Leave Your Message

-

Phone

-

E-mail

The Gearbelt Pulley is essential for various machinery. Its design directly impacts performance and efficiency in mechanical systems. As industries evolve, so do the types of Gearbelt Pulleys available.

In 2026, we will see innovative designs that promise enhanced functionality. Different materials and shapes influence how these pulleys perform. Some options may prove more durable but come with a higher initial cost. Others might be affordable yet less efficient.

Selecting the right Gearbelt Pulley can be challenging. Factors like load capacity and speed ratings frequently require careful consideration. Understanding these variables is crucial for making informed decisions. Identifying the right fit can lead to significant operational improvements. Each choice presents potential benefits and drawbacks that demand reflection. The right Gearbelt Pulley can propel an operation, while the wrong one can hinder performance.

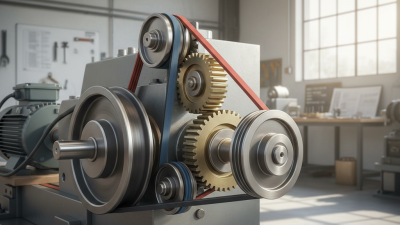

Gearbelt pulleys come in various types, each suited for specific applications. Different designs focus on optimized performance. There's a variety of materials used, such as aluminum and composites. These materials affect durability and weight.

In industrial settings, timing pulleys are commonly utilized. They provide precise motion control. You might also find v-belt pulleys in agricultural machines. They help transmit power efficiently, making them reliable in harsh environments.

Tips: Always ensure compatibility when choosing a pulley. Misalignment can cause wear and reduce efficiency. Regular inspections also help maintain performance.

For automotive applications, serpentine pulleys stand out. They drive multiple accessories with a single belt. This design saves space and weight. However, wear can occur over time, leading to slippage. Monitor these components closely to ensure they function correctly.

Pulley systems play a crucial role in enhancing performance and efficiency in various applications. The type of pulley belt you choose can significantly impact these metrics. It's essential to consider factors like material, design, and load capacity. Selecting the right pulley type can lead to improved power transmission and reduced energy loss. Often, people overlook these details, assuming any pulley will suffice.

Choosing the appropriate material for your pulley is vital. Some materials offer better durability, while others ensure flexibility under load. Steel pulleys are robust but can be heavy. Composite materials are lighter but may not withstand heavy loads as well. It's crucial to evaluate your specific needs carefully. Don’t underestimate this choice.

Tips: Always assess the working environment. Corrosive or high-temperature conditions require special materials. Regular maintenance can also prevent inefficiencies. A small error in selection can lead to significant performance issues later on. Reflect on past experiences—what worked and what didn’t? Learning from these can guide your future choices.

This chart illustrates the performance and efficiency of different types of gearbelt pulleys. The selected pulleys were analyzed based on their load capacity, efficiency percentage, and application versatility.

