Leave Your Message

-

Phone

-

E-mail

In the world of industrial machinery, understanding the various types of V Belt Pulleys is crucial for optimizing operational efficiency and performance. According to renowned industry expert John Anderson, “The right V Belt Pulley can significantly enhance the longevity and reliability of machinery.” This statement underscores the pivotal role that V Belt Pulleys play in driving systems, allowing for the smooth transfer of power and motion across gears and belts.

As we delve into the essential guide for 2025, it becomes clear that not all V Belt Pulleys are created equal. With a diverse range of types available—from standard to specialized designs—each serves specific applications and operational needs. Selecting the appropriate V Belt Pulley not only ensures effective machinery function but also helps in minimizing wear and tear, setting the stage for more efficient maintenance practices.

This guide intends to equip readers with the knowledge necessary to choose the most suitable V Belt Pulley for their machinery. By understanding the unique characteristics and benefits of different types, users can make informed decisions, ultimately boosting productivity and extending the lifespan of their equipment.

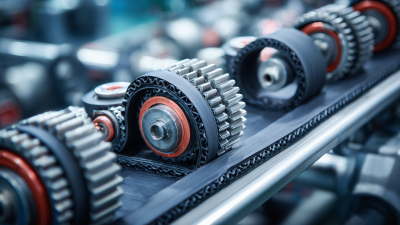

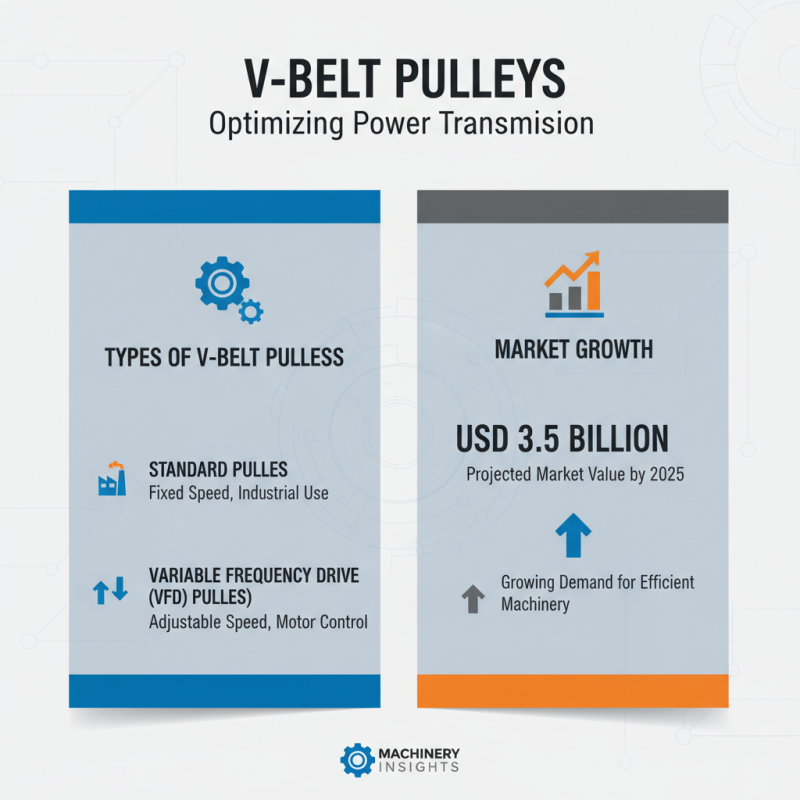

V-belt pulleys are critical components in various machinery, facilitating power transmission between shafts and optimizing mechanical performance. A comprehensive overview of types of V-belt pulleys showcases their diversity and application across industries. The most common types includeStandard Pulleys, which are designed to fit specific V-belt sizes and are widely used in industrial settings, and Variable Frequency Drive (VFD) Pulleys, which allow for speed adjustments in systems requiring variable motor speeds. According to a report by Markets and Markets, the V-belt pulley market is projected to reach USD 3.5 billion by 2025, signifying a growing demand for efficient and adaptable machinery solutions.

