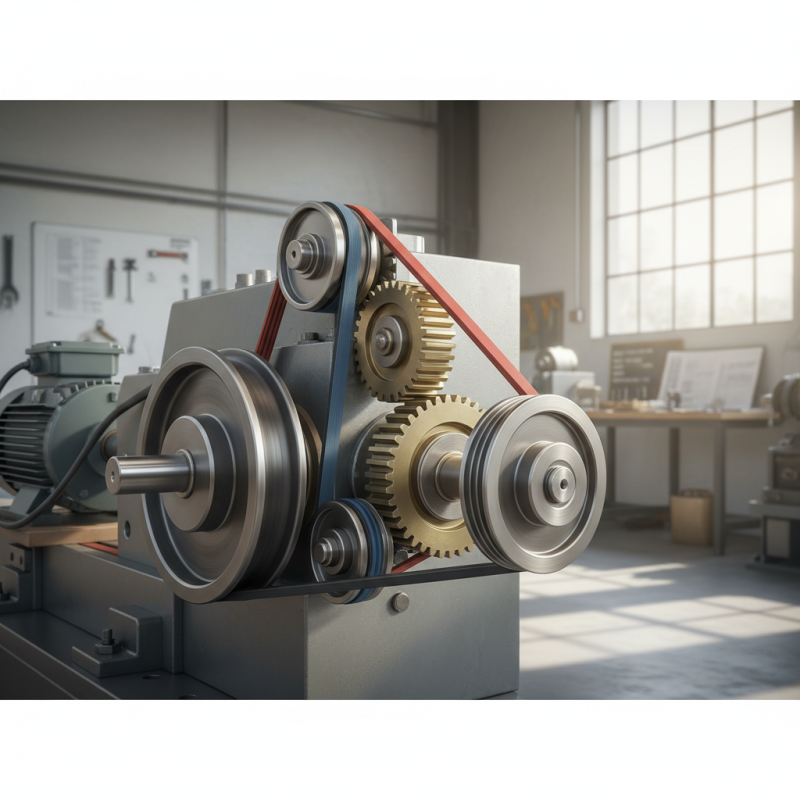

Belt pulleys operate on the principle of rotational motion transfer, where one pulley is connected to a power source, such as an electric motor. As the motor generates torque, it spins the drive pulley, causing the attached belt to move. This movement, in turn, rotates the driven pulley, which can be connected to additional machinery or components. The efficiency of this conversion can range from 90% to 98%, as noted in recent studies by the Society of Automotive Engineers. Furthermore, various factors such as pulley diameter, belt material, and tension play vital roles in optimizing performance and minimizing energy loss. By carefully designing and integrating belt pulleys into mechanical systems, industries can enhance productivity and reduce operational costs significantly.

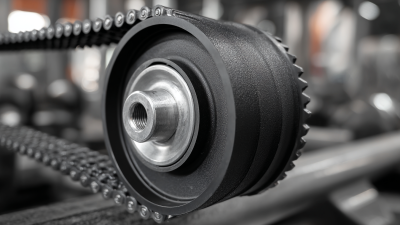

Belt pulleys are essential components in various mechanical systems, serving to transfer power and motion between different parts of machinery. However, the efficiency of a belt pulley system is heavily reliant on proper belt tension and alignment. When the belt is adequately tensioned, it ensures optimal contact with the pulley, reducing slippage and maximizing power transfer. Conversely, insufficient tension can lead to a decreased performance, resulting in energy loss and increased wear on both the belt and pulleys.

Similarly, proper alignment of the pulleys is crucial for maintaining the longevity and effectiveness of the system. Misalignment can cause uneven wear on the belt, leading to premature failure and affecting the overall operation of the machinery. To achieve alignment, it is important to regularly check the position of the pulleys and make necessary adjustments, using tools like laser alignment devices for precision.