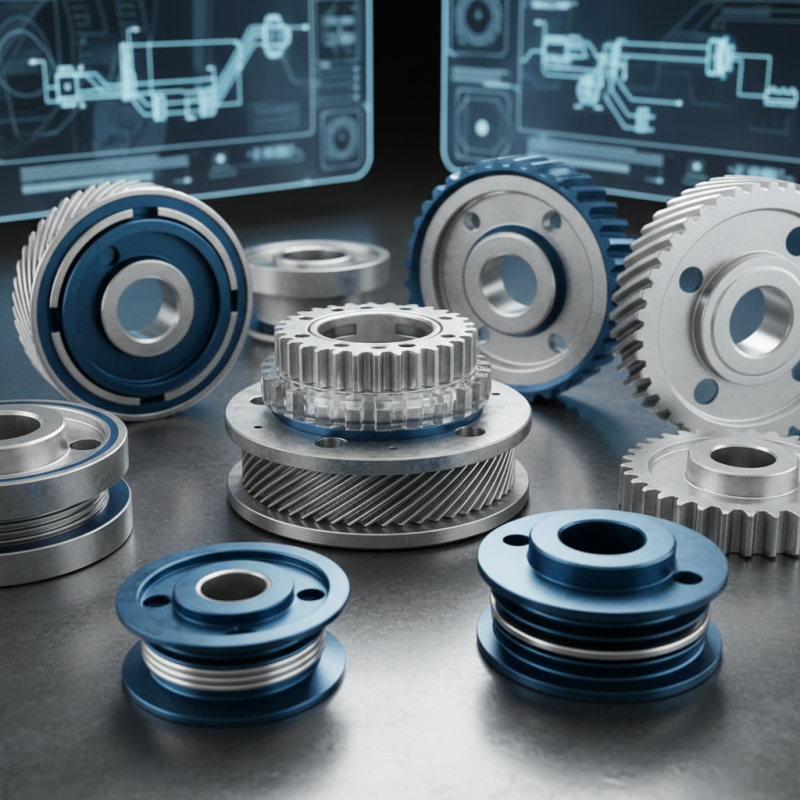

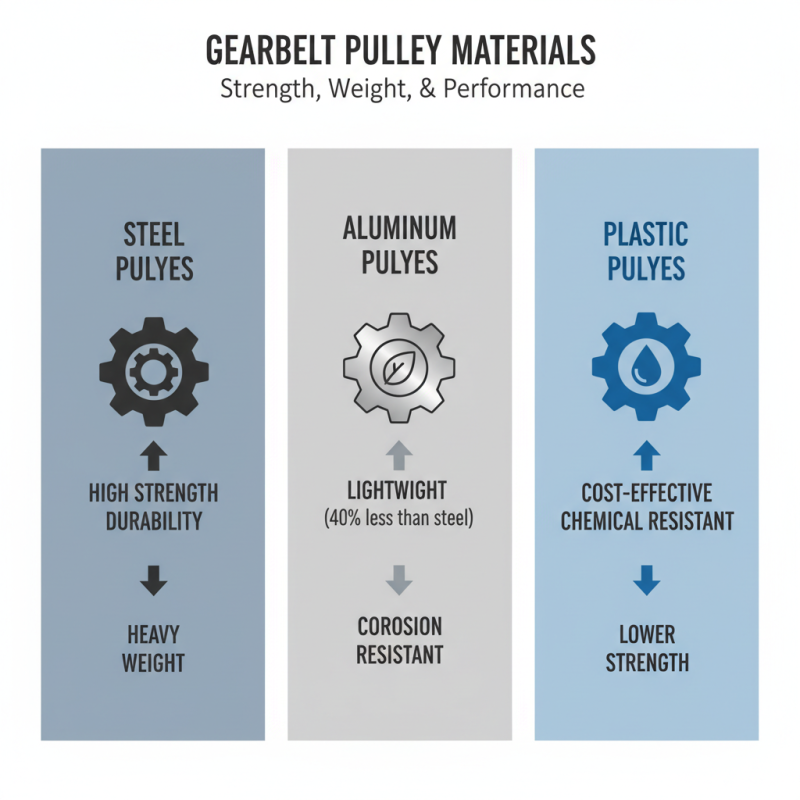

When considering gearbelt pulley materials, the most common options are steel, aluminum, and plastic. Each type has unique properties that affect performance. Steel pulleys offer strength but can be heavy. They excel in durability and wear resistance, making them a common choice in heavy-duty applications. Aluminum, on the other hand, is lighter and has good corrosion resistance. Research indicates that aluminum pulleys can reduce weight by up to 40% compared to steel, enhancing overall efficiency in dynamic systems.

Plastic pulleys have grown in popularity due to their low friction coefficients. These materials can adapt to various environmental conditions. However, they may lack the strength of metal alternatives. A recent industry report indicates that while plastic can reduce noise levels by 20%, its lifespan may be shorter than that of steel or aluminum. Engineers need to weigh these factors carefully.

Choosing the right pulley material is crucial for maximizing performance. Mistakes can lead to inefficiencies. The wear rates and weight impacts of each material show that there's no one-size-fits-all solution. Regular material testing is essential to avoid premature failures and ensure optimal function in specific applications.