Another notable type is the stepped or multi-groove pulley, which can accommodate multiple V-belt sizes while also enabling the user to optimize torque and speed. This versatility is particularly beneficial in agricultural machinery and manufacturing equipment, where varying loads are common. The increase in automation in industries is expected to drive demand for such pulleys, as highlighted by a study from Grand View Research that anticipates a compound annual growth rate (CAGR) of 4.2% in the mechanical power transmission market through 2025. Understanding these types of V-belt pulleys will aid manufacturers and engineers in selecting the right components for peak operating efficiency.

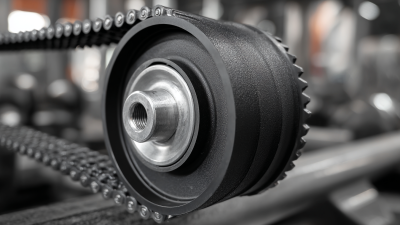

Understanding the components of V Belt pulley systems is crucial for the optimal performance of various machinery. At the core of these systems is the V belt itself, which is designed to transfer power between pulleys while maintaining a secure fit. The unique trapezoidal cross-section of the V belt allows for maximum grip on the pulley, reducing slippage and increasing efficiency. Additionally, the tension within the system must be carefully monitored; too loose a belt can lead to inefficiencies, while overly tight belts can cause premature wear on both the belt and pulleys.

Pulleys come in various types, each designed for specific applications. The grooved pulley is commonly used in standard V belt setups, ensuring a tight fit and effective power transfer. In contrast, adjustable pulleys offer flexibility, allowing for changes in belt tension as needed. Understanding these different types, along with their respective applications, helps engineers and technicians optimize machinery for specific tasks. Each component plays a vital role in the overall functionality and durability of the system, making it essential to select the right parts for various mechanical requirements.

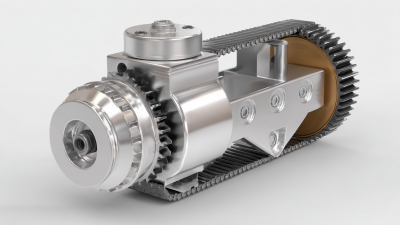

Selecting the right V belt pulley type is crucial for ensuring the efficient operation of machinery. One of the primary factors to consider is the application requirements. Different machines demand varying torque levels, speeds, and load capacities. Understanding these specifications helps in choosing a pulley that matches the design of the machinery while optimizing performance. For instance, a pulley designed for high-speed applications must be able to handle dynamic loads without excessive wear, while one for lower speeds may prioritize durability over speed.

Another key factor is the material used in the construction of the pulley. Common materials include aluminum, cast iron, and reinforced plastics, each offering distinct advantages depending on the operating environment. For instance, aluminum pulleys are lightweight and corrosion-resistant, making them suitable for machines operating in moist environments. On the other hand, cast iron pulleys provide excellent strength and wear resistance, which can be critical in heavy-load applications. Additionally, considering the dimensions, such as the pulley’s diameter and groove design, is essential to ensure compatibility with the belt system and to achieve the desired power transmission efficiency.

| Pulley Type | Material | Belt Size Range (inches) | Load Capacity (lbs) | Efficiency (%) |