**Tips:** To maintain ideal belt tension, consider using a tension gauge for accurate measurements. Additionally, periodically inspect the belt for signs of wear and check the alignment by sighting down the shaft to ensure that pulleys are in a straight line. Addressing these aspects not only prolongs the life of your mechanical system but also enhances its performance and reliability.

| Dimension | Value | Description |

|---|---|---|

| Pulley Diameter | 10 cm | The overall diameter of the pulley impacting speed and torque. |

| Belt Type | V-Belt | A type of belt designed to fit into a V-shaped groove on the pulley. |

| Belt Length | 150 cm | The total length of the belt used in the system. |

| Tension Force | 200 N | The force exerted by the belt to prevent slippage. |

| Alignment Accuracy | ±0.5 mm | The precision of pulley alignment affecting performance. |

| Material | Steel | The material of the pulley influencing durability and load capacity. |

| RPM (Rotations Per Minute) | 1500 RPM | The rotational speed of the pulley in operation. |

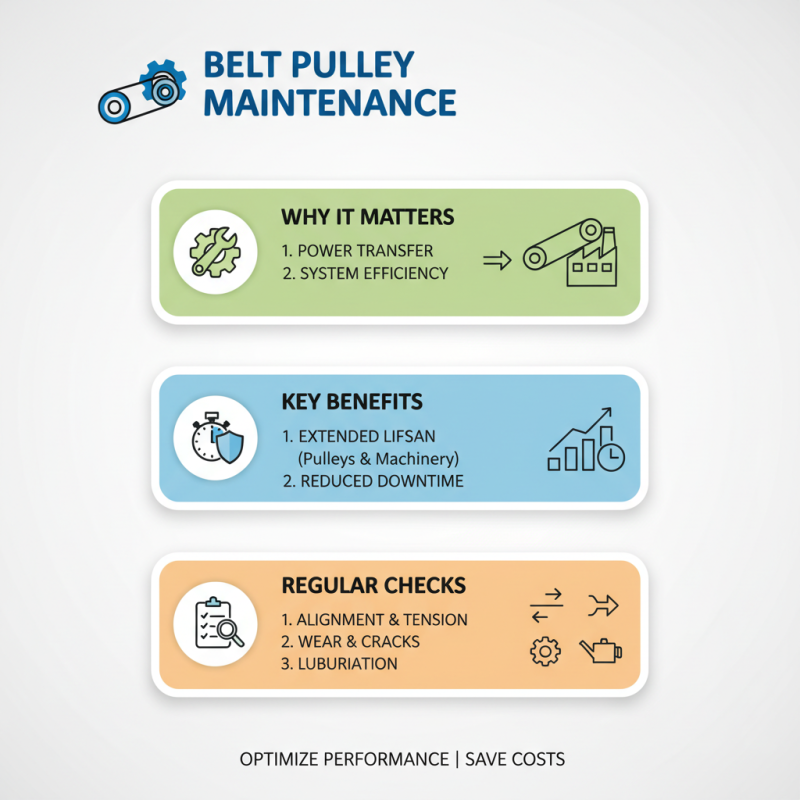

Belt pulleys are essential components in various mechanical systems, transferring power through rotating belts. To ensure these systems operate efficiently, regular maintenance of belt pulleys is crucial. This helps extend the lifespan of not only the pulleys themselves but also the entire machinery.

One important tip for optimal operation is to routinely inspect the belts for signs of wear and tear. Look for fraying, cracking, or glazing on the belt surface. If any of these issues are noticed, it is advisable to replace the belt to prevent potential slippage or failure. Additionally, ensure that the belt tension is correctly adjusted; too loose or too tight can lead to premature wear, noise, and reduced efficiency.

Another vital maintenance aspect is to keep the pulleys clean and free from debris. Dust and grime can accumulate on the surfaces, affecting performance. Regular cleaning with an appropriate solvent can help maintain optimal contact between the belt and pulley. Finally, lubricating the bearings of the pulleys, if applicable, is essential to reduce friction, enhance movement, and ultimately prolong the system's lifespan.