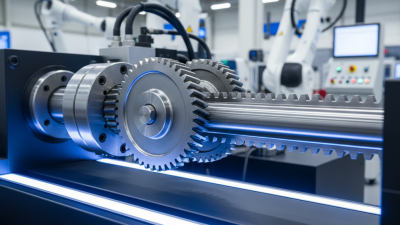

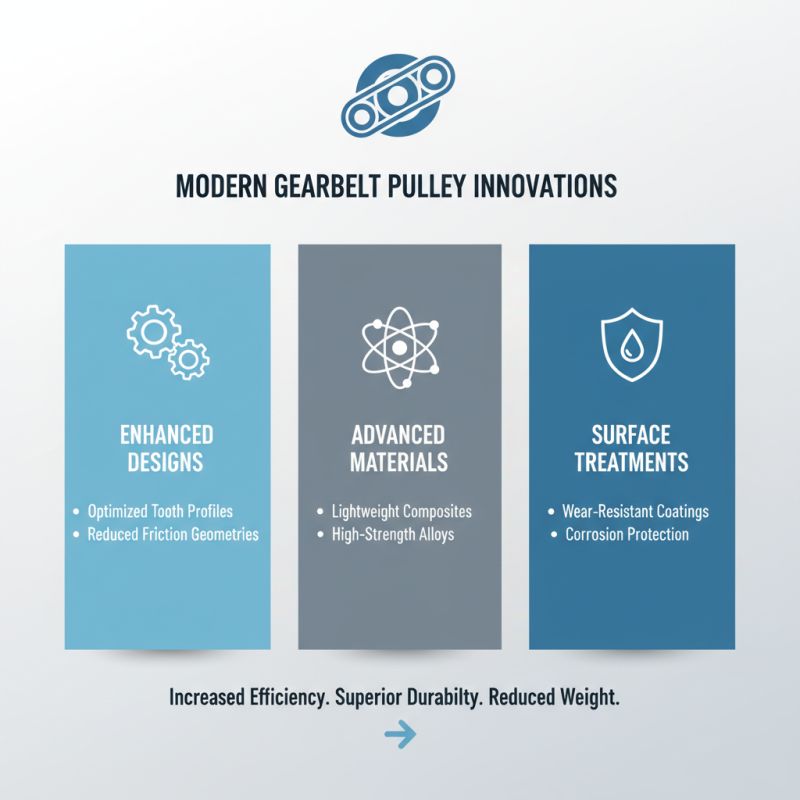

The modern gearbelt pulley has undergone significant innovation. Various designs aim to enhance performance and efficiency. The integration of advanced materials is pivotal. These materials often provide increased strength while reducing weight. Additionally, the surface treatments applied improve durability and reduce wear.

Next, consider the geometry of pulleys. Innovative shapes are emerging, focusing on optimizing belt engagement. These shapes can lead to smoother operation and less energy loss. However, the complexity in design can introduce manufacturing challenges. Engineers often need to balance efficiency with production viability.

Moreover, technology plays a crucial role. Digital simulations help in testing pulley designs before physical production. Yet, relying too heavily on technology can overlook real-world conditions. Sometimes, traditional methods offer insights that modern tech fails to capture. It's a fine line between embracing innovation and understanding the value of practical experience.

Maintaining gearbelt pulleys is crucial for optimal performance. Regular maintenance can enhance efficiency and prolong their lifespan. According to industry reports, approximately 30% of mechanical failures are linked to improper pulley maintenance.

Pay attention to alignment. Misalignment can cause excessive wear. Regularly check alignment using a laser alignment tool. This might sound too technical, but it's essential. Moreover, ensure that tensions are within specified limits. Over-tightening can lead to premature wear. It’s important to have a tension gauge on hand.

Lubrication matters, but too much lubricant can attract dirt. Use the right type of lubricant. A high-quality lubricant enhances performance but should be applied sparingly. Scheduling regular inspections every six months helps catch issues early. Ensure visual checks are part of your routine. Look for signs of wear or damage. Small cracks or fraying belts indicate it’s time for replacement. Reflecting on these aspects can lead to significant improvements in efficiency and reduced downtime.

| Pulley Type | Material | Diameter (mm) | Weight (kg) | Efficiency Rating | Maintenance Frequency |

|---|---|---|---|---|---|

| Standard Pulley | Steel | 150 | 1.2 | 85% | Every 6 months |

| High-Performance Pulley | Aluminum | 120 | 0.8 | 92% | Every 3 months |

| Variable Diameter Pulley | Plastic | 100 | 0.5 | 80% | Every 12 months |

| Sealed Pulley | Stainless Steel | 140 | 1.5 | 90% | Every 4 months |

| Compact Pulley | Composite | 80 | 0.3 | 75% | Every 18 months |