|---|---|---|---|---|

| Standard V-Belt Pulley | Cast Iron | 2 - 12 | 1000 | 95 |

| Heavy-Duty V-Belt Pulley | Steel | 4 - 16 | 2500 | 90 |

| Lightweight V-Belt Pulley | Aluminum | 1 - 8 | 800 | 92 |

| Variable Speed V-Belt Pulley | Cast Iron | 3 - 10 | 1500 | 88 |

| Taper Lock V-Belt Pulley | Steel | 2 - 14 | 1200 | 93 |

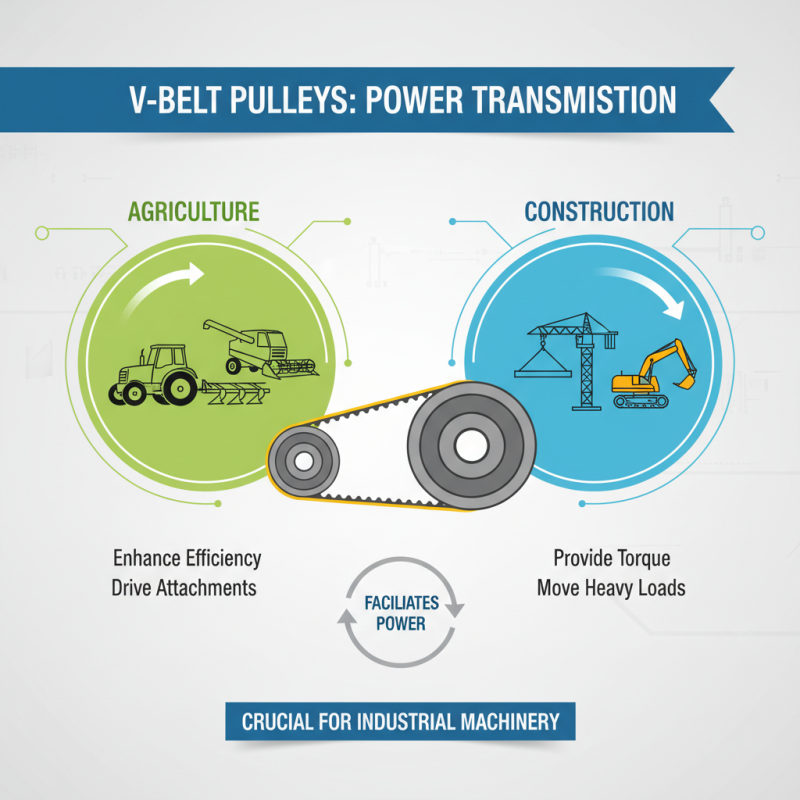

V belt pulleys play a crucial role in various industries by facilitating power transmission in machinery. These components are commonly found in agricultural equipment, where they help drive different attachments such as plows and harvesters. The use of V belt pulleys in farming machinery enhances efficiency and productivity, allowing for effective operation across vast fields. Similarly, in the construction sector, these pulleys are essential for heavy machinery like cranes and excavators, providing the necessary torque to lift and move substantial loads.

In addition to agriculture and construction, V belt pulleys are widely utilized in manufacturing and automotive industries. In manufacturing settings, they are integral to conveyor belt systems, ensuring smooth movement of materials and products through different stages of production. The automotive industry also relies on these pulleys for various applications, such as in engines to manage the operation of alternators and water pumps, which is vital for maintaining vehicle performance. Overall, V belt pulleys are indispensable components across numerous sectors, highlighting their versatility and importance in modern machinery.

Effective maintenance of V belt pulleys is crucial for maximizing the performance and longevity of machinery. According to a report from the International Organization for Standardization (ISO), improper maintenance can reduce operational efficiency by as much as 30%. Regular inspections are essential to identify wear and tear, as well as misalignment issues that can lead to premature failure. A meticulous approach to checking the condition of the belts, along with ensuring proper tension, helps prevent slippage and minimizes energy loss, which is vital in industrial settings where every percentage of efficiency counts.

Additionally, lubrication plays a significant role in the upkeep of V belt pulleys. The Machinery Lubrication Journal highlights that excessive friction can lead to heat generation, resulting in material degradation. Implementing a routine lubrication schedule not only enhances pulley life but also maintains optimal functionality under varying load conditions. Furthermore, it's important to monitor operating conditions such as temperature and environmental exposure, as these factors can influence maintenance frequency. Regular data collection on machinery performance can assist in developing a proactive maintenance plan that emphasizes the health of V belt pulleys, ensuring machinery operates at peak performance levels.